Method for testing swellability of carbonization process of magnesium oxide solidified soil and shear strength of carbonized soil

A carbonization process and shear strength technology, which is used in soil material testing, using a stable shear force to test material strength and strength characteristics, etc. The mechanical parameters of carbonized soil are inaccurate, and the temperature and resistivity of soil samples cannot be completed, so as to avoid sample damage and stress release, avoid water vapor accumulation, and meet the test effect of shear strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

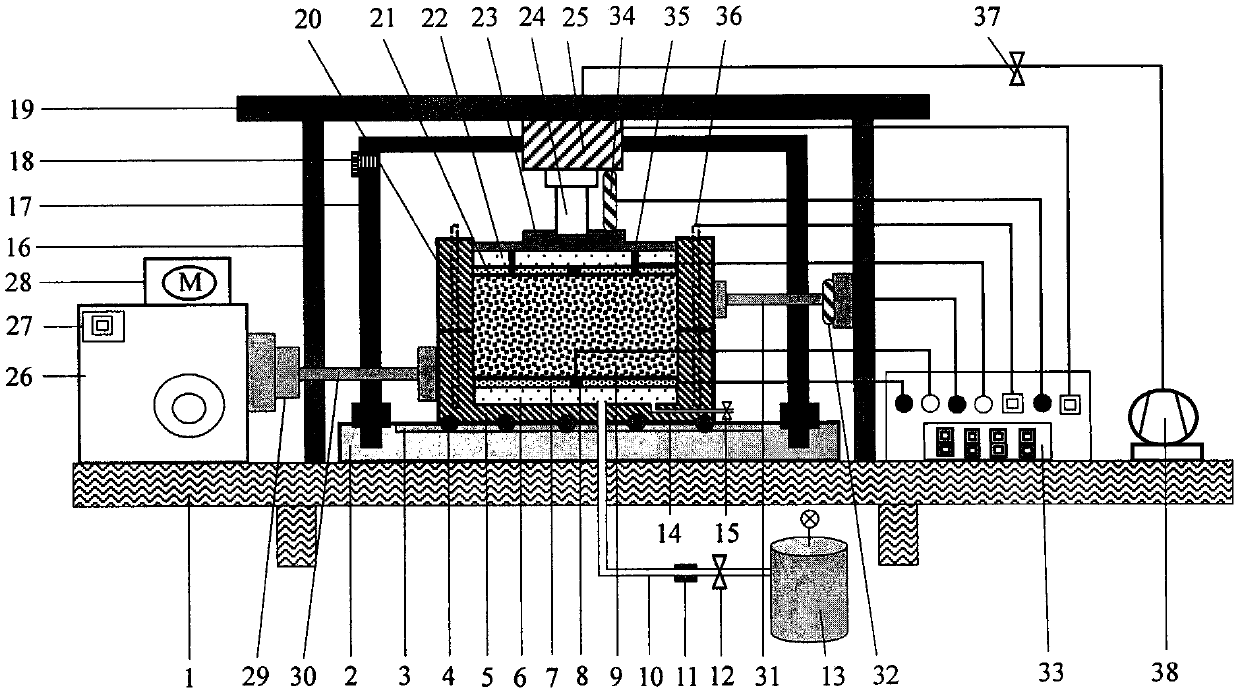

[0035] A method for testing expansibility of magnesia solidified soil carbonization process and carbonized soil shear strength, comprising the following steps:

