High-temperature-resistant dopamine-coated barium titanate/polyimide (BT@PDA/PI) dielectric nano composite film

A polydopamine-coated barium titanate and nanocomposite technology, which is applied in the fields of ceramic particles/polyimide nanocomposite film and its preparation, high temperature resistant polyimide dielectric nanocomposite material and its preparation, can solve the problem of compounding Problems such as poor temperature resistance of the film, to achieve the effect of increasing the dielectric constant, simple equipment maintenance and cleaning, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0026] (1) Preparation of BT@PDA nanoparticles: at room temperature, mix 3 g of BT nanoparticles (product of Shanghai Aladdin Biochemical Technology Co., Ltd., purity 99.9%) and 100 mL of 0.1 mol / L hydroxymethylaminomethane buffer (Tris) (product of Beijing Chemical Plant, purity 99%) and 200 mL of deionized water, and magnetically stirred for 20 min; add 100 mL of absolute ethanol and 1 g of dopamine hydrochloride solution (product of Beijing Chemical Plant, purity 98%) to the system ), continue stirring and coating for 6 h, until the system turns dark brown; filter, and wash the obtained product with 1:1 ethanol aqueous solution; centrifuge and wash after standing, and keep the lower sediment; repeat the centrifugation process 5 times, until the system The pH value was close to 7, and finally the obtained product was dried in an oven at 60 °C for 8 h to obtain BT@PDA nanoparticles.

[0027] (2) Synthesis of polyamic acid (PAA): PAA solution was prepared by in-situ polymeriza...

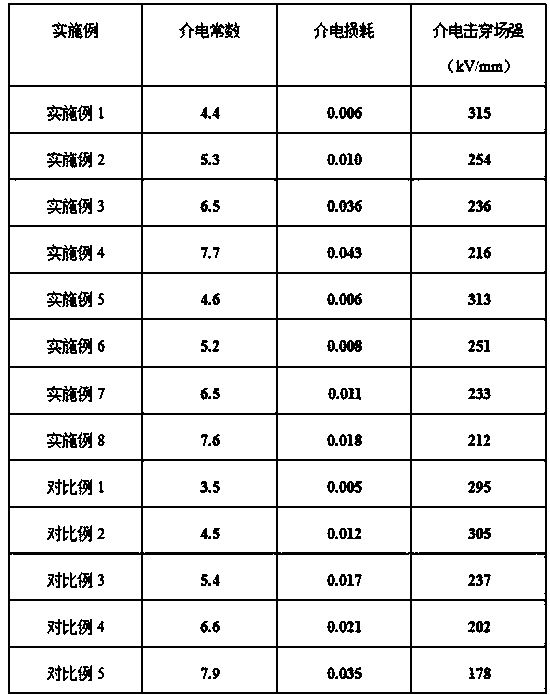

Embodiment 5~8

[0030] Examples 5-8: When preparing BT@PDA nanoparticles, the stirring coating time was extended to 10h, and other process conditions were the same.

