A kind of preparation method of antifungal peptide of plum fish processing by-product

An antifungal peptide and by-product technology, applied in the field of antifungal peptide preparation, can solve the problem of low antibacterial activity and achieve the effect of high antibacterial activity, rich variety and good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

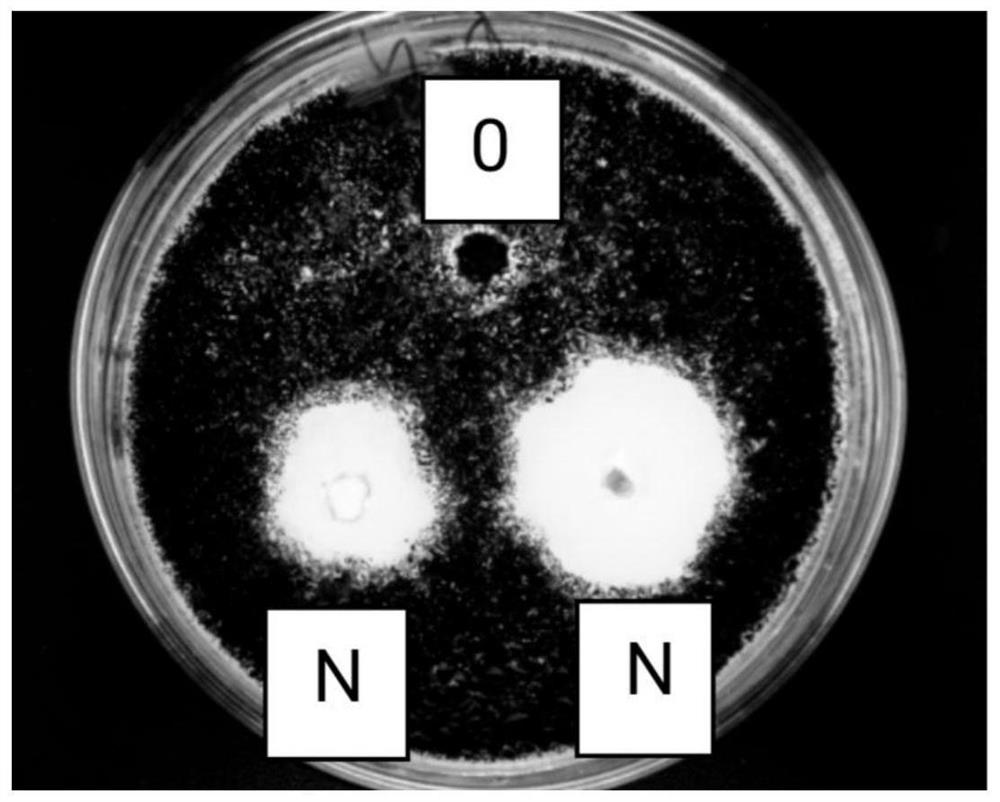

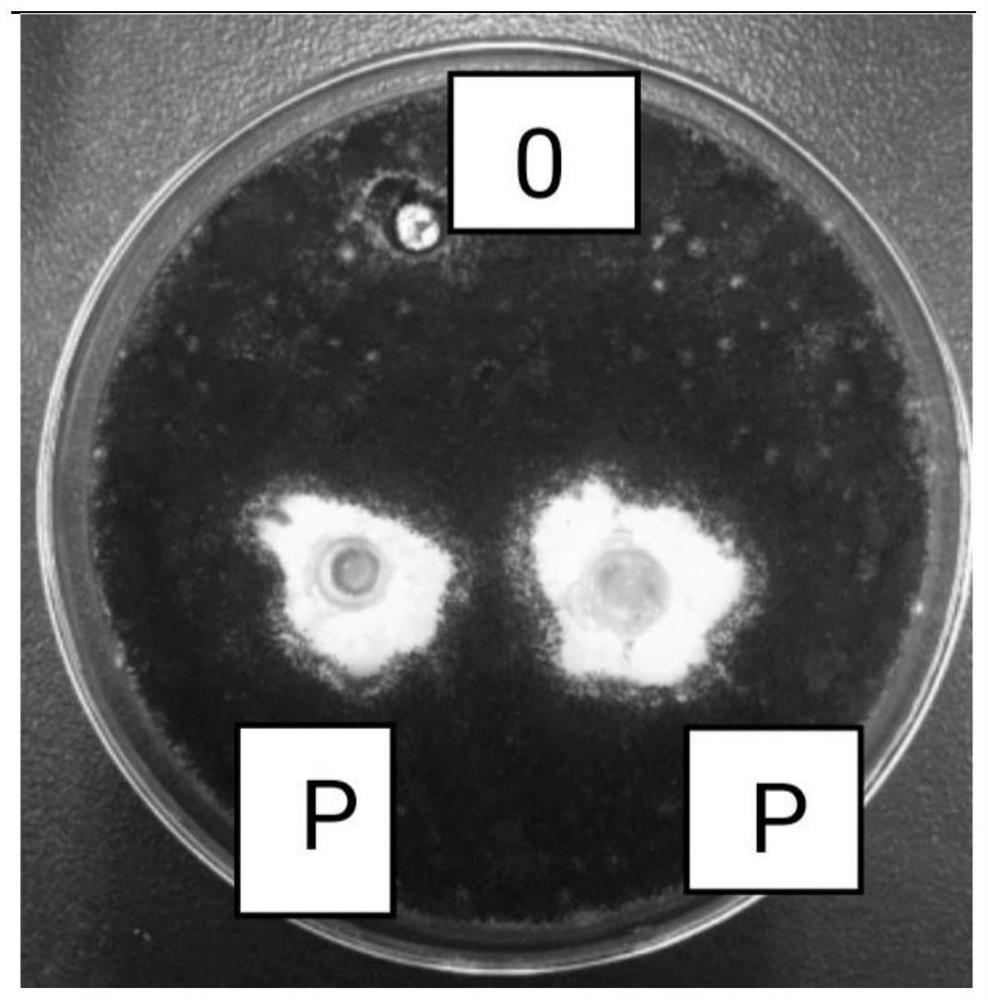

Image

Examples

Embodiment 1

[0032] A method for preparing antifungal peptides of plum fish processing by-products is characterized in that it comprises the following preparation steps:

[0033] (1) Pretreatment: Wash the plum fish head and mince it, and degrease it with 95% methanol in a water bath for 2.1 hours at a material-to-liquid ratio of 1:7.5 (m / v) and a temperature of 50°C; After degreasing, pour off the supernatant, wash the precipitate with pure water, centrifuge the defatted fish head meat at 2°C, 11950 r / min for 23 minutes, and collect the precipitate;

[0034] (2) Enzymolysis: add the fish head meat to the enzymatic hydrolysis liquid containing neutral protease for enzymatic hydrolysis; wherein, the concentration of neutral protease is 0.2wt%, and the mass of the enzymatic hydrolysis liquid is 3 times the mass of the fish head meat , the enzymolysis temperature is 40°C, the pH of the enzymolysis solution is controlled at 5.5, and the enzymolysis time is 5.2h;

[0035] (3) Filtrate the clar...

Embodiment 2

[0043] A method for preparing antifungal peptides of plum fish processing by-products is characterized in that it comprises the following preparation steps:

