Key technology and formula for lonicera edulis, raspberry and wild blueberry compound beverage

A technology of wild blueberry and blueberry fruit, applied in the field of beverage processing, can solve the problems of inability to meet market demand, short shelf life of small berries, collection and other problems, and achieve the effects of increasing resource utilization, process control, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

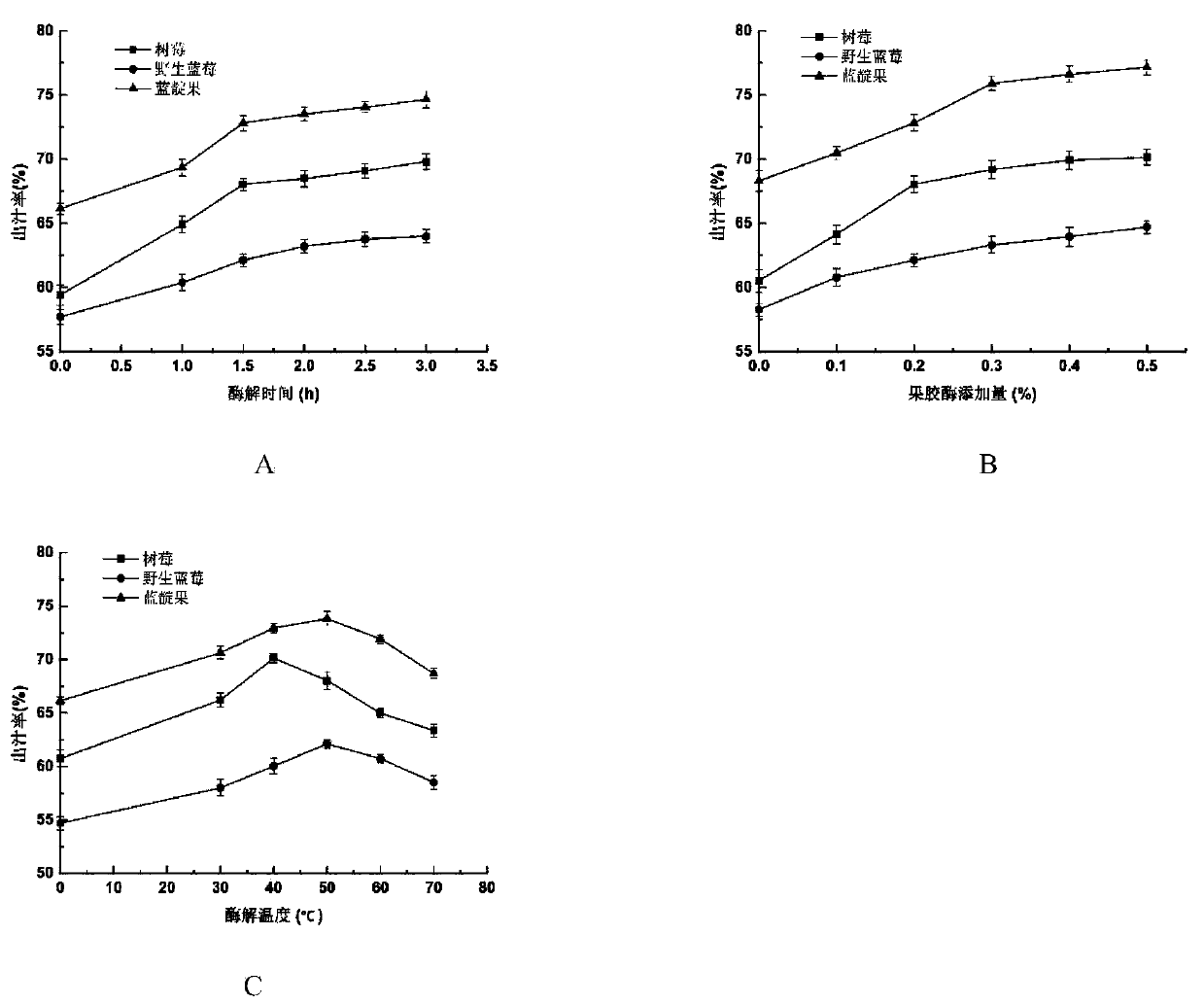

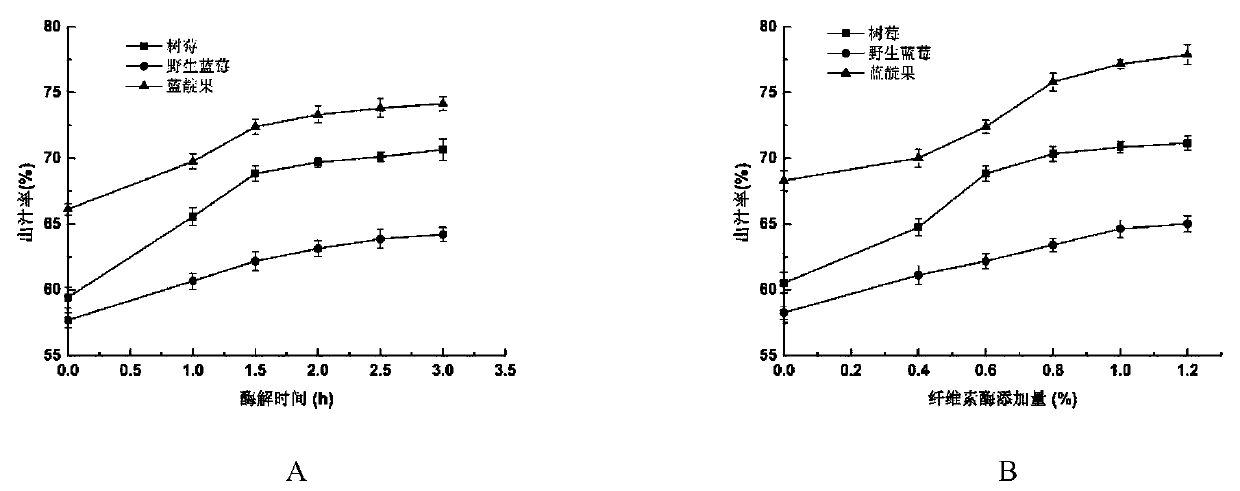

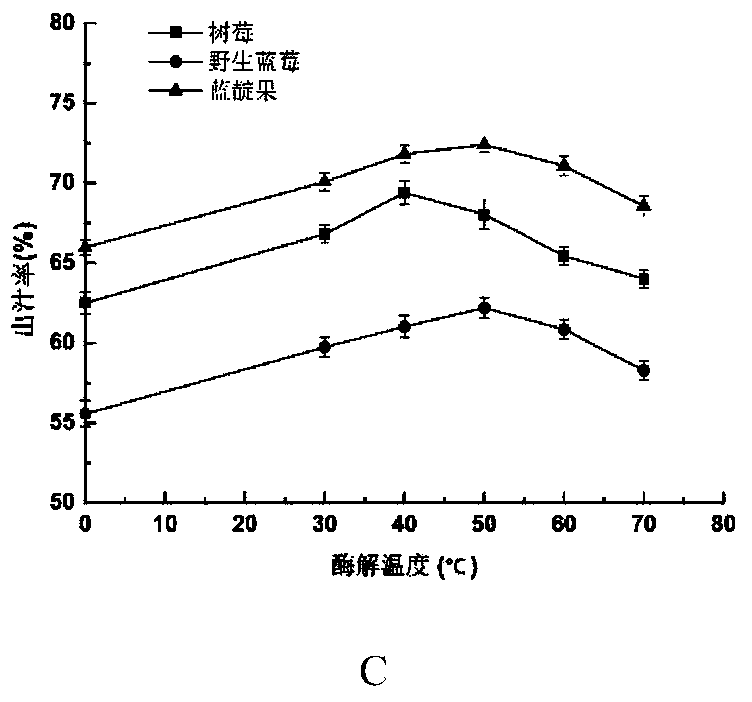

Embodiment 1

[0044] Fully thaw frozen raspberries, wild blueberries and blueberries at room temperature, and select small berries with uniform size and color; no rotten, immature green fruits, pests and diseases, no branches, leaves, insects, stones, etc.; wash them thoroughly with running water ; Beat the washed three small berries with a beater; add 0.26% pectinase and 0.92% cellulase to the raspberry pulp, and enzymolyze it at 47°C for 2 hours; add pectin to the wild blueberry pulp Enzyme 0.26%, cellulase 0.92%, enzymatic hydrolysis at 50°C for 2 hours; add pectinase 0.27%, cellulase 0.92% to the pulp of blue indigo fruit, and enzymolyze at 45°C for 2h; The three pulps are filtered and centrifuged separately to obtain three clarified small berry juices; 20% raspberry juice, 5% wild blueberry juice, 10% blueberry juice, 9% white sugar; stable The agent CMC is 0.20%, gellan gum is 0.11% and xanthan gum is 0.06%, and the rest are all prepared with pure water and stirred evenly; before homo...

Embodiment 2

