Lubricating oil composition and preparation method thereof

A technology of lubricating oil composition and mineral oil, applied in the field of lubricating oil, can solve the problems of inability to dissipate heat in time, slow running speed, inconvenient oil change operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

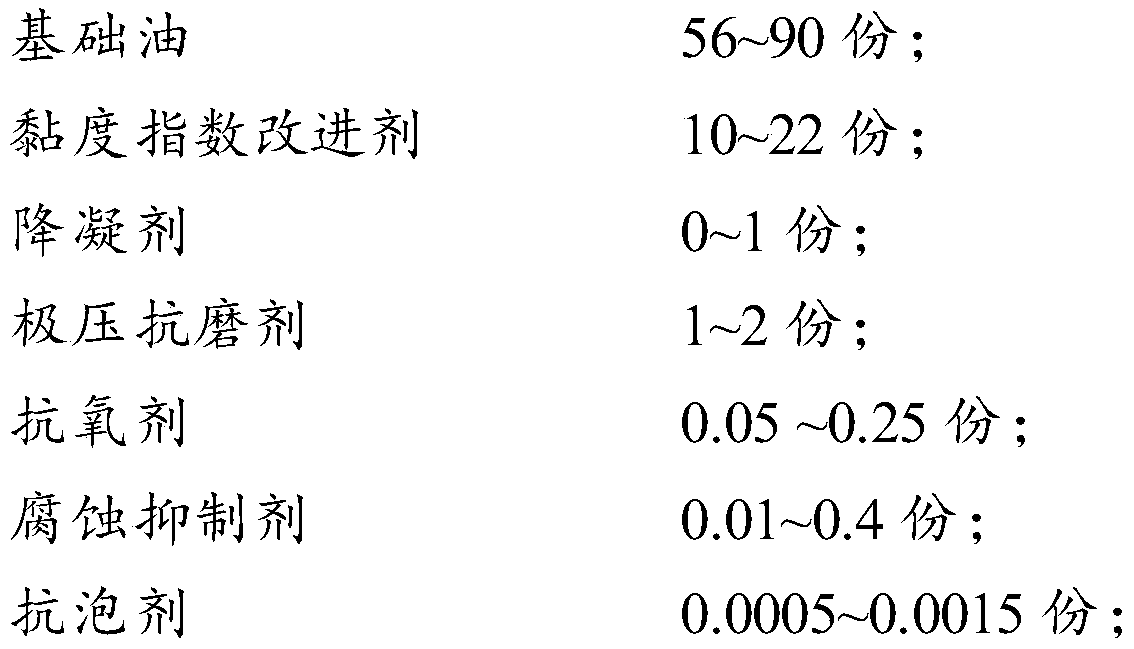

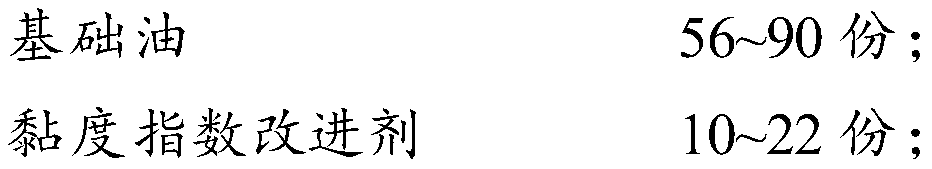

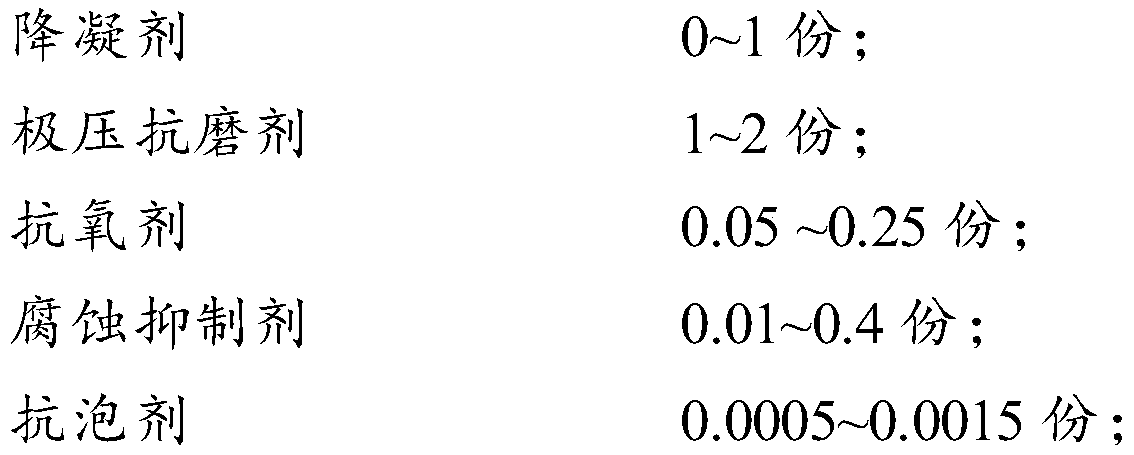

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a method for preparing the lubricating oil composition described above, comprising the following steps:

[0056] A) Stir the base oil at a vacuum degree of -0.090 to -0.095MPa and a temperature of 75 to 85°C to obtain a dehydrated base oil;

[0057] B) Mix the dehydrated base oil with the viscosity index improver at 60-70°C to obtain a hot mixture; or cool down the dehydrated base oil and mix it with the dilution of the viscosity index improver at 60-70°C , to obtain a hot mixture;

[0058] C) stirring and mixing the hot mixed liquid with antioxidant, extreme pressure antiwear agent, corrosion inhibitor and antifoaming agent at 55-65° C., and cooling to obtain a lubricating oil composition.

[0059] In the preparation method of the lubricating oil composition provided by the present invention, the raw material components and proportions used are the same as above, and will not be repeated here.

[0060] In the invention, the base oi...

Embodiment 1

[0080] Weigh medium viscosity polyalphaolefin oil PAO20 (40°C kinematic viscosity 190mm 2 / s) 5.0kg and 120BS bright stock 76.56kg, pour the two into the container, stir at -0.095MPa vacuum degree, 85℃ temperature for 1h for dehydration treatment. The temperature was lowered to 70° C., and 16.5 