Safe edible ink for food and drug surface printing and preparation method thereof

A surface printing and pharmaceutical technology, applied in the formulation and production process of safe edible inks, can solve the problems of lack of anti-corrosion function, ink food safety impact, edible ink odor impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

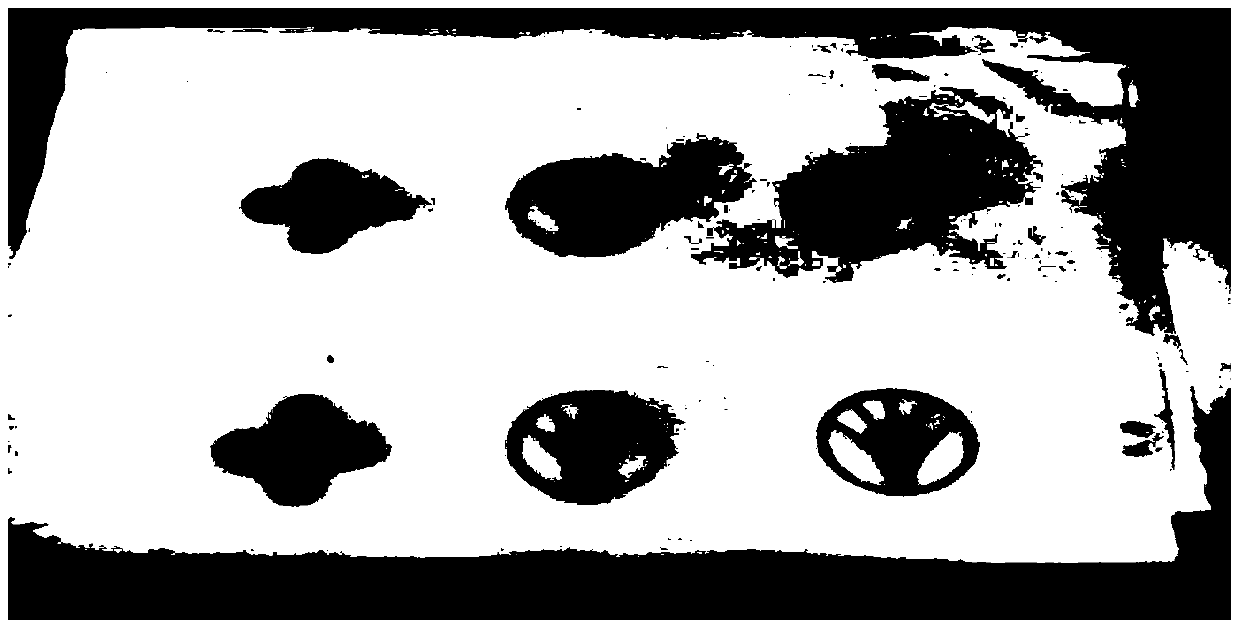

Image

Examples

Embodiment 1

[0027] S1. Take 100 parts of starch, add 40 parts of glycerin to grind and plasticize; then add 300 parts of water, stir and gelatinize at 100 degrees Celsius for 30 minutes to obtain A solution;

[0028] S2. Take 30 parts of vegetable gum, add 500 parts of water, stir and dissolve at a temperature of 90 degrees Celsius for 60 minutes, and obtain solution B;

[0029] S3. Mix the solution A and solution B obtained above and stir evenly at a stirring speed of 500 rpm, then add 37 parts of color paste in turn at a temperature of 40 degrees Celsius and a stirring speed of 700 rpm to make a homemade toughening agent 7 parts, 8 parts of self-made preservative solution, 10 parts of dispersant polyethylene glycol, 10 parts of cross-linking agent calcium chloride, 7.5 parts of adipic acid, stir until completely evenly mixed to make edible ink.

[0030] Wherein, the color paste is extracted from purple cabbage, and the specific steps include: distilling and extracting, using a rotary ev...

Embodiment 2

[0040] S1. Take 100 parts of starch, add 30 parts of glycerin to grind and plasticize; then add 300 parts of water, stir and gelatinize at 100 degrees Celsius for 30 minutes, and obtain A solution;

[0041] S2. Take 40 parts of vegetable gum, add 300 parts of water, stir and dissolve at a temperature of 90 degrees Celsius for 60 minutes, and obtain solution B;

[0042] S3. Mix the solution A and solution B obtained above and stir evenly at a stirring speed of 500 rpm, then add 47 parts of color paste in turn at a temperature of 40 degrees Celsius and a stirring speed of 700 rpm to make a homemade toughening agent 10 parts, 12 parts of self-made preservative solution, 7 parts of dispersant polyethylene glycol, 10 parts of cross-linking agent calcium chloride, 10 parts of adipic acid, stir until completely evenly mixed to make edible ink.

[0043]Wherein, the color paste is extracted from purple cabbage, and the specific steps include: distilling and extracting, using a rotary e...

Embodiment 3

[0053] S1. Take 100 parts of starch, add 60 parts of glycerin to grind and plasticize; then add 600 parts of water, stir and gelatinize at 100 degrees Celsius for 30 minutes, and obtain A solution;

[0054] S2. Take 35 parts of vegetable gum, add 400 parts of water, stir and dissolve at a temperature of 90 degrees Celsius for 60 minutes, and obtain solution B;

[0055] S3. Mix the solution A and solution B obtained above and stir evenly at a stirring speed of 500 rpm, then add 47 parts of color paste in turn at a temperature of 40 degrees Celsius and a stirring speed of 700 rpm to make a homemade toughening agent 8 parts, 10 parts of self-made preservative solution, 8 parts of dispersant polyethylene glycol, 10 parts of cross-linking agent calcium chloride, 7 parts of adipic acid, stir until completely evenly mixed to make edible ink.

[0056] Wherein, the color paste is extracted from purple cabbage, and the specific steps include: distilling and extracting, using a rotary ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com