Ion adsorbent and preparation method and application thereof

A technology of ion adsorbent and calcium ion, which is applied in the field of ion adsorbent and its preparation, to achieve the effect of stable performance, less steps and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

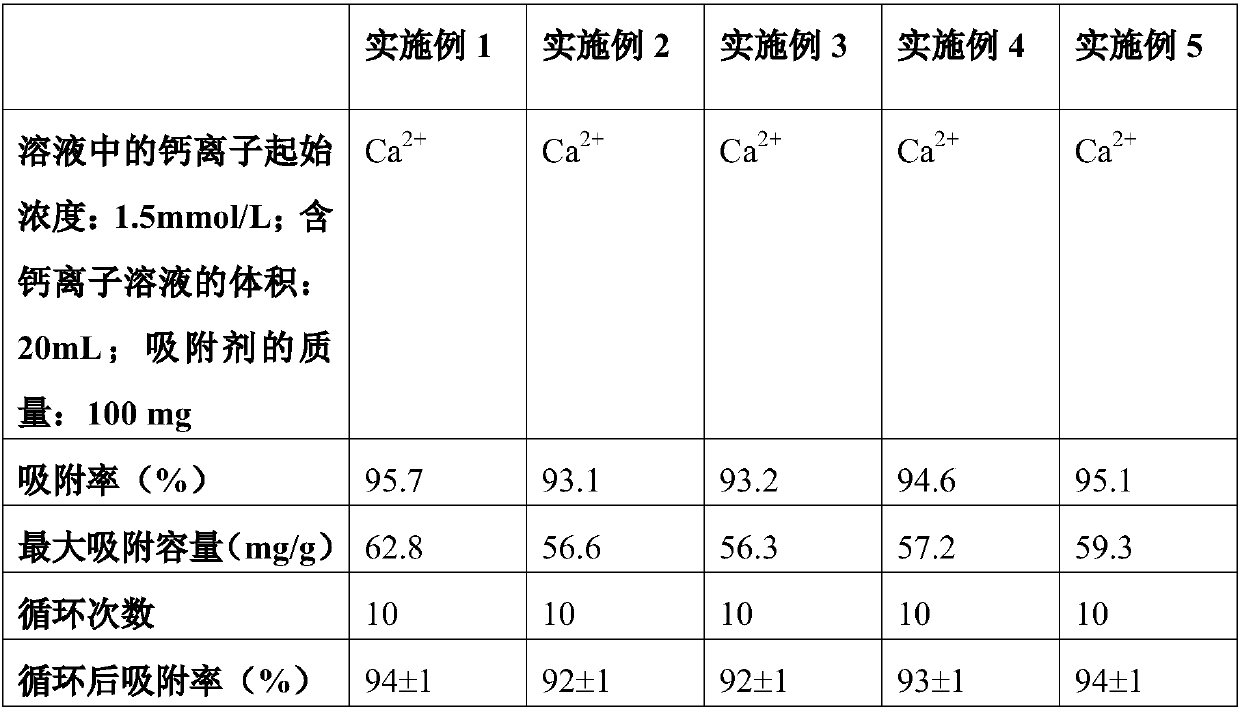

Embodiment 1

[0062] Preparation of ionic adsorbent:

[0063] (1) Weigh 1.0g of sodium alginate and 1.0g of citric acid and dissolve them in 50mL of water, and add 0.25g of 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride and 0.15g of N-hydroxysuccinimide was activated for 3 hours, then 9.0g of ethylenediamine was added, and reacted at 25°C for 2 hours to obtain solution I;

[0064] (2) Under stirring conditions at 25°C, drop solution I into a 0.2mol / L calcium nitrate solution, and continue stirring for 20 minutes after dropping; filter, wash the solid product with deionized water, and freeze-dry in a vacuum , to prepare ion adsorbents.

