Aqueous two-component safety airbag cover decoration elastic hand feeling coating material and preparation method thereof, and coating formed by elastic hand feeling coating material

A water-based two-component, airbag technology, applied in the field of coatings, can solve the problems of environmental pollution, human health, harmfulness, and poor touch of the coating, and achieve the effects of saving costs and processes, good hand feeling, and excellent chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

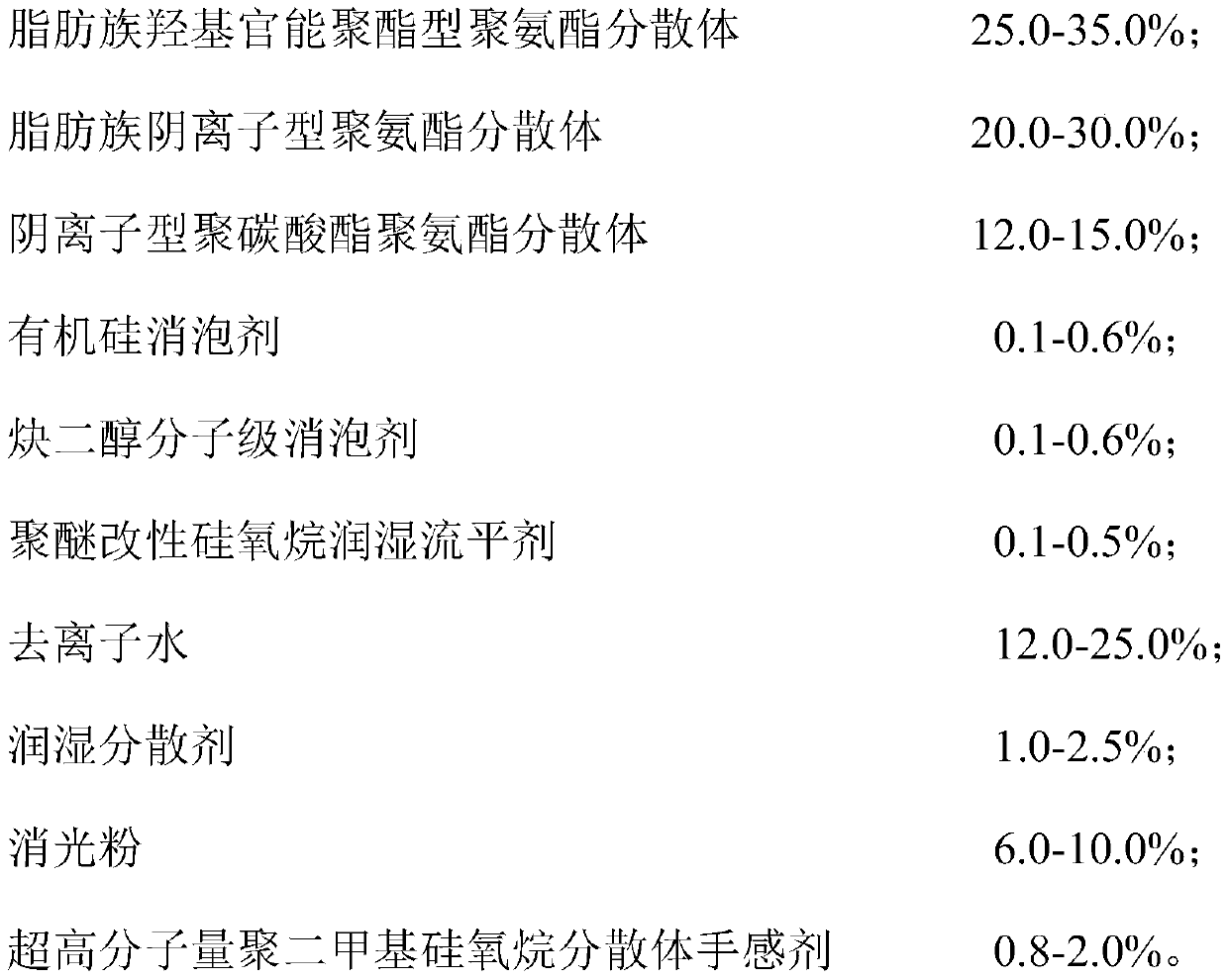

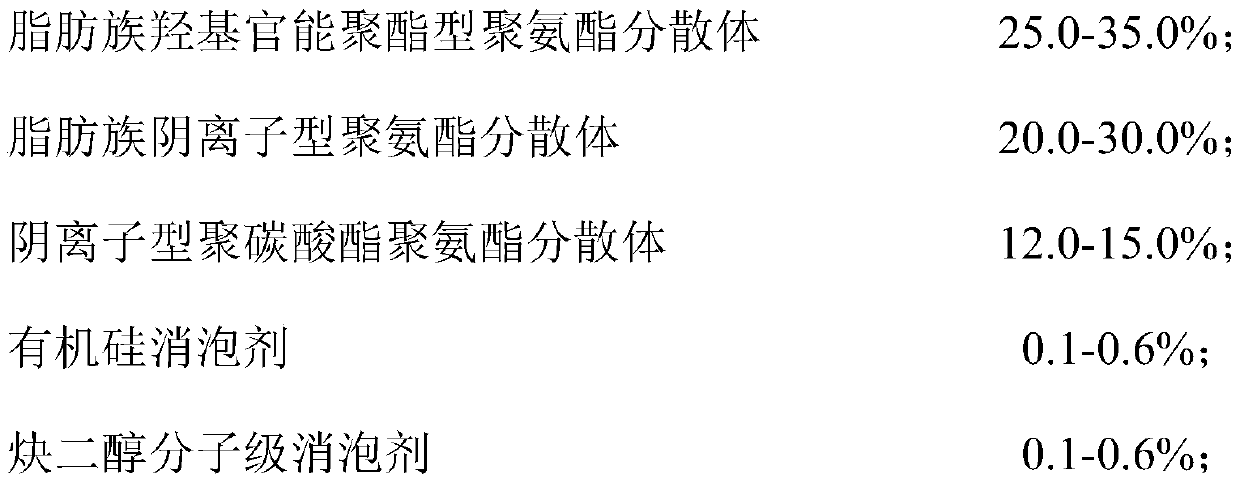

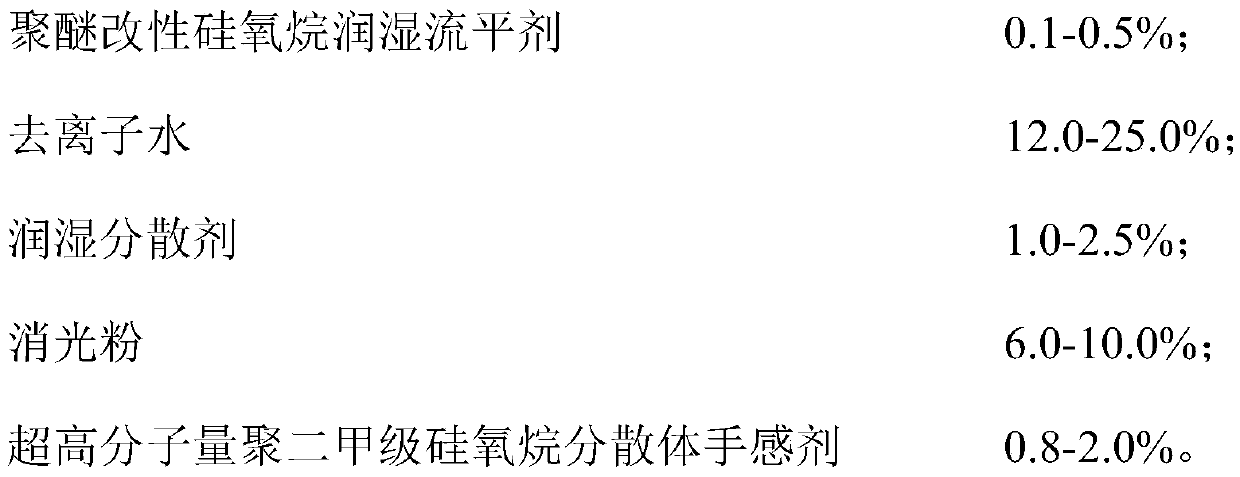

[0042] A water-based two-component airbag cover decoration elastic feel paint, including the raw materials shown in the weight percentage of embodiment 1 in table 1:

[0043] Table 1

[0044]

[0045]

[0046] The preparation method of described water-based two-component airbag cover decoration elastic handle coating comprises the following steps:

[0047] (1) the aliphatic hydroxyl functional polyester polyurethane dispersion of formula quantity U XP 2698, Aliphatic Anionic Polyurethane Dispersion Mix UH 340 / 1, stir at a low speed of 500-700 rpm, add silicone defoamer BYK-093, polyether modified siloxane wetting and leveling agent BYK-348, ultra-high molecular weight poly Silicone dispersion hand feel agent DC-51, deionized water with 70% formulation amount, acetylene glycol molecular grade defoamer MD-20, wetting and dispersing agent DISPERBYK-192, stir for 10 minutes;

[0048] (2) Under low-speed stirring at 300-500 rpm, continue to add formula amounts of 1.5 μm ...

Embodiment 2

