High-fill-power down preparation method

A technology of bulkiness and down, which is applied in the field of down, which can solve the problems of high dust content of down, poor dust removal effect, down damage, etc., and achieve the effect of good antibacterial function, enhanced mobility, and less damage to down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

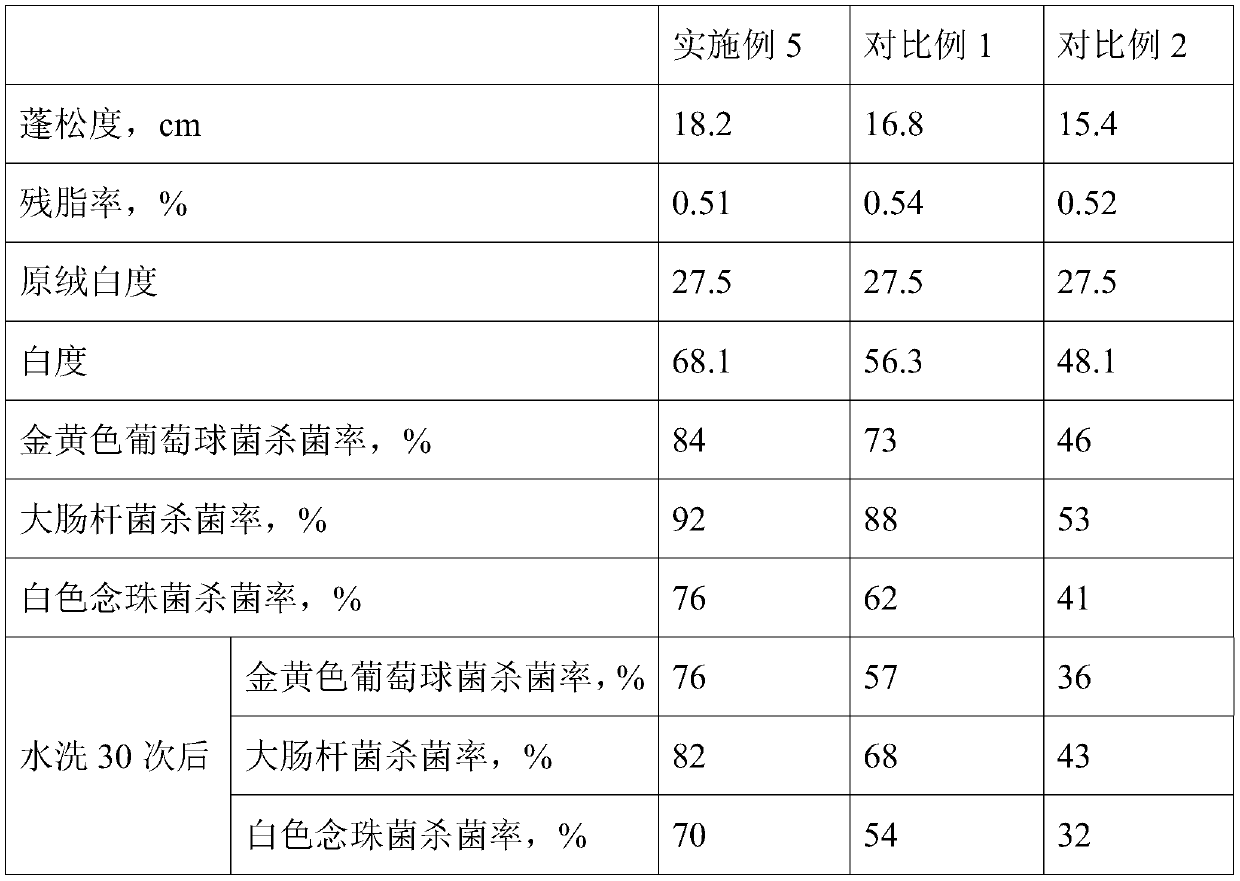

Examples

Embodiment 1

[0025] A preparation method of high bulkiness down, comprising the steps of:

[0026] S1. Wash the raw down for 20 minutes, dehydrate it, and dry it at 60°C to remove residual dust and sand to obtain prefabricated down;

[0027] S2. Mix 10kg humic acid and 80kg potassium hydroxide solution with a concentration of 0.5mol / L, heat up to 80°C and stir for 15min, add 0.2kg epoxy soybean oil and 1kg graphene, and shake for 20 days at a speed of 60r / min , add 6kg of sweet potato protein powder, adjust the pH value of the system to 8.8-9.4 with a concentration of 2wt% sodium carbonate solution, add 2kg of aminopropyl-blocked polycyanopropylmethylsiloxane and continue to stir for 2h at a stirring speed of 1600r / min , and then microwave treatment for 2 minutes, the microwave treatment power is 420W, the water is distilled off, and the prefabricated material is obtained by freeze-drying;

[0028] S3. Add 0.5kg of detergent to 55kg of prefabricated down for fine washing for 10 minutes, t...

Embodiment 2

[0031] A preparation method of high bulkiness down, comprising the steps of:

[0032] S1. Wash the raw down for 30 minutes, dehydrate it, and dry it at 50°C to remove residual dust and sand to obtain prefabricated down;

[0033] S2. Mix 20kg humic acid and 40kg potassium hydroxide solution with a concentration of 0.9mol / L, heat up to 70°C and stir for 26min, add 0.1kg epoxy soybean oil and 2kg graphene, and shake for 10 days at a shaking speed of 80r / min , add 3kg of sweet potato protein powder, adjust the pH value of the system to 8.8-9.4 with a concentration of 4wt% sodium carbonate solution, add 1kg of aminopropyl-blocked polycyanopropylmethylsiloxane and continue to stir for 3h at a stirring speed of 1200r / min , then microwave treatment for 5 minutes, the microwave treatment power is 400W, the water is distilled off, and the prefabricated material is obtained by freeze-drying;

[0034] S3, adding 1.5kg of detergent to 45kg of prefabricated down and fine washing for 20min,...

Embodiment 3

[0037] A preparation method of high bulkiness down, comprising the steps of:

[0038] S1. Wash the raw down for 22 minutes, dehydrate it, and dry it at 58°C to remove residual dust and sand to obtain prefabricated down;

[0039] S2. Mix 13kg humic acid and 70kg potassium hydroxide solution with a concentration of 0.6mol / L, heat up to 77°C and stir for 18min, add 0.18kg epoxy soybean oil and 1.3kg graphene, and shake for 18 days at a speed of 65r / L min, add 5kg of sweet potato protein powder, adjust the pH value of the system to 8.8-9.4 with a concentration of 2.5wt% sodium carbonate solution, add 1.7kg of aminopropyl-blocked polycyanopropylmethylsiloxane and continue stirring for 2.2h, the stirring speed 1500r / min, then microwave treatment for 3min, the microwave treatment power is 415W, distilled to remove water, freeze-dried to obtain the prefabricated material;

[0040] S3, adding 0.8kg of detergent to 52kg of prefabricated down for fine washing for 12 minutes, then rinsin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com