Cooperative disposal method of hazardous waste incineration residues and solid wastes, ceramsite and application of ceramsite

A technology for solid waste and hazardous waste, applied in the field of resources and environment, can solve the problems of limited development of ceramsite, limited shale and clay resources, etc., achieve significant economic and environmental benefits, reduce the burden on the ecological environment, and save landfill land. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

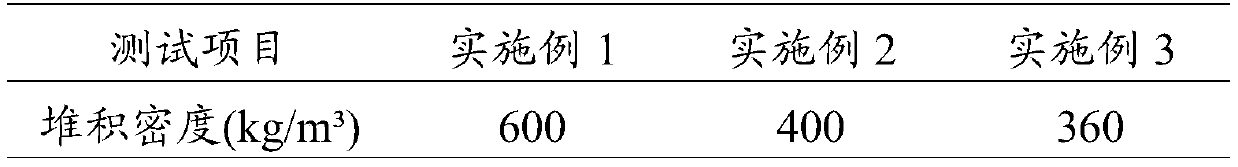

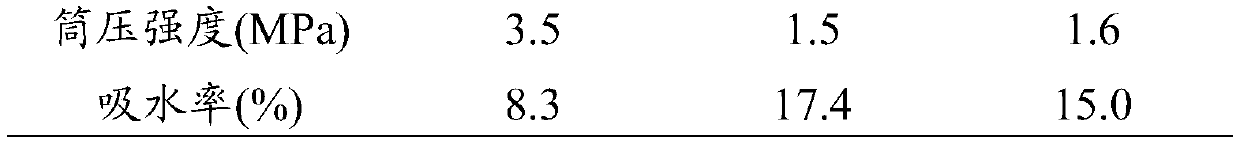

Embodiment 1

[0041] After testing, the hazardous waste incineration residue includes the following components in mass percentage: SiO 2 35wt%, total heavy metal (Pb) 30ppm, CaO 25wt%, Al 2 o 3 32wt%, 3wt% organic matter and the remainder impurities;

[0042] Hazardous waste incineration fly ash includes the following components in mass percentage: activated carbon 30wt% and calcium hydroxide 70wt%;

[0043] Fly ash includes the following components in mass percentage: SiO 2 70wt%, CaO 12wt%, Al 2 o 3 16wt% and balance impurities;

[0044] Mix 1000kg of hazardous waste incineration residue, 50kg of hazardous waste incineration fly ash and 400kg of fly ash, and transport them to granulation equipment for granulation to obtain granular materials, wherein the particle size of the granular materials is 15-20mm;

[0045] Transport the granular material to the rotary drying equipment, and dry it at 150°C for 20 minutes, and the moisture content of the obtained dried material is 3%;

[...

Embodiment 2

[0049] Hazardous waste incineration residues include the following components in mass percentages: SiO 2 35wt%, total heavy metal (Pb) 30ppm, CaO 25wt%, Al 2 o 3 32wt%, 3wt% organic matter and the remainder impurities;

[0050] Sludge includes the following components in mass percentage: SiO 2 25wt%, FeO 5wt%, Al 2 o 3 11wt%, organic matter 8wt% and balance water;

[0051] Mix 1000kg of hazardous waste incineration residue and 2000kg of sludge evenly, transport them to granulation equipment for granulation, and obtain granular materials, wherein the particle size of the granular materials is 20-25mm;

[0052] Transport the granular material to the rotary drying equipment, and dry it at 250°C for 15 minutes, and the moisture content of the obtained dried material is 1%;

[0053] Transport the dried material to a calciner, and calcinate at 1150°C for 20 minutes. The hot tail gas generated by the calcining is used to dry the granular material, and the tail gas generated...

Embodiment 3

[0056] Hazardous waste incineration residues include the following components in mass percentages: SiO 2 38wt%, total heavy metal (Pb) 40ppm, CaO 26wt%, Al 2 o 3 30wt%, 2wt% organic matter and the remainder impurities;

[0057] Oil sludge sand includes the following components in mass percentage: SiO 2 38wt%, FeO 2wt%, Al 2 o 3 10wt%, CaO 12wt%, organic matter 7wt% and balance water;

[0058] Mix 1000kg of hazardous waste incineration residue and 2000kg of oil sludge evenly, and transport them to granulation equipment for granulation to obtain granular materials, wherein the particle size of the granular materials is 10-15mm;

[0059] Transport the granular material to the rotary drying equipment, and dry it at 280°C for 10 minutes, and the moisture content of the obtained dried material is 2%;

[0060] Transport the dried material to a calciner, and calcinate at 1150°C for 20 minutes. The hot tail gas generated by the calcining is used to dry the granular material, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com