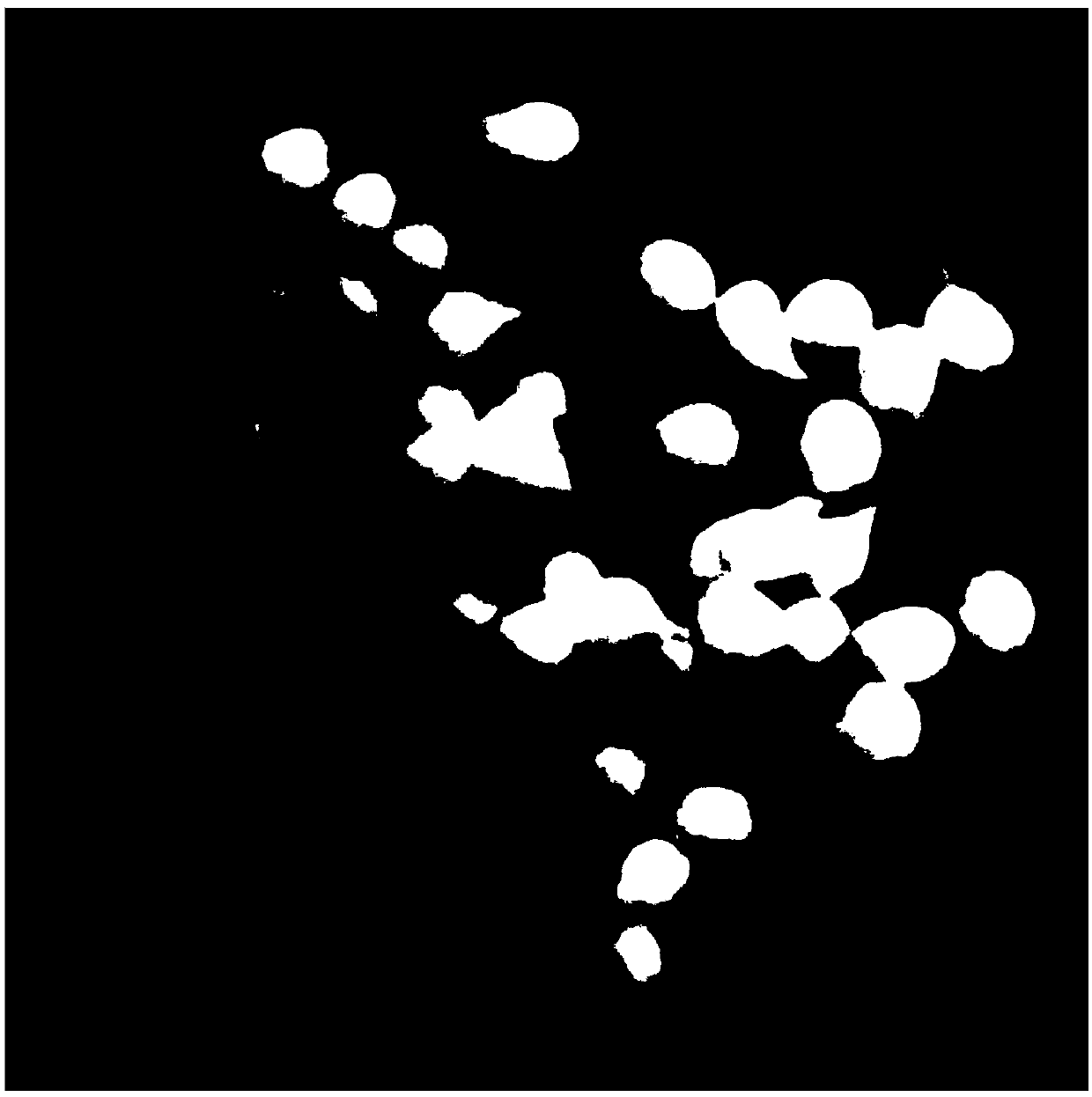

[0065] The morphology photo of the ion adsorbent is as follows: figure 1 shown.

Embodiment 2

[0067] Preparation of ionic adsorbent:

[0068] (1) Weigh 1.0g potassium alginate and 1.0g citric acid and dissolve in 50mL water, under stirring condition, add 0.25g 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride and 0.15g of N-hydroxysuccinimide was activated for 3 hours, then 9.0g of ethylenediamine was added, and reacted at 25°C for 2 hours to obtain solution I;

[0069] (2) Under stirring conditions at 25°C, drop solution I into a 0.2mol / L calcium nitrate solution, and continue stirring for 20 minutes after dropping; filter, wash the solid product with deionized water, and freeze-dry in a vacuum , to prepare ion adsorbents.

[0070] The difference between Example 2 and Example 1 is that sodium alginate is replaced by potassium alginate.

Embodiment 3

[0072] Preparation of ionic adsorbent:

[0073] (1) Weigh 1.0g of alginic acid and 1.0g of citric acid and dissolve them in 50mL of water, and add 0.25g of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride and 0.15 g N-hydroxysuccinimide was activated for 3 hours, then 9.0 g of ethylenediamine was added, and reacted for 2 hours at 25°C to obtain solution I;

[0074] (2) Under stirring conditions at 25°C, drop solution I into a 0.2mol / L calcium nitrate solution, and continue stirring for 20 minutes after dropping; filter, wash the solid product with deionized water, and freeze-dry in a vacuum , to prepare ion adsorbents.

[0075] The difference between Example 3 and Example 1 is that sodium alginate is replaced by alginic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com