A kind of non-sintered garbage tailings brick and its preparation process

A non-sintering and garbage technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of waste of energy and resources, achieve low energy consumption, protect the ecological environment, and protect life and health Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

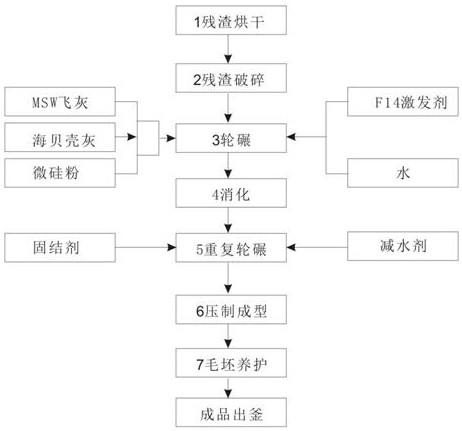

Image

Examples

Embodiment 1

[0056] A preparation process for non-sintered garbage tailings bricks, comprising the following steps:

[0057] 1) Dry the incineration residue to a moisture content of 3-8%;

[0058] 2) Crushing the drying and incineration residue until the particle size is no more than 3mm, which becomes a natural gradation;

[0059] 3) Wheel mill mixing process: 82.9 parts by weight of incineration residue, 4 parts by weight of MSW fly ash, 8 parts by weight of sea shell ash, 4 parts by weight of microsilica, 1.1 parts by weight of F14 activator, 10 parts by weight Input the water into the XLH-800 planetary wheel mill mixer for mixing and grinding, and the grinding time is 6min to form a mixture;

[0060] 4) Mixed material digestion process: input the mixed material into the continuous digestion bin for continuous digestion, the temperature in the bin is kept at 60°C, and the digestion time is 3 hours to become digested material;

[0061] 5) Digestive material mixing and repeated wheel mi...

Embodiment 2

[0065] A preparation process of non-sintered garbage tailings brick:

[0066] 1) Same as embodiment 1 process step 1);

[0067] 2) Same as embodiment 1 process step 2);

[0068] 3) Wheel grinding mixing process: 79.2 parts by weight of incineration residue, 5 parts by weight of MSW fly ash, 10 parts by weight of sea shell ash, 5 parts by weight of microsilica, 0.8 parts by weight of F14 activator, 12 parts by weight Input the water into the XLH-800 planetary wheel mill mixer for mixing and grinding, and the grinding time is 6 minutes to form a mixture;

[0069] 4) The mixture digestion process step is the same as the process step 4) of embodiment 1;

[0070] 5) Digestive material mixed and repeated wheel milling process steps: input 90 parts by weight of digested material, 10 parts by weight of consolidation agent, and 0.06 parts by weight of polycarboxylate superplasticizer into the XLH-800 planetary wheel mill for mixing Machine mixing, repeated round milling, milling tim...

Embodiment 3

[0074] A preparation process of non-sintered garbage tailings brick:

[0075] 1) Same as embodiment 1 process step (1);

[0076] 2) Same as embodiment 1 process step (2);

[0077] 3) Wheel grinding mixing process: 75.5 parts by weight of incineration residue, 6 parts by weight of MSW fly ash, 12 parts by weight of sea shell ash, 6 parts by weight of microsilica, 0.5 parts by weight of F14 activator, 13 parts by weight Input the water into the XLH-800 planetary wheel mill mixer for mixing and grinding, and the grinding time is 6 minutes to form a mixture;

[0078] 4) The mixture digestion process step is the same as the process step 4) of embodiment 1;

[0079] 5) Digestive material mixed and repeated wheel milling process steps: input 87 parts by weight of digested material, 13 parts by weight of consolidation agent, and 0.06 parts by weight of polycarboxylate superplasticizer into the XLH-800 planetary wheel mill for mixing Machine mixing, repeated round milling, milling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com