Manufacturing method of flow-separated ball carrier for sewage treatment

A sewage treatment and production method technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems of complex structure and shape, difficult production and processing, high cost of raw materials, etc., to achieve Low cost, strong hydrophilic performance, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 A method for making a floating ball carrier for sewage treatment, comprising the following steps:

[0028] ⑴ According to weight percentage (kg), mix 77% of laterite, 12% of slaked lime powder, 7% of hemihydrate gypsum powder, and 4% of cement, and mix well to obtain the mixture.

[0029] (2) Add 0.3 times the weight of water to the mixture to make mud.

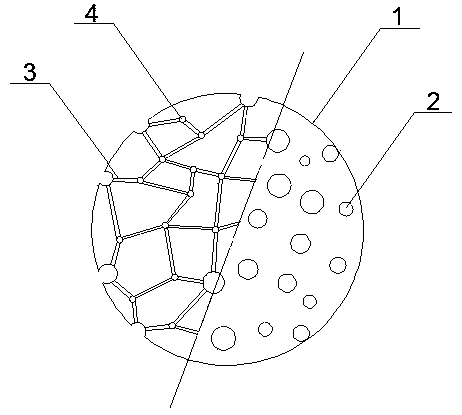

[0030] (3) The mud material is put into the hollow part of the floating ball mold with the steel needle 6, extruded or pressed to shape, and the steel needle 6 is drawn out to obtain the finished floating ball carrier 3 with the recess 2, the honeycomb hole and the channel space 4.

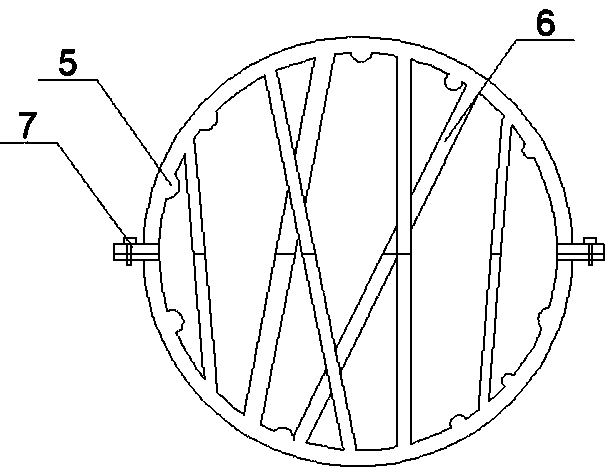

[0031] Wherein: the drift ball mold comprises a pair of hemispherical shells (see figure 2 ). The shell is provided with a convex hole 5, and the hollow part inside is provided with a steel needle 6 with a diameter of 3 mm. The shell refers to a spherical mold with a diameter of 80mm.

[0032] (4) The finished product of ...

Embodiment 2

[0033] Embodiment 2 A method for making a floating ball carrier for sewage treatment, comprising the following steps:

[0034] ⑴ According to weight percentage (kg), mix 86% of laterite, 7% of slaked lime powder, 4% of hemihydrate gypsum powder, and 3% of cement, and mix well to obtain the mixture.

[0035] (2) Add 0.4 times the weight of water to the mixture to make mud.

[0036] (3) The mud material is put into the hollow part of the floating ball mold with the steel needle 6, extruded or pressed to shape, and the steel needle 6 is drawn out to obtain the finished floating ball carrier 3 with the recess 2, the honeycomb hole and the channel space 4.

[0037] Wherein: the drift ball mold comprises a pair of hemispherical shells (see figure 2 ). The shell is provided with a convex hole 5, and the hollow part inside is provided with a steel needle 6 with a diameter of 15 mm. The shell refers to a spherical mold with a diameter of 100mm.

[0038] (4) The finished product of...

Embodiment 3

[0039] Embodiment 3 A method for making a floating ball carrier for sewage treatment, comprising the following steps:

[0040] ⑴ According to weight percentage (kg), mix 80% of laterite, 10% of slaked lime powder, 5% of hemihydrate gypsum powder, and 5% of cement, and mix well to obtain the mixture.

[0041] (2) Add 0.35 times the weight of water to the mixture to make mud.

[0042] (3) The mud material is put into the hollow part of the floating ball mold with the steel needle 6, extruded or pressed to shape, and the steel needle 6 is drawn out to obtain the finished floating ball carrier 3 with the recess 2, the honeycomb hole and the channel space 4.

[0043] Wherein: the drift ball mold comprises a pair of hemispherical shells (see figure 2 ). The shell is provided with a convex hole 5, and the hollow part inside is provided with a steel needle 6 with a diameter of 9 mm. The shell refers to a spherical mold with a diameter of 90mm.

[0044] (4) The finished product of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com