kg of polyisobutylene was added dropwise (dropping rate: 250 L / h) with stirring to obtain a hot mixed liquid. Remove the vacuum, lower the temperature to 65°C, add 0.5kg of polymethyl methacrylate, 0.9kg of sulfurized isobutylene, 0.135kg of C13 tertiary alkylamine, 0.072kg of C8 alkyl phosphite, 0.036kg of diisooctyl phosphate, monophosphate Isooctyl ester 0.036kg, C18 alkanol borate 0.036kg, C18 enamine 0.0315kg, finally add 0.01kg of 5000# methyl silicone oil dilution (the quality of 5000# methyl silicone oil in the 5000# methyl silicone oil dilution is 0.001 kg, 5000# methyl silicone oil and kerosene are mixed uniformly at a mass ratio of 1:9 to obtain 5000# methyl silicone oil dilu...

Embodiment 2

[0082] Weigh medium viscosity polyalphaolefin oil PAO40 (40°C kinematic viscosity 400mm 2 / s) 15kg and 70.06kg of 150BS bright stock, pour the two into the container, stir at -0.090MPa vacuum, 75°C for 0.5h for dehydration. The temperature was lowered to 60° C., and 13 kg of polyisobutylene was added dropwise (dropping rate: 200 L / h) with stirring to obtain a hot mixed liquid. Remove the vacuum, lower the temperature to 55°C, add 0.5kg of polymethyl methacrylate, 0.9kg of sulfurized isobutylene, 0.135kg of C13 tertiary alkylamine, 0.072kg of C8 alkyl phosphite, 0.036kg of diisooctyl phosphate, monophosphate Isooctyl ester 0.036kg, C18 alkanol borate 0.036kg, C18 enamine 0.0315kg, finally add 0.01kg of 5000# methyl silicone oil dilution (the quality of 5000# methyl silicone oil in the 5000# methyl silicone oil dilution is 0.001 kg, 5000# methyl silicone oil and kerosene are mixed uniformly at a mass ratio of 1:9 to obtain 5000# methyl silicone oil dilution). Stir at a constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com