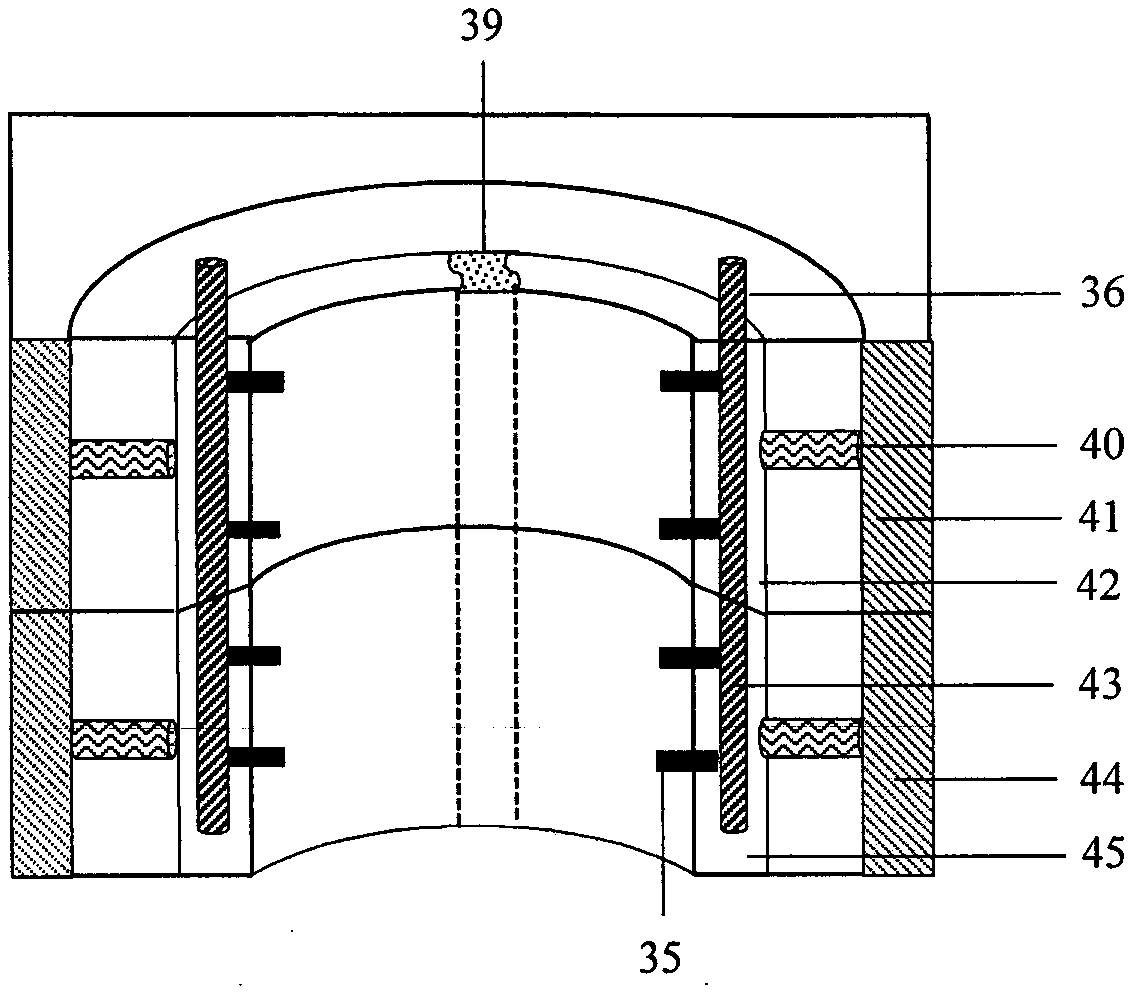

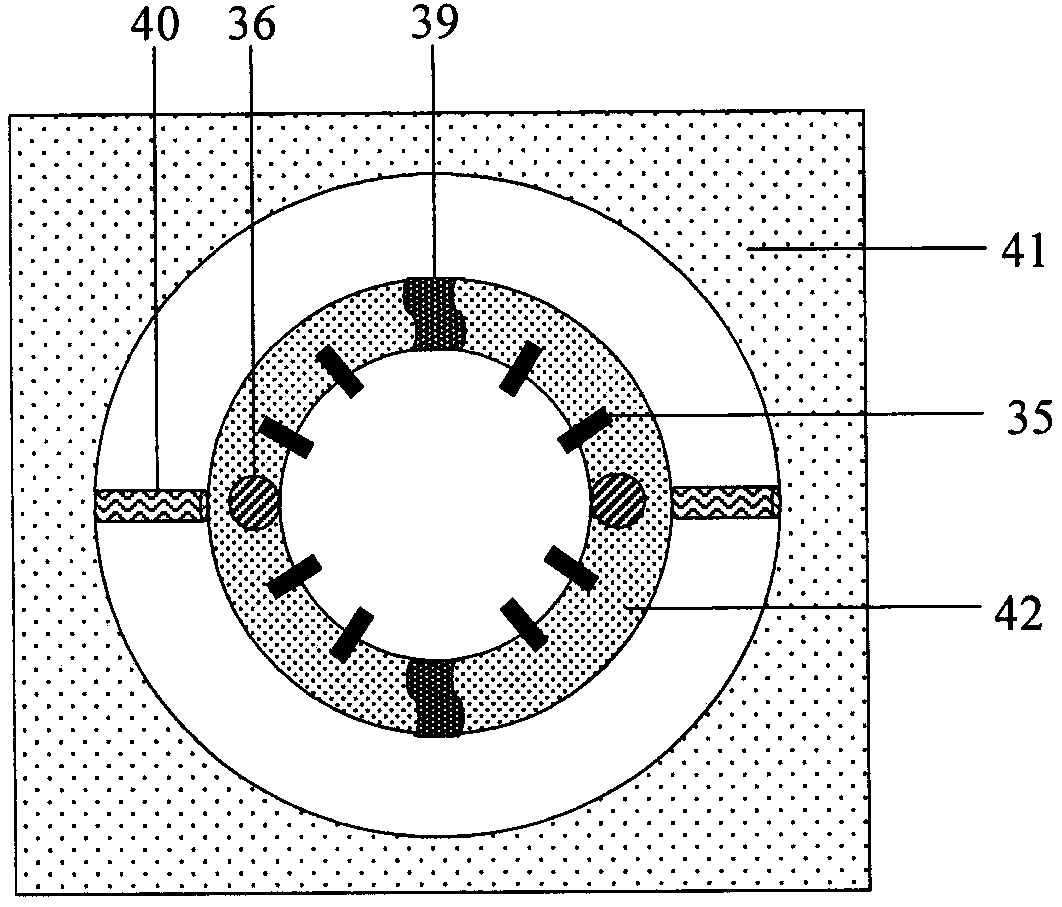

[0036] a. Device assembly and connection: Place the lower permeable plate 6, filter paper, lower electrode plate 7 and temperature sensor 8 in the lower shear box 5 in sequence, place the upper shear box 20 on the lower shear box 5, and adjust the temperature in the shear box. All the spring bolts 40 make the two petals of the upper shear box inner shell 42 and the lower shear box inner shell 45 tightly closed, and apply vaseline on the inner walls of the upper shear box inner shell 42 and the lower shear box inner shell 45 , adjust the upper reel 36 and the lower reel 43 and connect them together, so that the lower shear box 5 and the upper shear box 20 are stabilized as a whole;

[0037] b. Sample preparation: Use a ring knife to prepare magnesium oxide mixed soil sample 9 under different compaction degrees, and use...

Embodiment 2

[0047] On the basis of the above-mentioned embodiment 1, some key points are described through specific parameters. Using a ring knife to make a cylindrical sample 9 with an optimal water content, a compactness of 92%, a diameter of 6.18 cm, and a height of 2.0 cm, place the lower permeable plate 6, filter paper and lower electrode plate 7 in sequence in the lower shear box 5, Then press the ring knife sample into the shear box, and then place the upper electrode plate 21, the filter paper and the upper water-permeable plate 22 sequentially on the top of the sample. Then, the upper reel 36, the lower reel 43, and the balance plate 23 are automatically adjusted by the controller 33, so that the strain gauge 35 rotates as a whole and corresponds to the upper shear box inner shell 42, the lower shear box inner shell 45, and the upper permeable plate 22. Leave hole 46. Due to the small height of the sample, four strain gauges 35 at the same interval can be arranged respectively i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com