[0053] A water-based two-component airbag cover decoration elastic feel paint, including the weight of the raw materials shown in Example 2 in Table 1, its preparation method is the same as Example 1.

[0054] Mix and stir the water-based two-component elastic handle paint for airbag cover decoration prepared in this example with curing agent and deionized water according to the weight ratio of 100:7:7, and spray it directly on TPS-SEBS or TPS-SBS On the substrate of the airbag cover trim made of +PP, after baking at 80°C for 50-60 minutes, a coating is formed on the surface of the airbag cover trim substrate, and the properties of the obtained coating are shown in Table 2. The curing agent consists of 80 parts of hydrophilic modified aliphatic polyisocyanate 304 and 20 parts of PGDA are mixed and stirred evenly.

Embodiment 3

[0056] A water-based two-component airbag cover decoration elastic handle coating, including the weight of the raw material shown in Example 3 in Table 1, its preparation method is the same as Example 1.

[0057] Mix and stir the water-based two-component elastic handle paint for airbag cover decoration prepared in this example with curing agent and deionized water according to the weight ratio of 100:7:7, and spray it directly on TPS-SEBS or TPS-SBS On the substrate of the airbag cover trim made of +PP, after baking at 80°C for 50-60 minutes, a coating is formed on the surface of the airbag cover trim substrate, and the properties of the obtained coating are shown in Table 2. The curing agent consists of 80 parts of hydrophilic modified aliphatic polyisocyanate 304 and 20 parts of PGDA are mixed and stirred evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com