A kind of yellow high-gloss glaze for ceramics and preparation method thereof

A yellow and glaze technology, applied in the field of yellow high-gloss glaze for ceramics and its preparation, can solve the problems that the surface brightness of the yellow glaze is difficult to reach an excellent level, affect the crystallization effect of niobium oxide, etc., and achieve excellent gloss, cost control, and gloss. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

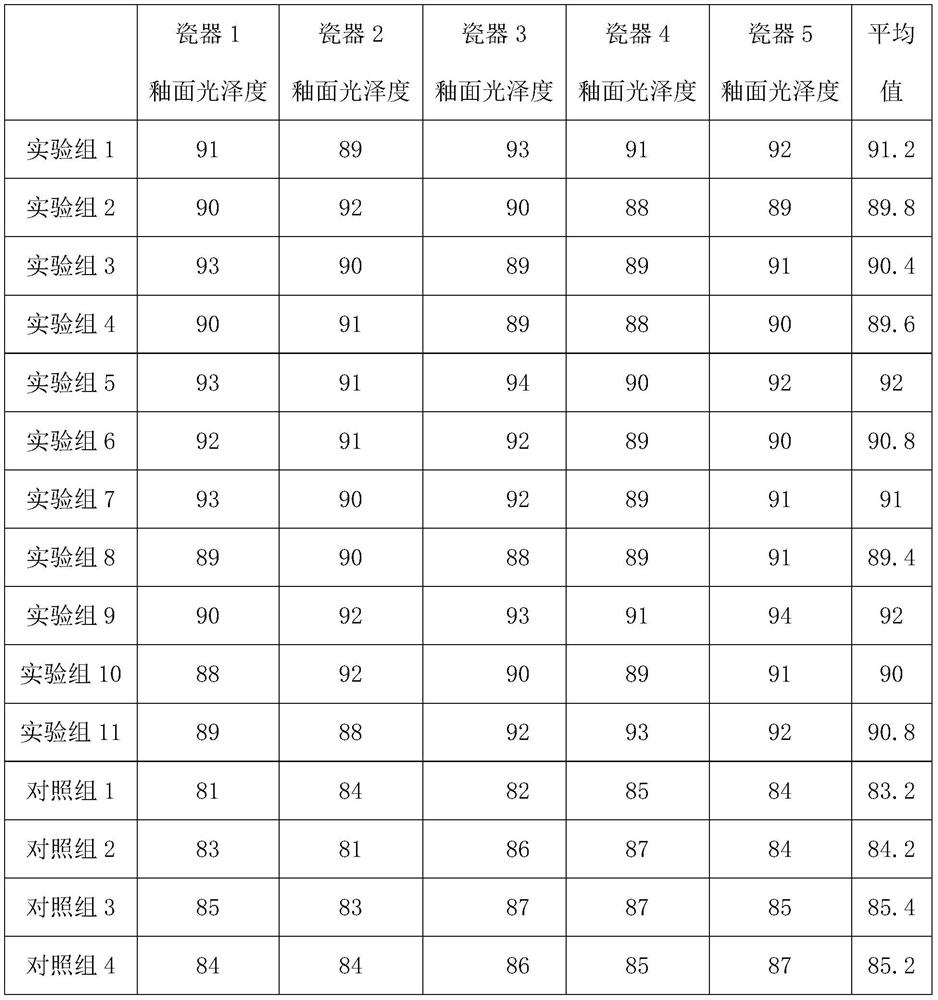

Examples

Embodiment 1

[0027] A yellow high-gloss glaze for ceramics, consisting of the following components in parts by weight: 32 parts of potassium feldspar, 18 parts of quartz, 6 parts of marble, 7 parts of kaolin, 6 parts of transparent frit, 50 parts of water, and 1 part of niobium oxide , 2 parts of yellow pigment, 1 part of barium chromate.

[0028] A preparation method of yellow high-gloss glaze for ceramics, comprising the following steps:

[0029] Step 1. Mix 32 parts of potassium feldspar, 18 parts of quartz, 6 parts of marble, 7 parts of kaolin, 6 parts of transparent frit, and 50 parts of water, and then ball mill it into glaze slurry. The ball milling time is 16 hours, and the magnetic field strength of the glaze slurry is The 10,000 Gauss iron remover removes iron three times, and the glaze slurry passes through a 325-mesh standard sieve;

[0030] Step 2, mix 1 part of niobium oxide, 2 parts of yellow pigment, and 1 part of barium chromate evenly and ball-mill them into a powder, an...

Embodiment 2

[0033] A yellow high-gloss glaze for ceramics, consisting of the following components by weight: 48 parts of albite, 38 parts of quartz, 13 parts of marble, 14 parts of kaolin, 10 parts of transparent frit, 70 parts of water, and 4 parts of niobium oxide , 8 parts of yellow pigment, 4 parts of barium chromate.

[0034] A preparation method of yellow high-gloss glaze for ceramics, comprising the following steps:

[0035] Step 1: Mix 48 parts of albite feldspar, 38 parts of quartz, 13 parts of marble, 14 parts of kaolin, 10 parts of transparent frit, and 70 parts of water, and then ball mill it into a glaze slurry. The ball milling time is 19 hours. The 10,000 gauss iron remover removes iron 5 times, and the glaze slurry passes through a 380-mesh standard sieve;

[0036] In step 2, 4 parts of niobium oxide, 8 parts of yellow pigment, and 4 parts of barium chromate are mixed evenly and ball-milled into a powder, and the powder is passed through a 380-mesh standard sieve;

[003...

Embodiment 3

[0039] A yellow high-gloss glaze for ceramics, consisting of the following components in parts by weight: 36 parts of albite, 25 parts of quartz, 8 parts of marble, 9 parts of kaolin, 7 parts of transparent frit, 56 parts of water, and 2 parts of niobium oxide , 4 parts of yellow pigment, 2 parts of barium chromate.

[0040] A preparation method of yellow high-gloss glaze for ceramics, comprising the following steps:

[0041] Step 1: Mix 36 parts of albite feldspar, 25 parts of quartz, 8 parts of marble, 9 parts of kaolin, 7 parts of transparent frit, and 56 parts of water, and ball mill it into glaze slurry. The 10,000 gauss iron remover removes iron 4 times, and the glaze slurry passes through a 325-mesh standard sieve;

[0042] In step 2, 2 parts of niobium oxide, 4 parts of yellow pigment, and 2 parts of barium chromate are mixed evenly and ball-milled into a powder, and the powder is passed through a 325-mesh standard sieve;

[0043] Step 3, uniformly mixing the glaze s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com