Lightweight wear-resistant automobile side window glass and preparation method thereof

A technology for automotive side and window glass, applied in windshields, windows, vehicle parts, etc., can solve the problems of poor wear resistance, weather resistance and hydrophobicity, inability to waterproof and anti-fog, and affect the use performance, etc., to achieve weather resistance. Good property and hydrophobicity, improve adhesion, highlight the effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

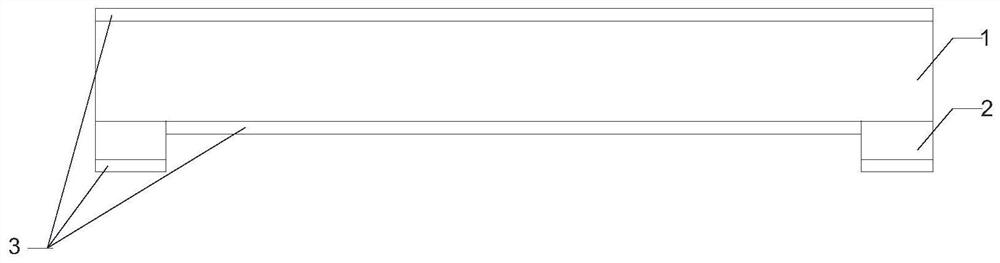

[0034] Such as figure 1 Shown, a kind of lightweight wear-resistant automobile side window glass, comprises the polycarbonate base layer 1 that thickness is 5mm, is provided with the PC / ABS black border layer 2 that thickness is 2.5mm around one side of polycarbonate base layer, polycarbonate The surface on both sides of the ester base layer and the surface of the PC / ABS black edge layer are coated with a surface coating 3 with a thickness of 15 μm.

[0035] The preparation method of the coating used for the surface coating is:

[0036] (A) Nano-SiO 2 Dispersed in ethanol, added with nano-SiO 2 The ratio is 9mL: 5g of γ-aminopropyltriethoxysilane and 2 drops of triethylamine, stirred and reacted for 6h and then centrifuged, washed the product twice with ethanol, acetone and tetrahydrofuran in sequence, and then dispersed the product in tetrahydrofuran, Joined with nano-SiO 2 Glutaric anhydride with a mass ratio of 2.5:1 was centrifuged after stirring for 6 hours, washed re...

Embodiment 2

[0046] A light wear-resistant automobile side window glass, comprising a polycarbonate base layer with a thickness of 3mm, a PC / ABS black edge layer with a thickness of 2mm is provided around one side of the polycarbonate base layer, and the two sides of the polycarbonate base layer And the PC / ABS black edge layer is coated with a surface coating with a thickness of 10 μm.

[0047] The preparation method of the coating used for the surface coating is:

[0048] (A) Nano-SiO 2 Dispersed in ethanol, added with nano-SiO 2 The ratio is 8mL: 5g of γ-aminopropyltriethoxysilane and 1 drop of triethylamine, stirred and reacted for 5h and then centrifuged. After washing the product twice with ethanol, acetone and tetrahydrofuran, the product was dispersed in tetrahydrofuran. Joined with nano-SiO 2 Glutaric anhydride with a mass ratio of 2:1 was centrifuged after stirring for 5 hours, washed repeatedly with 0.1mol / L NaCl solution and dried to obtain carboxylated nano-SiO 2 ;

[0049...

Embodiment 3

[0058] A light wear-resistant automobile side window glass, comprising a polycarbonate base layer with a thickness of 8mm, a PC / ABS black border layer with a thickness of 3mm is provided around one side of the polycarbonate base layer, and the two sides of the polycarbonate base layer And the PC / ABS black edge layer is coated with a surface coating with a thickness of 20 μm.

[0059] The preparation method of the coating used for the surface coating is:

[0060] (A) Nano-SiO 2 Dispersed in ethanol, added with nano-SiO 2 The ratio is 10mL: 5g of γ-aminopropyltriethoxysilane and 3 drops of triethylamine, stirred and reacted for 8h and then centrifuged. After washing the product twice with ethanol, acetone and tetrahydrofuran, the product was dispersed in tetrahydrofuran. Joined with nano-SiO 2 Glutaric anhydride with a mass ratio of 3:1 was centrifuged after stirring for 8 hours, washed repeatedly with 0.1mol / L NaCl solution and dried to obtain carboxylated nano-SiO 2 ;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com