Precise ammonia spraying device and method for thermal power plant denitration SCR reactors

A technology for SCR reactors and thermal power plants, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as lag, long pipelines, and large ammonia escape, and achieve the effect of large sampling range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

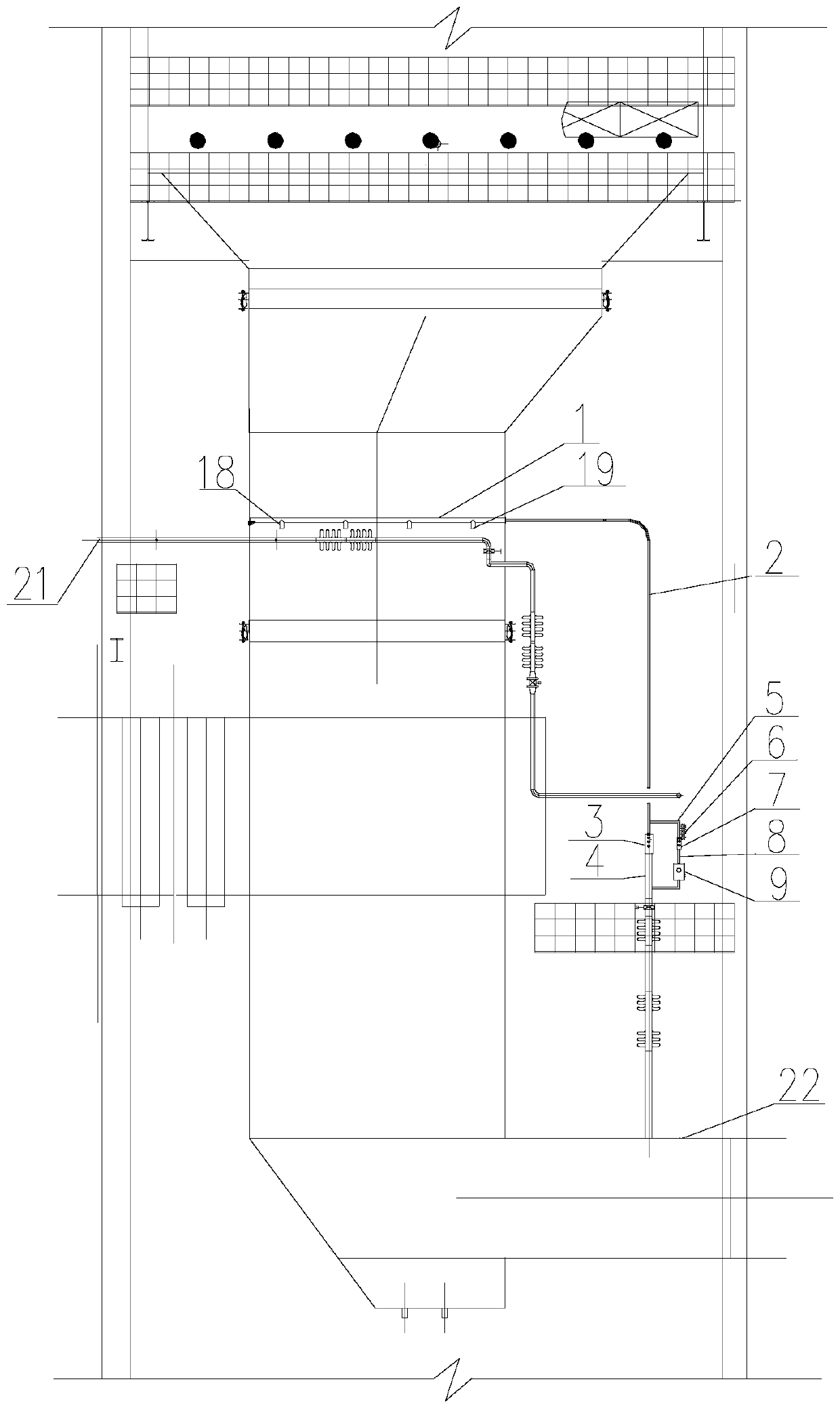

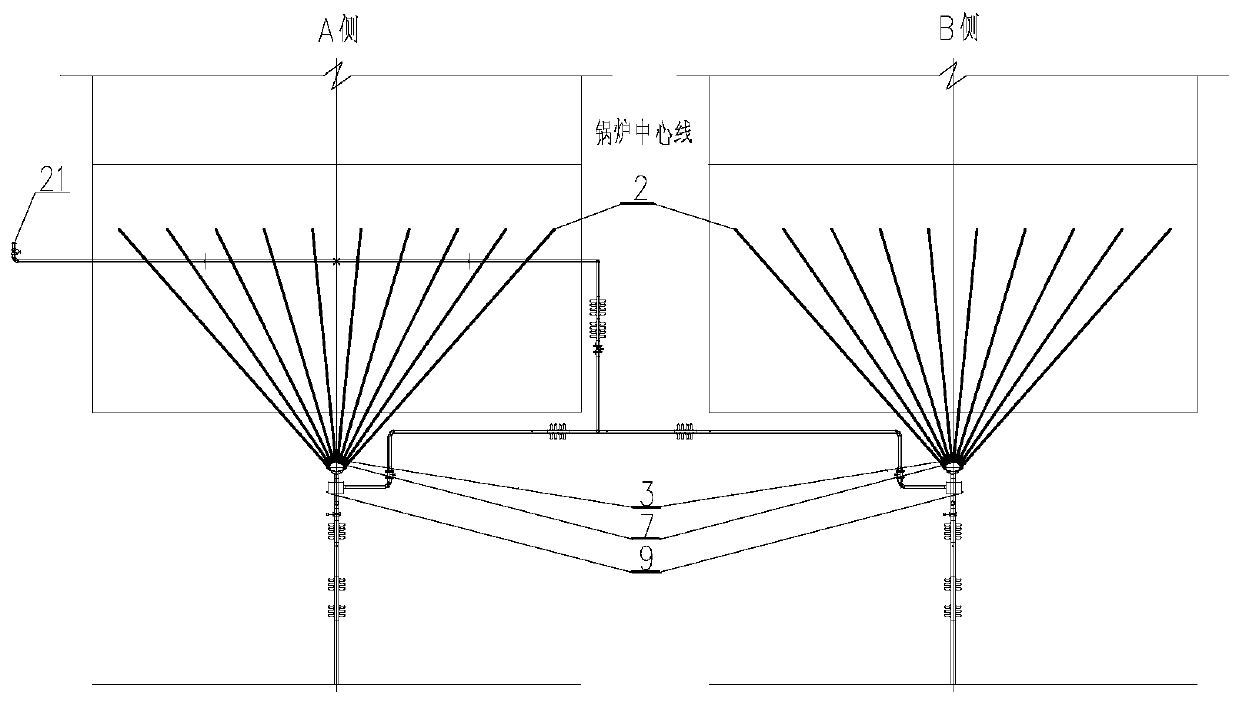

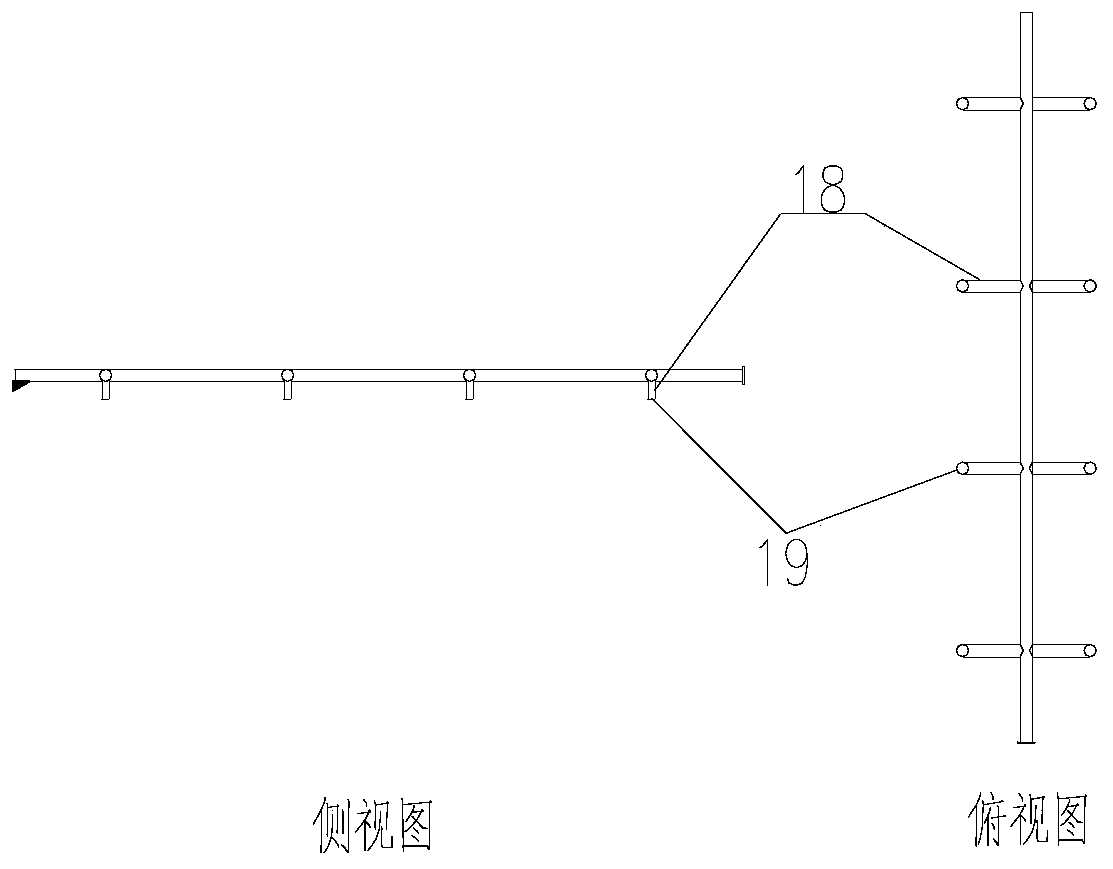

[0037] Embodiment 1 of the present invention: as Figure 1-5 As shown, a precision ammonia injection device for denitrification SCR reactor in a thermal power plant includes an SCR reactor, a flue gas extraction analysis system and an ammonia injection grid partition system. The flue gas extraction analysis system is arranged at the outlet of the SCR reactor. Including the flue internal sampling pipe system and the flue external analysis system; the flue internal sampling pipe system includes 10 samplers 1, 10 sampling branch pipes 2 connected to the sampler 1, and the sampling branch pipes 2 are converged and connected to the sampling mixer 3 , the other end of the sampling mixer 3 is connected