Ecological toilet and excrement treatment integrated system

A toilet and manure technology, applied in the field of ecological toilet and manure treatment integrated system, can solve problems such as waste, not in line with the scientific development concept, and polluted water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

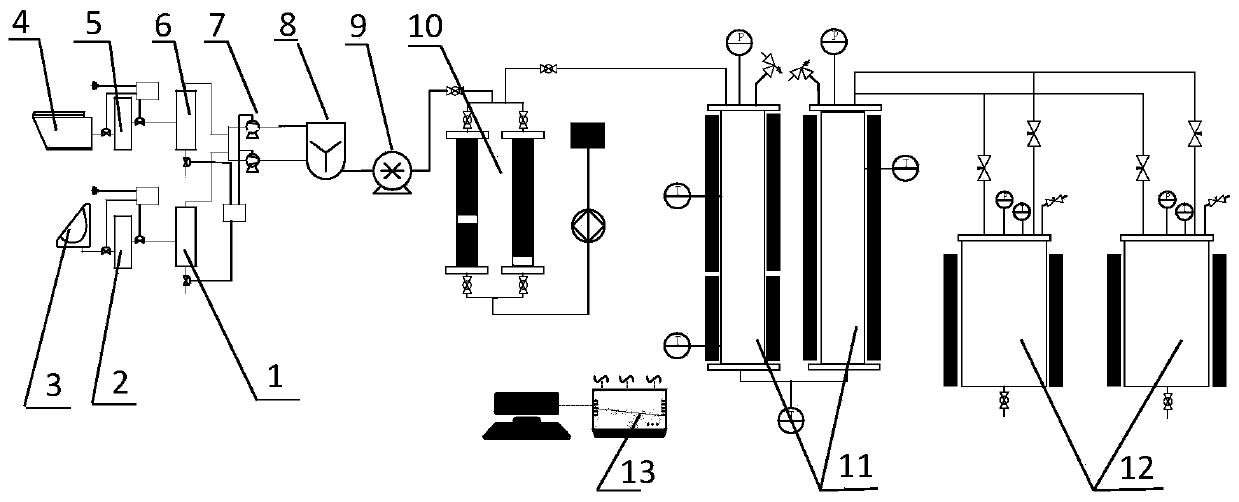

[0051] The integrated ecological toilet and manure treatment system was put in a rural area for a real-life test: first, the user presses the start button after going to the toilet to flush the feces with the driving force of negative pressure drainage, and records the number of times of toilet flushing. When the number of times of flushing the toilet is 150 times, it shows that the flow of people has reached 150 people, and the excrement has been collected in the storage tank 8, and the obtained excrement is a mixed material with a uniform concentration of 12.5%; then the screw pump 9 is used to pump the excrement to the hydraulic feed unit 10, and then pumped into the reactor unit 11 through the hydraulic feed unit 10, the feed flow rate is 50ml / min, and the reaction parameters are set by the monitoring unit 13. The pressure is 9.0MPa and the temperature is 300°C. Continuous hydrothermal treatment system After reaching a steady state, the hydraulic feed unit 10 has been conve...

Embodiment 2

[0053] The test of the back-end continuous hydrothermal treatment module of the integrated system was carried out with a mixture of human feces and corn stalks at a concentration of 15% as raw material: First, the corn stalks were mechanically crushed through 40-mesh human manure with a moisture content of 85%. Mix according to a certain ratio to obtain a mixed material with a concentration of 15%, use the screw pump 9 to pump the excrement to the hydraulic feed unit 10, and then pump it to the reactor unit 11 through the hydraulic feed unit 10, and the feed flow rate is 40ml / min, use the monitoring unit 13 to set the reaction parameters pressure 8.5MPa and temperature 290 ° C, after the continuous hydrothermal treatment system reaches a steady state, the hydraulic feeding unit 10 has been transporting materials, the reaction continues, the running time is 12 hours, and finally use the product to separate Unit 12 collects gas and liquid mixture, the gas is mainly CO 2 , the l...

Embodiment 3

[0055] The test of the integrated treatment system is carried out with simulated feces with a concentration of 20% as the raw material: firstly, 200g of the prepared simulated feces is used for toilet simulation, and after using the toilet, press the start button to flush the simulated feces with the driving force of negative pressure drainage , carry out 120 toilet simulations a day to characterize the flow scale of 120 people in the toilet; then use the storage tank 8 to collect the simulated ight soil, the obtained ight soil is a uniform concentration of 14% mixed material, and then use the screw pump 9 to pump the material sent to the hydraulic feed unit 10, and then pumped to the reactor unit 11 through the hydraulic feed unit 10, the feed flow rate is 45ml / min, and the monitoring unit 13 is used to set the reaction parameters. The pressure is 9.0MPa and the temperature is 300°C. After reaching a steady state, the hydraulic feed unit 10 has been conveying materials, the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com