Prepreg, laminated board and printed wiring board

A prepreg and composition technology, applied in the direction of printed circuit, printed circuit, printed circuit components, etc., can solve the problems of signal delay, corrosiveness, toxic gas, environmental pollution, etc., and achieve the elimination of transmission delay and optimal glass transition The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment E1 to E6

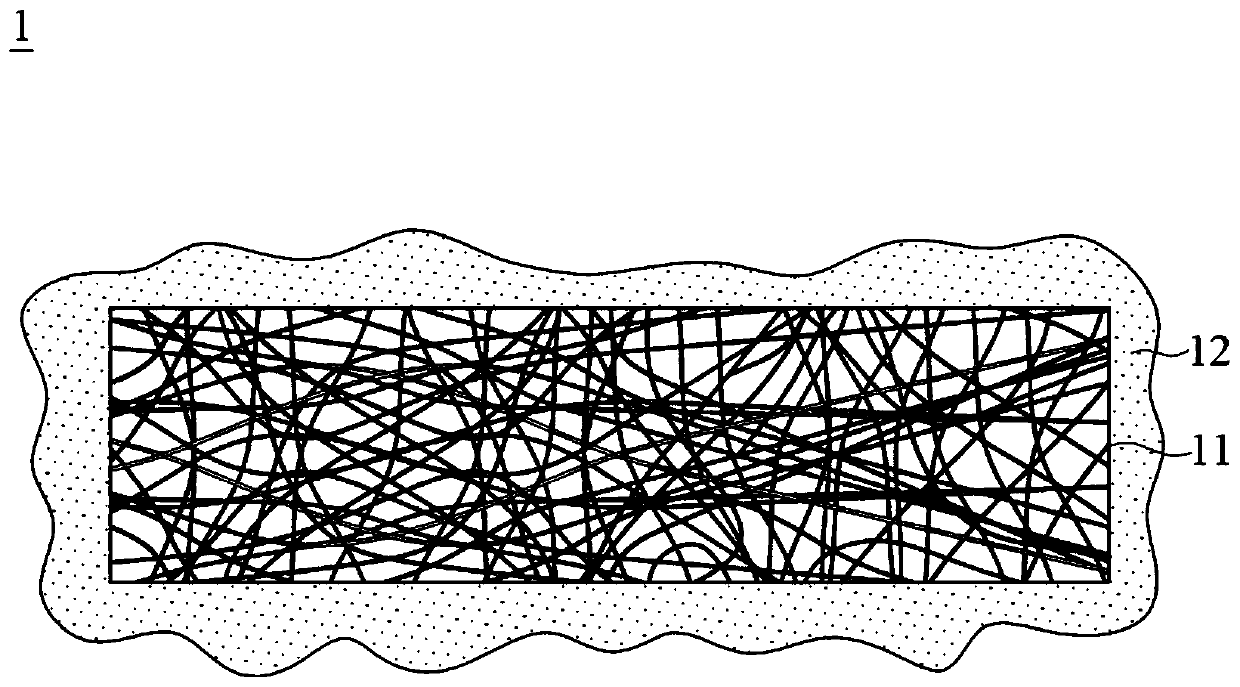

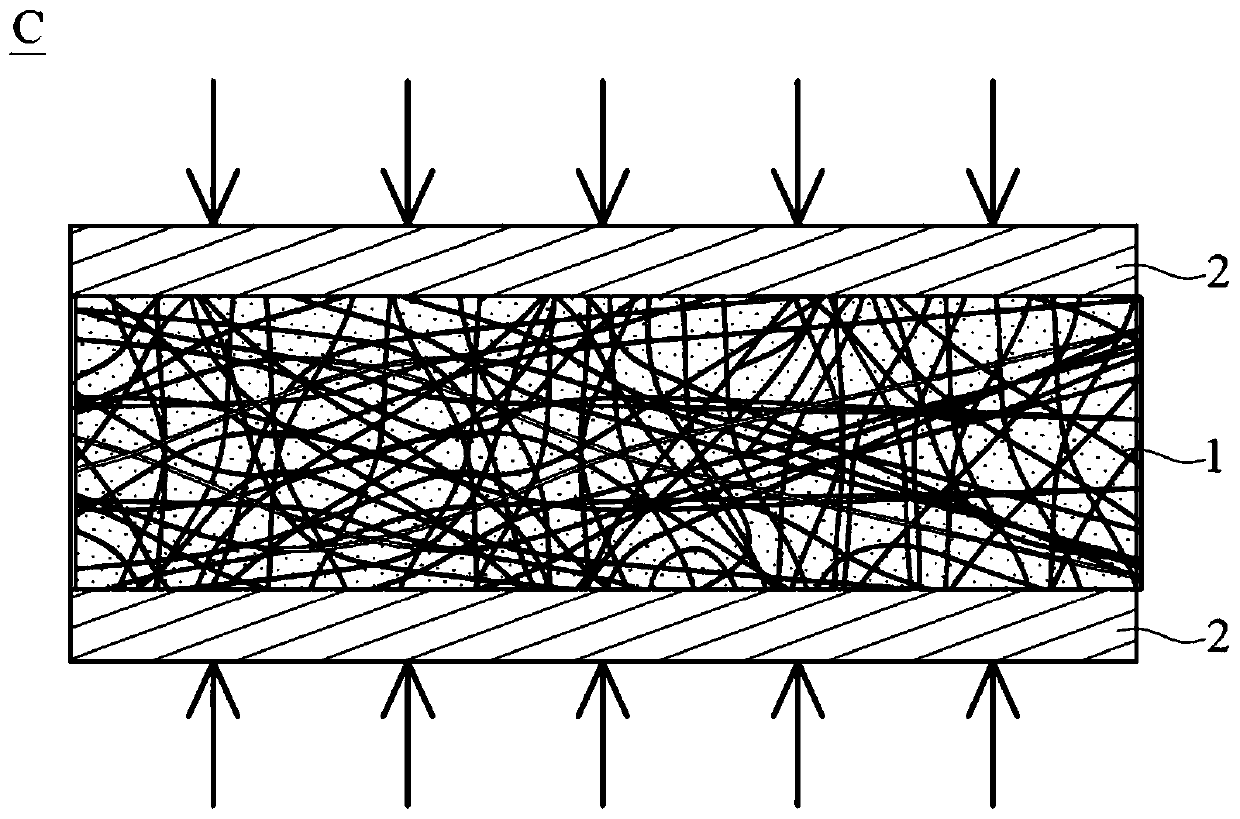

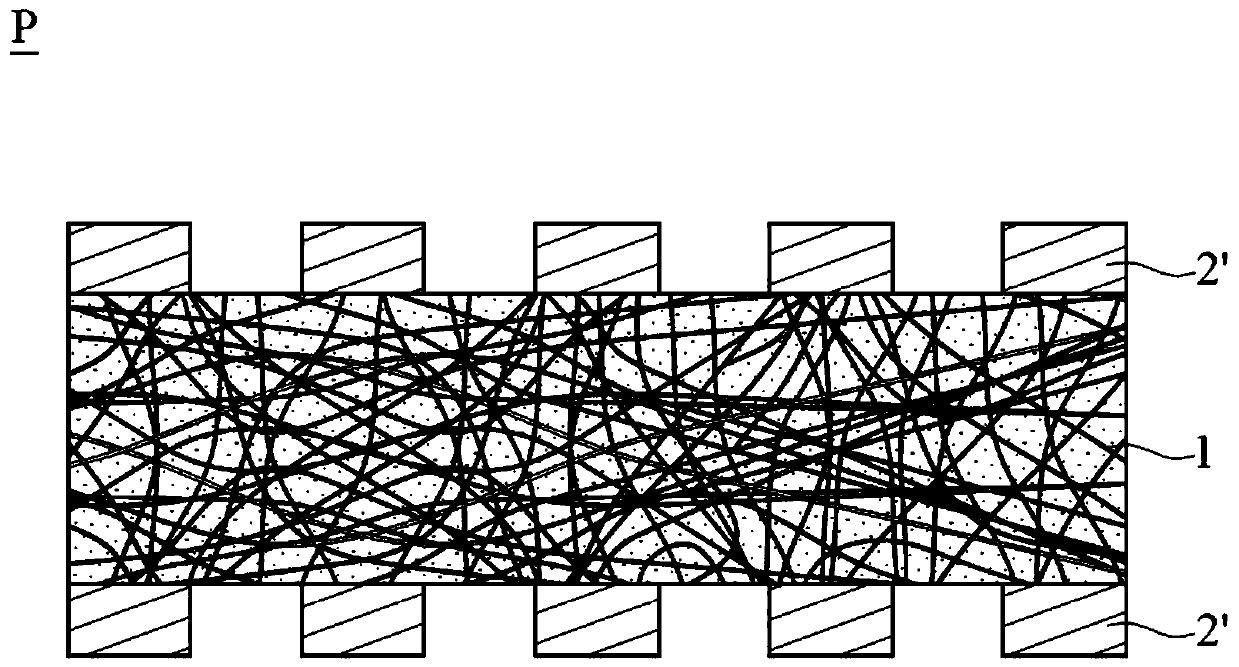

[0072] The compositions of Examples E1 to E6 are shown in Table 1 below. Examples E1 to E6 use non-woven PTFE mats as reinforcing materials, which are continuously passed through a series of rollers and enter the gluing tank, where the halogen-free epoxy resin composition of the present invention is loaded (as shown in Table 1). In the gluing tank, the reinforcing material is fully infiltrated by the halogen-free epoxy resin composition, and then the excess halogen-free epoxy resin composition is scraped off by the metering roller, and then baked in the gluing furnace for 100 to 180 minutes to evaporate the solvent and make it The resin is solidified, then cooled and rolled to form a resin substrate. The resin substrate and two 18μm copper foils were laminated in the order of copper foil, resin substrate, and copper foil, and then pressed at 220°C for 2 hours under vacuum to form a copper foil substrate.

[0073] Table 1

[0074]

[0075]

[0076] *NPTE4000 naphthalene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com