to the sampling mixing pipe 4, and the flue gas is connected to the inlet flue 22 of the air preheater through the sampling mixing pipe 4; Mixer 7, the other end of the analysis mixer 7 is sequentially connected to the analysis mixing pipe 8 and the analyzer 9; the inlet of the analysi...

Embodiment 2

[0043] Embodiment 2: as figure 1 , 2 As shown in and 4, a precision ammonia injection device for denitrification SCR reactor in a thermal power plant includes an SCR reactor, a flue gas extraction analysis system and an ammonia injection grid partition system, and the flue gas extraction analysis system is arranged at the outlet of the SCR reactor place, including the internal sampling pipe system of the flue and the analysis system outside the flue; the internal sampling pipe system of the flue includes 12 samplers 1, and 12 sampling branch pipes 2 connected to the sampler 1, and the sampling branch pipes 2 are converging and connected to the sampling mixing 3, the other end of the sampling mixer 3 is connected to the inlet flue 22 of the air preheater; the analysis system outside the flue includes 12 analysis branch pipes 5, the analysis branch pipes 5 are converged and connected to the analysis mixer 7, and the other end of the analysis mixer 7 is connected to Analyzer 9; ...

Embodiment 3

[0044] Embodiment 3: as Figure 1-4 As shown, a precision ammonia injection device for denitrification SCR reactor in a thermal power plant includes an SCR reactor, a flue gas extraction analysis system and an ammonia injection grid partition system. The flue gas extraction analysis system is arranged at the outlet of the SCR reactor. Including flue internal sampling pipe system and flue external analysis system; said flue internal sampling pipe system includes 8 samplers 1, 8 sampling branch pipes 2 connected with sampler 1, sampling branch pipes 2 converged and connected to sampling mixer 3 , the other end of the sampling mixer 3 is connected to the inlet flue 22 of the air preheater; the analysis system outside the flue includes 8 analysis branch pipes 5, the analysis branch pipes 5 are converged and connected to the analysis mixer 7, and the other end of the analysis mixer 7 is connected to the analyzer 9; the inlet of the analysis branch pipe 5 is arranged on the pipeline...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com