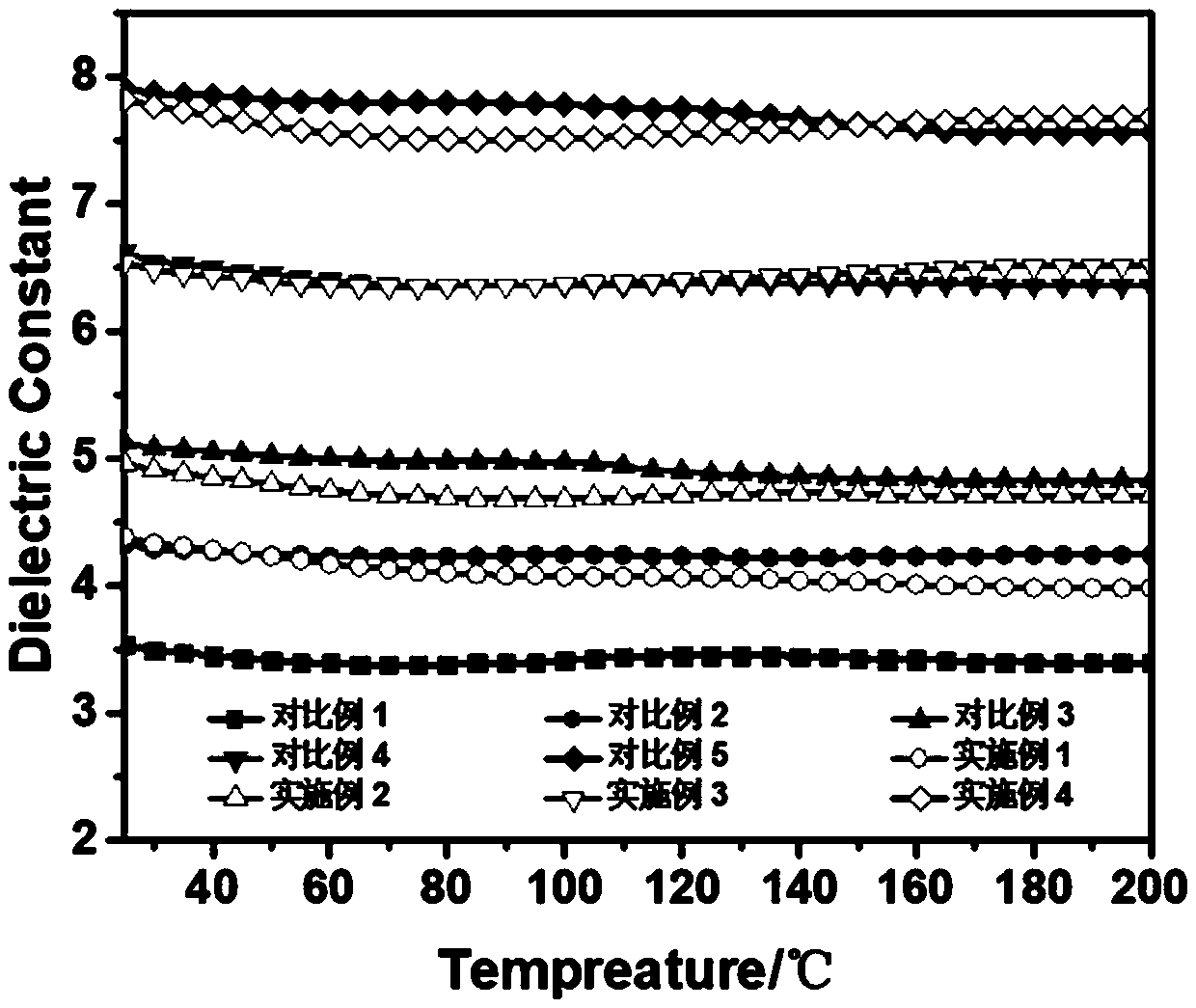

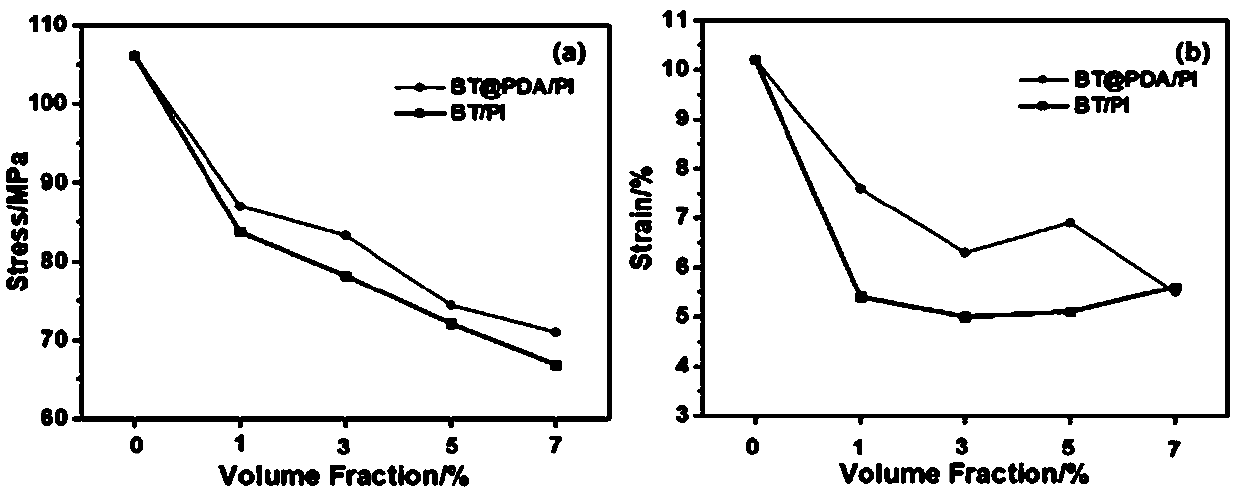

[0031] Comparative examples 1-5, using the same process conditions, first blended BT nanoparticles and PAA, and then prepared BT / PI composite film, the filler content was 0, 1vol%, 3vol%, 5vol% and 7vol%, respectively, as a comparison Proportion. Concrete formulation is as shown in Table 1:

[0032] Table 1 embodiment 1 ~ 8 and comparative example 1 ~ 5 formula table

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com