[0044] (1) Pretreatment: Wash the plum fish head and mince it, and degrease it with 94% methanol water bath for 2 hours under the condition of solid-liquid ratio of 1:6 (m / v) and temperature of 48°C; degrease Finally, pour off the supernatant, wash the precipitate with pure water, and centrifuge the defatted fish head meat at 0°C and 11900 r / min for 20 minutes to collect the precipitate;

[0045] (2) Enzymolysis: add the fish head meat to the enzymatic hydrolysis liquid containing neutral protease for enzymatic hydrolysis; wherein, the concentration of neutral protease is 0.05wt%, and the mass of the enzymatic hydrolysis liquid is twice the mass of the fish head meat , the enzymolysis temperature is 30°C, the pH of the enzymolysis solution is controlled at 5, and the enzymolysis time is 5 hours;

[0046] (3) To obtain t...

Embodiment 3

[0054] A method for preparing antifungal peptides of plum fish processing by-products is characterized in that it comprises the following preparation steps:

[0055] (1) Pretreatment: Wash the plum fish head and mince it, and degrease it with 96% methanol in a water bath for 2.2 hours at a material-to-liquid ratio of 1:9 (m / v) and a temperature of 52°C; After degreasing, pour off the supernatant, wash the precipitate with pure water, centrifuge the defatted fish head meat at 4°C, 12000 r / min for 25 minutes, and collect the precipitate;

[0056] (2) Enzymolysis: Add the fish head meat to the enzymatic hydrolysis liquid containing neutral protease for enzymatic hydrolysis; wherein, the concentration of neutral protease is 0.25wt%, and the mass of the enzymatic hydrolysis liquid is 4 times the mass of the fish head meat , the enzymolysis temperature is 45°C, the pH of the enzymolysis solution is controlled at 6, and the enzymolysis time is 5.4h;

[0057] (3) To obtain the clarif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com