[0046] Fully thaw the frozen raspberries, wild blueberries and blueberries at room temperature, and select small berries with uniform size and color; no rotten, immature green fruits, pests and diseases, no branches, leaves, insects, stones, etc.; wash them thoroughly with running water ; Beat the washed three small berries with a beater; add 0.20% pectinase and 0.90% cellulase to the raspberry pulp, and enzymolyze it at 45°C for 2 hours; add pectin to the wild blueberry pulp Enzyme 0.26%, cellulase 0.92%, enzymatic hydrolysis at 48°C for 1.5h; add pectinase 0.27%, cellulase 0.92% to the indigo pulp, and enzymolyze at 47°C for 2h; The three kinds of fruit slurries were filtered and centrifuged separately to obtain three kinds of clarified small berry juice; according to 15% raspberry juice, 5% wild blueberry juice, 10% blueberry juice, and 10% white sugar; The stabilizer CMC is 0.22%, the gellan gum is 0.11%, and the xanthan gum is 0.06%. The rest are all prepared with pure wa...

Embodiment 3

[0048]Fully thaw frozen raspberries, wild blueberries and blueberries at room temperature, and select small berries with uniform size and color; no rotten, immature green fruits, pests and diseases, no branches, leaves, insects, stones, etc.; wash them thoroughly with running water ; beat the washed three small berries with a beater; add 0.26% pectinase and 0.92% cellulase to the raspberry pulp, and enzymolyze it at 47°C for 1.5h; add fruit juice to the wild blueberry pulp Gelase 0.26%, cellulase 0.92%, enzymatic hydrolysis at 40°C for 2 hours; add pectinase 0.27%, cellulase 0.92% to the indigo fruit pulp, and enzymolysis at 50°C for 2h; The three kinds of fruit slurries were filtered and centrifuged separately to obtain three clarified small berry juices; according to 20% raspberry juice, 5% wild blueberry juice, 8% blueberry juice, and 10% white sugar; The stabilizer CMC is 0.20%, the gellan gum is 0.11%, and the xanthan gum is 0.05%. The rest are all prepared with pure wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com