Method for constructing porous structure on surface of polyether ether ketone scaffold

A polyether ether ketone and porous structure technology, which is applied in the field of constructing porous structures on the surface of scaffolds, can solve the problems of short embedding time, poor osseointegration performance, incomplete leaching, etc., and achieve structural integrity maintenance, good osseointegration performance, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

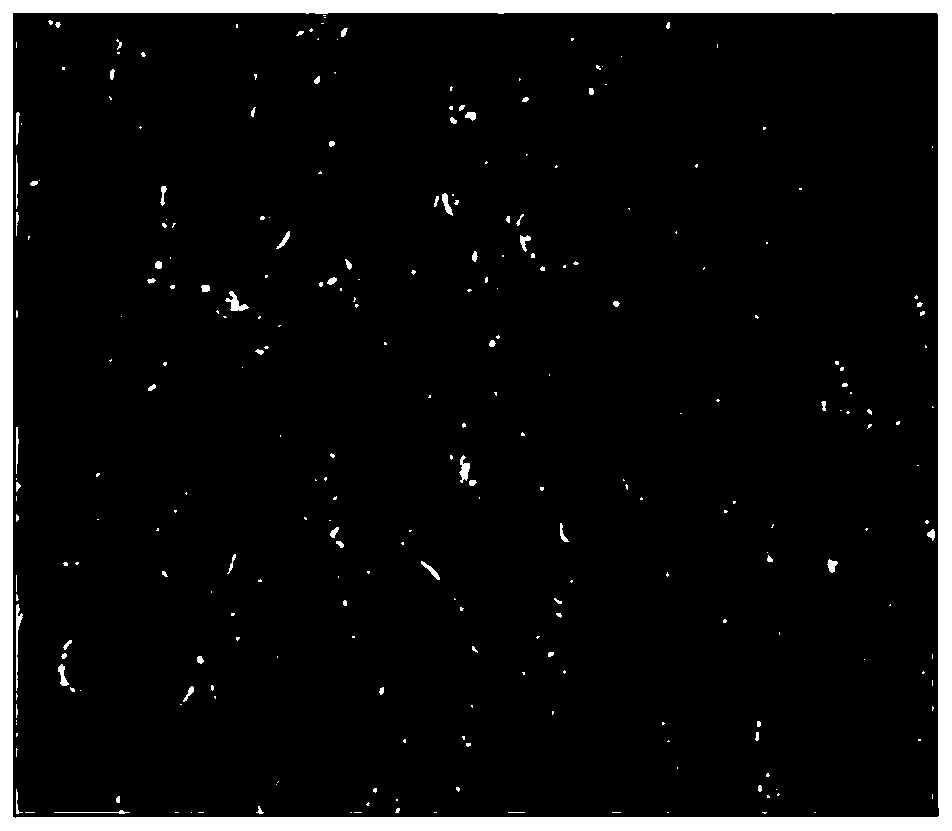

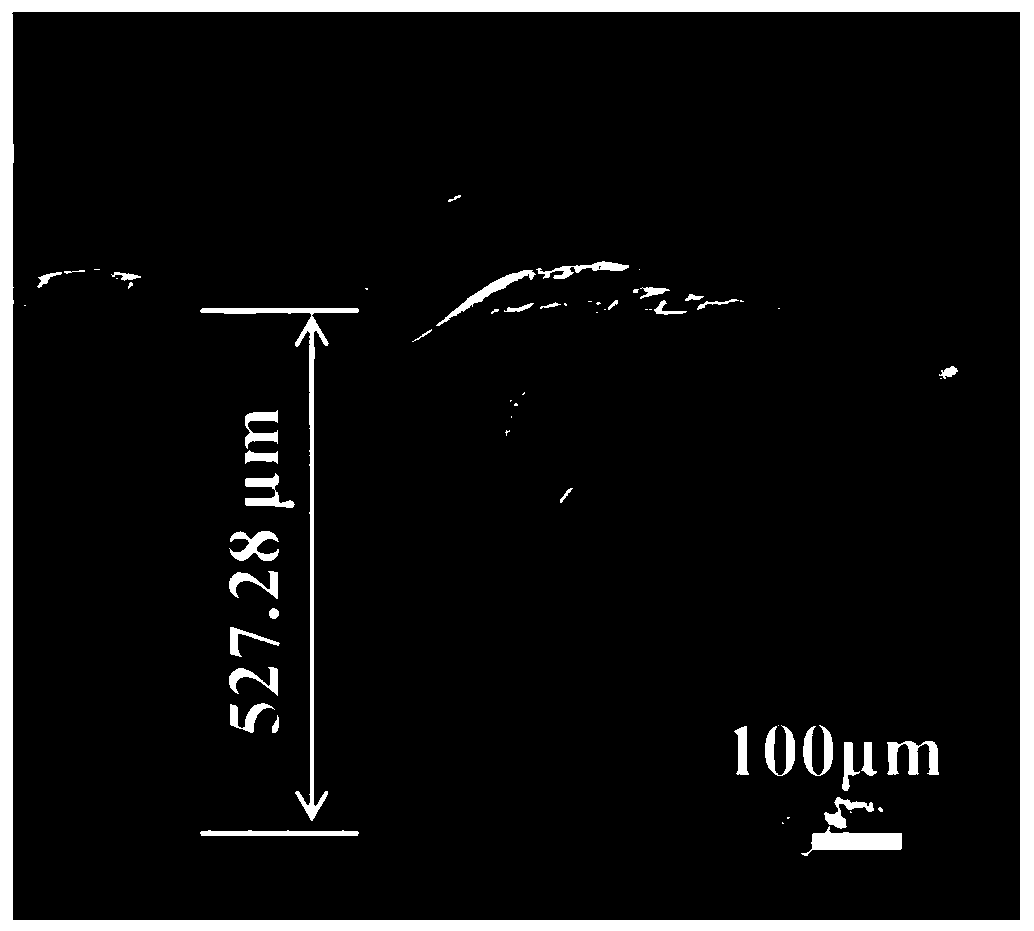

Image

Examples

Embodiment 1

[0024] A method for constructing a porous structure on the surface of a polyetheretherketone stent, the steps of which are:

[0025] A. Preparation of hard particles

[0026] Silicon dioxide (SiO 2 ) crushing and sieving to obtain silicon dioxide (SiO2) with a particle size of 200-800 microns 2 );

[0027] B. Embedding of hard particles

[0028] Grinding and polishing the surface of the polyetheretherketone stent, followed by ultrasonic cleaning with ethanol and deionized water; 2 ) adhered to the surface of the polyetheretherketone stent, and finally the polyetheretherketone stent was placed in a hot press, then the temperature was raised to 170°C and kept for 1.5h, and then a pressure of 2Mpa was applied, and the silicon dioxide (SiO 2 ) embedded in the surface of polyetheretherketone stent, and the surface is embedded with silicon dioxide (SiO 2 ) of polyetheretherketone stent;

[0029] C. Acid etching treatment

[0030] Place the polyetheretherketone stent prepared ...

Embodiment 2

[0033] A method for constructing a porous structure on the surface of a polyetheretherketone stent, the steps of which are:

[0034] A. Preparation of hard particles

