Annular cowshed

A ring-shaped, cowshed technology, applied in animal houses, applications, animal husbandry, etc., can solve the problems of backward feeding mode, unclean cattle body, limited activity space, etc., so as to increase the effective use area and avoid polluting surrounding areas. environment, the effect of improving the living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

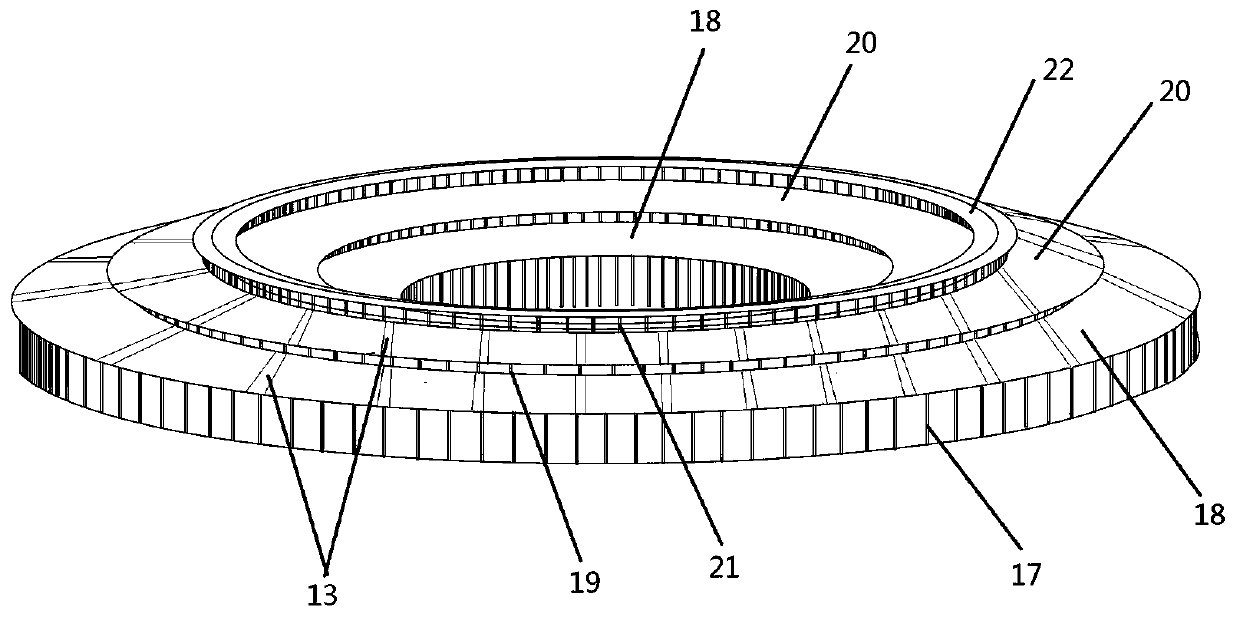

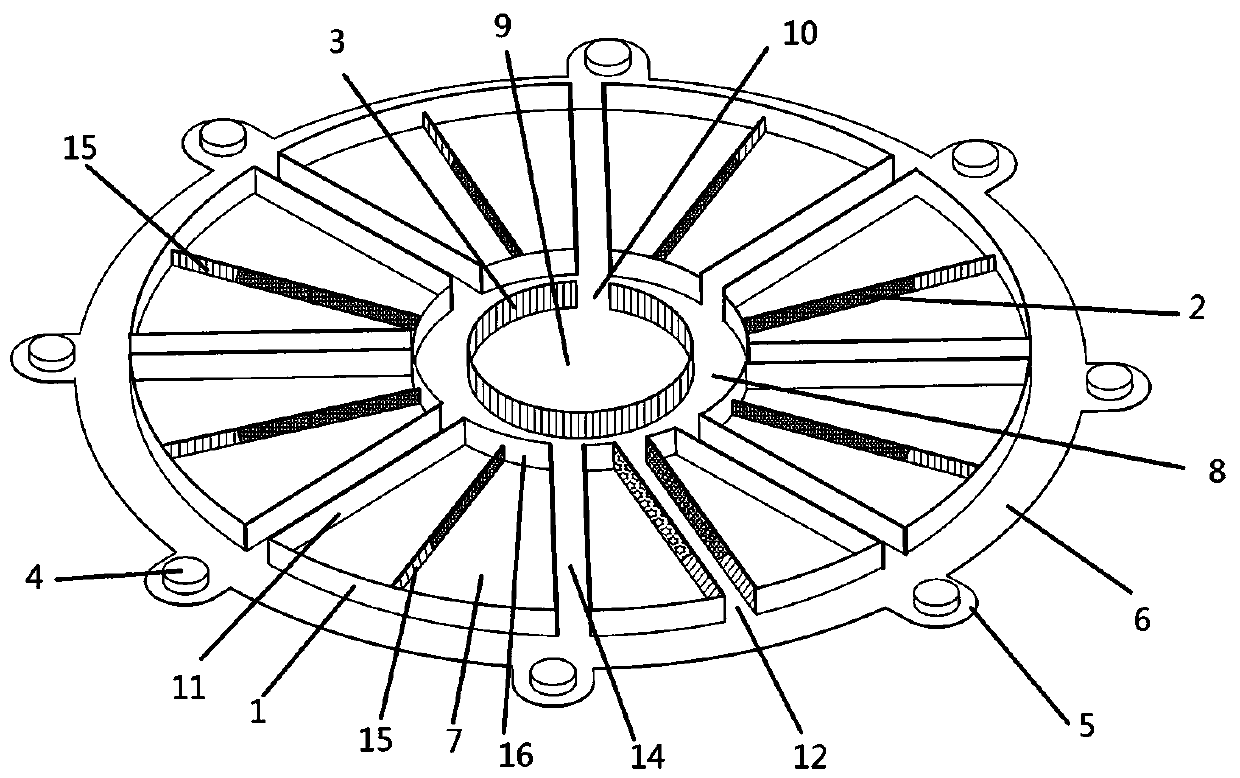

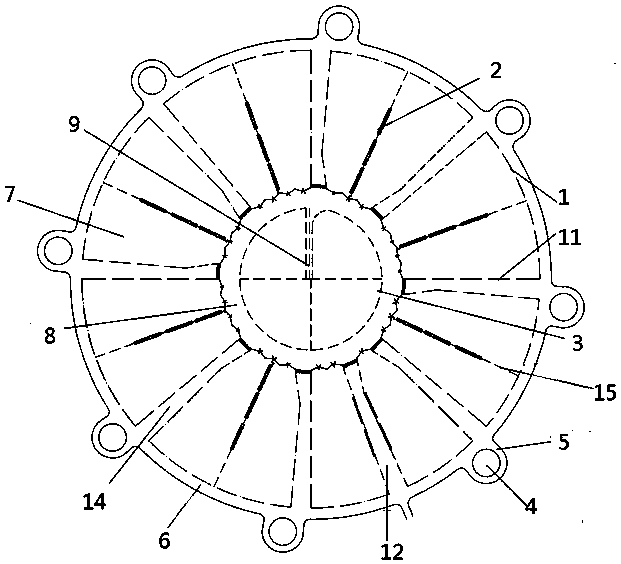

[0014] Example 1, such as Figure 1-3 As shown, a ring-shaped barn includes a ring-shaped barn body and feeding facilities and equipment arranged in the body. The ring-shaped cowshed body adopts a three-story bell tower double-slope building structure, including structural columns 17, the bottom bell tower roof 18, the middle bell tower roof 20, the top bell tower roof 22, the lower air vent structural column 19, and the upper air vent structural column 21 . All roofs are arranged symmetrically with double slopes along the ridge. The upper part of the structural column 17 is provided with a bottom floor bell tower roof 18, an intermediate floor bell tower roof 20, and a top floor bell tower roof 22, and a lower floor vent structural column 19 is arranged between the bottom floor bell tower roof 18 and the middle floor bell tower house 20, and the middle floor bell tower roof 20 is connected to the middle floor bell tower roof 20. The top-floor bell tower roof 22 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com