Preparation method and application of Co3S4 @ MoS2 core-shell structure nano-sheet array material

A technology of nanosheet array and core-shell structure, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as difficult to meet application requirements, small active specific surface area, low energy density, etc., to increase electrochemical Active sites, low cost, and the effect of improving specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

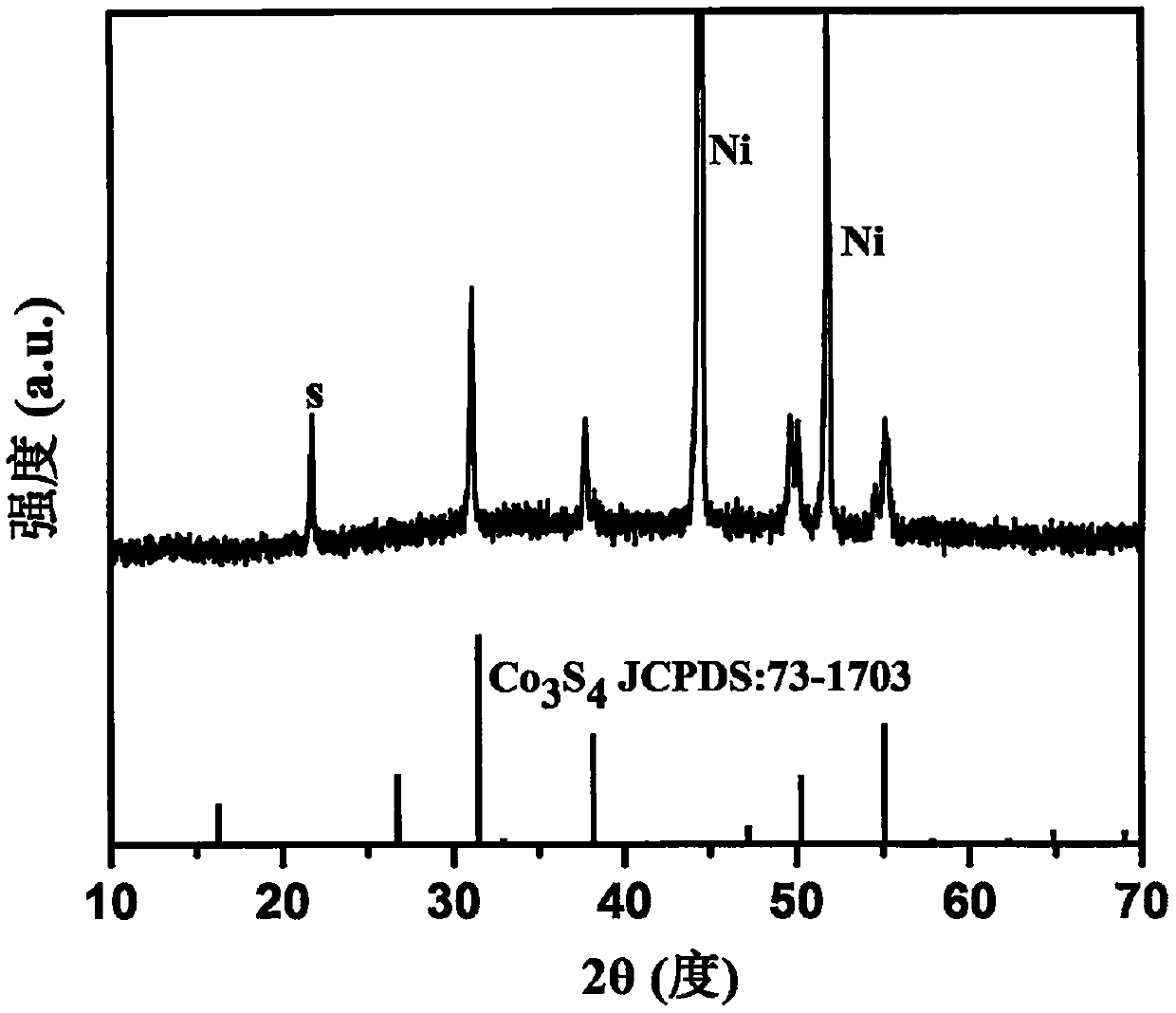

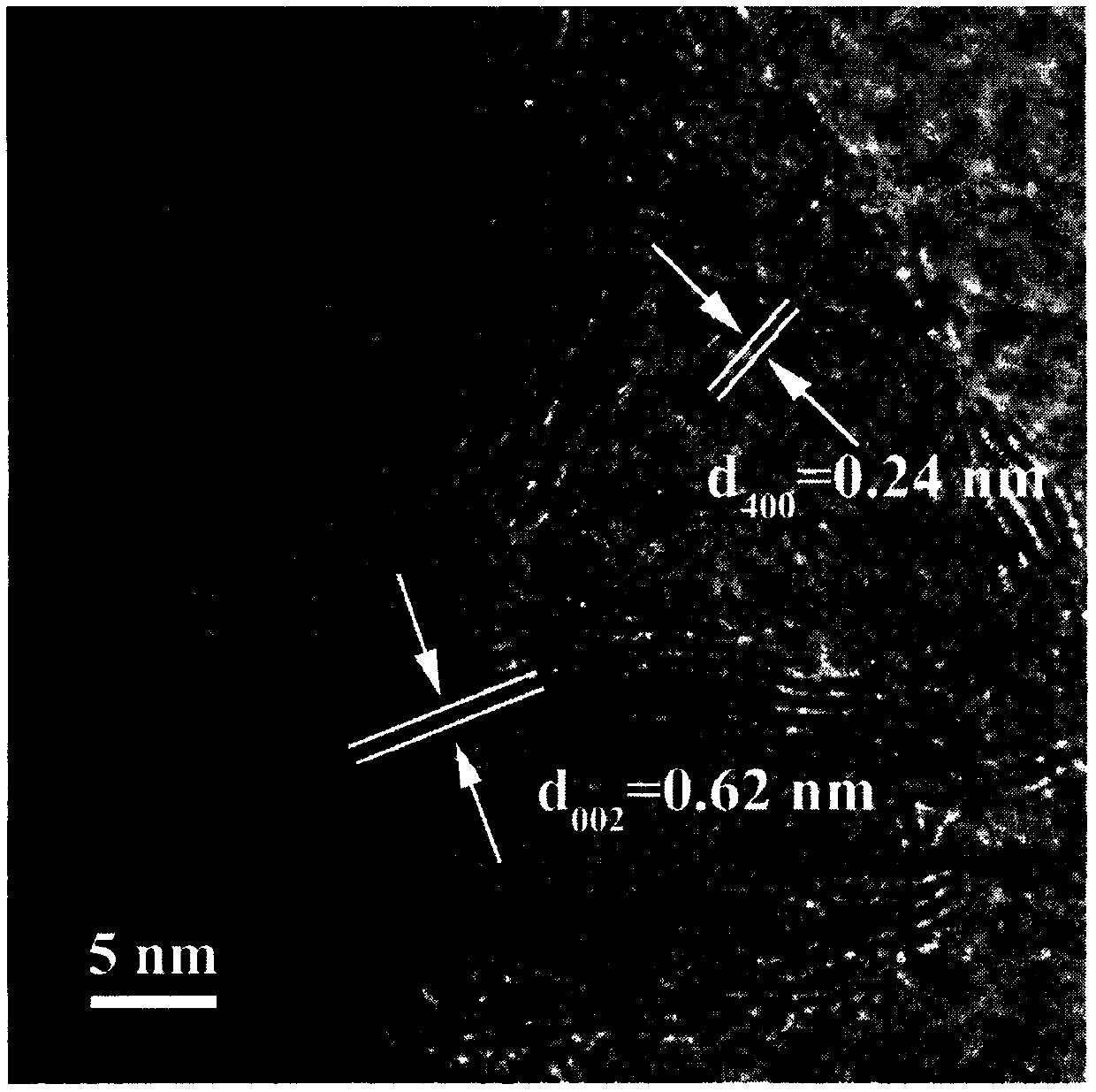

[0027] A kind of Co 3 S 4 @MoS 2 A method for preparing a core-shell structure nanosheet array material, comprising the following steps:

[0028] (1) Put the nickel foam with impurities on the surface into acetone, deionized water and ethanol to ultrasonically clean it for 20 minutes, and dry it in a blast drying oven at 60°C for 12 hours;

[0029] (2) Weigh 10mmol cobalt nitrate hexahydrate and 120mmol dimethylimidazole and dissolve them in 40ml of deionized water respectively. After the two solutions are mixed, put the nickel foam treated in step (1) into the solution, react for 4h at room temperature, and dissolve them in water. After washing several times and drying in an oven at 60 °C for 12 h, Co 3 S 4 @MoS 2 Precursor;

[0030] (3) Weigh 16mmol of sodium molybdate dihydrate and 16mmol of thioacetamide dissolved in 30ml of absolute ethanol and sonicate for 20min, put the precursor obtained in step (2) into the above solution, and heat at 120°C for 4, Then heated a...

Embodiment 2

[0034] A kind of Co 3 S 4 @MoS 2 Application of core-shell structure nano-array materials as electrode materials for supercapacitors.

