Oil agent for carbon fiber precursor

A technology of carbon fiber precursor and oil agent, which is applied in the field of oil agent and textile oil agent, can solve the problems of sticking rollers that cannot be completely solved, fiber bundle damage production and safety, and increase the workload of on-site personnel, etc., to achieve the solution of sticking Effect of roller phenomenon, reduction of labor intensity, wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and comparative example 1~4

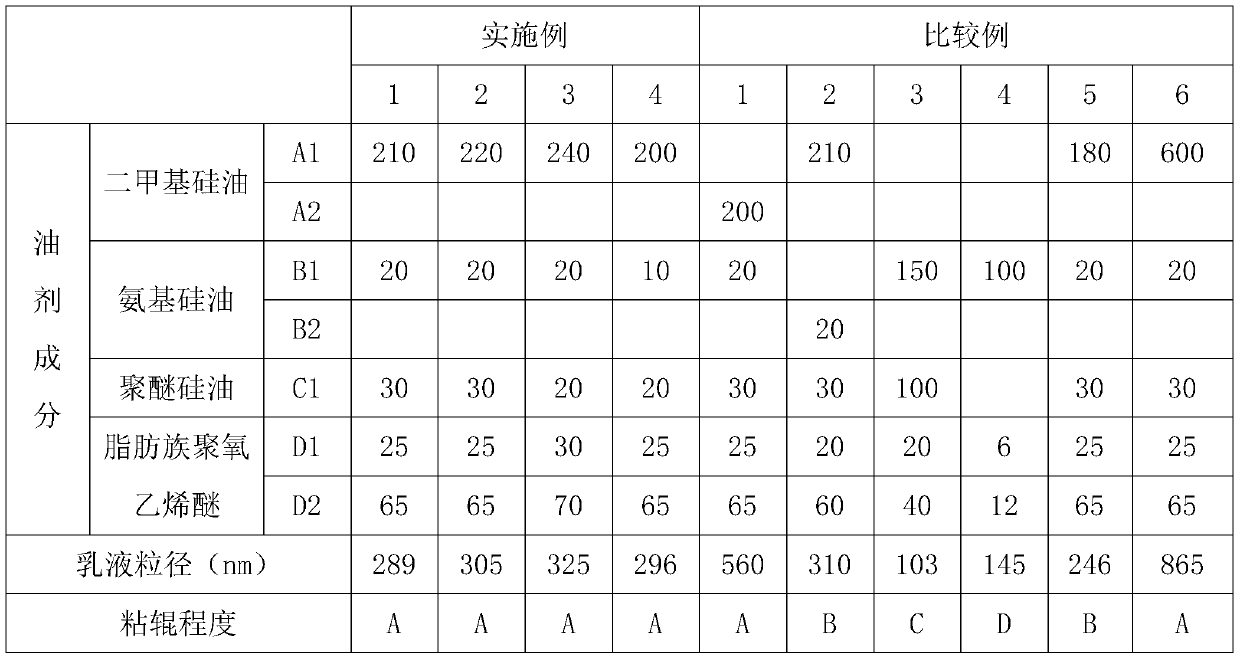

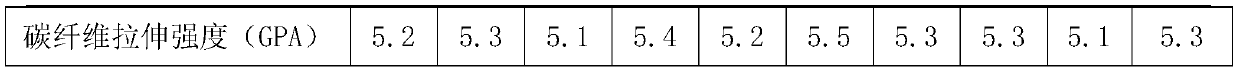

[0036] According to the oil components and parts by mass shown in Table 1 below, mix dimethyl silicone oil, amino silicone oil, polyether silicone oil, and aliphatic polyoxyethylene ether, and stir to make it evenly mixed; slowly add deionized water, Use a homogenizer or a high-speed shear emulsifier to emulsify to obtain an emulsion with a solid content of 30 wt%. The results of measuring the particle size of the emulsion are shown in Table 1.

[0037] Dilute the emulsion with water to 2%, and add it to the oiling tank with circulation function. The spinning stock solution obtained after the dimethyl sulfoxide solution of the PAN copolymer has been treated with single removal and defoaming is sprayed into a certain concentration of DMSO aqueous solution through the spinneret under the action of the metering pump, which is the so-called coagulation bath. In the process, the PAN copolymer is solidified into a fibrous form, and the obtained PAN primary fiber is carried out unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com