Method for preparing C14 diamine and long carbon chain nylon PA1414

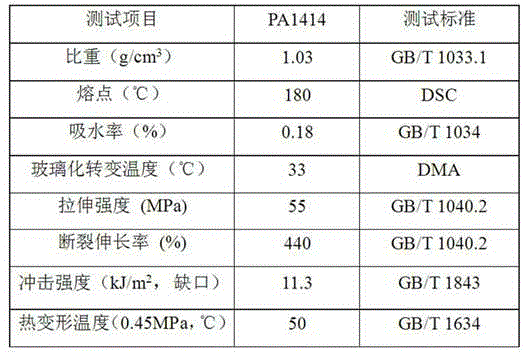

A technology of PA1414 and tetradecane dibasic acid, applied in the field of polymer synthesis, can solve the problems of high energy consumption and harsh reaction conditions, and achieve the effects of simple equipment, short production cycle and low glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing tetradecanediamine, comprising the steps of:

[0029] (1) Amination reaction: Add 1000kg of tetradecanedibasic acid into the ammoniation reactor, and add silica gel particles soaked in phosphoric acid as a catalyst. The dosage is 0.1% of the weight of tetradecanedioic acid, of which The content of tetradecanedibasic acid is 0.025% of the weight of tetradecanedibasic acid. When the temperature is raised to 160°C, the flow rate of ammonia gas is controlled to be 20-25m 3 / h, the temperature is raised to 310°C within 5h stepwise, and the ammonia gas is continuously introduced, and the flow rate of the ammonia gas is controlled to be 0.5~3m 3 / h, carry out insulation 2h, then this reactant is squeezed in the thick nitrile storage tank with pump, leaves standstill and separates out catalyst recovery, then sucks thick nitrile in the distillation still with vacuum, finally vacuumizes and depressurizes to-0.098MPa, Simultaneously heat up, when still temp...

Embodiment 2

[0040] A method for preparing tetradecanediamine, comprising the steps of:

[0041] (1) Amination reaction: Add 1000kg of tetradecanedibasic acid into the ammoniation reactor, and add silica gel particles soaked in benzenesulfonic acid as a catalyst, the dosage is 0.2% of the weight of tetradecanedioic acid, The content of benzenesulfonic acid is 0.04% of the weight of tetradecanedibasic acid, the temperature is raised to 150°C, ammonia gas is introduced, and the flow rate is controlled at 20-25 m 3 / h, within 5 hours, the temperature is raised to 305°C step by step, and the ammonia gas is continuously introduced, and the flow rate of the ammonia gas is controlled at 0.5-4m 3 / h, keep warm for 2h, then pump the reactant into the thick nitrile storage tank, let it stand to separate the catalyst, then suck it into the still with vacuum, finally vacuumize and depressurize to -0.098MPa, and heat Raise the temperature, when the temperature of the kettle rises to 260°C, the tempera...

Embodiment 3

[0048] A method for preparing tetradecanediamine, comprising the steps of:

[0049] (1) Amination reaction: Add 1000kg tetradecanedibasic acid into the ammoniation reactor, and add silica gel particles soaked in p-toluenesulfonic acid as a catalyst, and the dosage is 0.5% of the weight of tetradecanedibasic acid , wherein the content of p-toluenesulfonic acid is 0.05% of the weight of tetradecanedibasic acid, the temperature is raised to 155°C, ammonia gas is introduced, and the flow rate is controlled at 20-25m 3 / h, at the same time, the temperature is raised to 310 ° C in steps within 5 hours, and the ammonia gas is continuously introduced, and the flow rate of the ammonia gas is controlled to be 0.5 ~ 3m 3 / h, keep warm for 2h, then pump the reactant into the thick nitrile storage tank, let it stand and separate the catalyst for recovery, then use vacuum to suck it in the distillation still, and finally vacuumize and depressurize to -0.096MPa. Heating to raise the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com