[0035] The specific application method is: with Co 3 S 4 @MoS 2 The core-shell structure nano-array material is used as the positive electrode, the platinum wire is used as the counter electrode, and the calomel is used as the reference electrode to assemble a three-electrode system supercapacitor. With 1M KOH solution as the electrolyte, the cyclic voltammetry curve is measured using a CHI 660E electrochemical workstation. Current charge and discharge and charge and discharge cycle curves. The test of the cyclic voltammetry curve is carried out at the scanning speed of 5, 10, 20, 30, 50 and 100mV / s, and the voltage range is -0.4~0.7V. The results are as follows: Figure 5 As shown, the cyclic voltammetry curves still show similar shapes even at a large scan rate, which indicates that the electrode material has good reversibility and rat...

Embodiment 3

[0037] A kind of Co 3 S 4 @MoS 2 A method for preparing a core-shell structure nano-array material, comprising the following steps:

[0038] (1) Put the nickel foam with impurities on the surface into acetone, deionized water and ethanol to ultrasonically clean it for 20 minutes, and dry it in a blast drying oven at 60°C for 12 hours;

[0039] (2) Take by weighing 10mmol cobalt nitrate hexahydrate and 120mmol dimethylimidazole and dissolve in 40ml of deionized water respectively, after mixing the two solutions, put the nickel foam processed in step (1) into, and react for 4h at room temperature, Washed several times with water and dried in an oven at 60 °C for 12 h to obtain Co 3 S 4 @MoS 2 Precursor;

[0040] (3) Weigh 24mmol of sodium molybdate dihydrate and 36mmol of thioacetamide dissolved in 30ml of absolute ethanol and sonicate for 20min, put the precursor obtained in step (2) into the above solution, heat at 110°C for 3h, Then heated at 200°C for 8h, and cooled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com