[0035] Titanium dioxide (TiO 2 ) pulverized and sieved to obtain titanium dioxide (TiO2) with a particle size of 200-800 microns 2 );

[0036] B. Embedding of hard particles

[0037] Grinding and polishing the surface of the polyetheretherketone stent, followed by ultrasonic cleaning with ethanol and deionized water; then titanium dioxide (TiO 2 ) adhered to the surface of the polyetheretherketone stent, and finally the polyetheretherketone stent was placed in a hot press, then the temperature was raised to 170°C and kept for 1.5h, and then a pressure of 2Mpa was applied, and the titanium dioxide (TiO 2 ) embedded in the surface of polyetheretherketone stent, and the surface is embedded with titanium dioxide (TiO 2 ) of polyetheretherketone stent;

[0038] C. Acid etching treatment

[0039] The polyethere...

Embodiment 3

[0041] A method for constructing a porous structure on the surface of a polyetheretherketone stent, the steps of which are:

[0042] A. Preparation of hard particles

[0043] Zirconia (ZrO 2 ) pulverized and sieved to obtain zirconia (ZrO2) with a particle size of 200-800 microns 2 );

[0044] B. Embedding of hard particles

[0045] Zirconia (ZrO 2 ) adhered to the surface of the polyetheretherketone stent, then placed the polyetheretherketone stent in a hot press, then raised the temperature to 170-190°C and kept it warm for 1.5-2.5h, and then applied a pressure of 2-4Mpa, the carbon dioxide Zirconium (ZrO 2 ) embedded in the surface of polyetheretherketone stent, and the surface is embedded with zirconium dioxide (ZrO 2 ) of polyetheretherketone stent;

[0046] C. Acid etching treatment

[0047] The polyetheretherketone stent prepared in step B was placed in hydrofluoric acid (HF) for 44h, and the zirconium dioxide (ZrO2) on the surface of the polyetheretherketone sten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com