Preparation method and application of a porous carbon-coated PdFe/C alloy nano-frame

A technology of alloying nanometer and porous carbon, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as hindering active sites, reducing catalytic performance, reducing mass transfer rate, etc. Aggregation and dissolution, enhanced electrocatalytic activity, and favorable effects on graphitization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] More specifically, the preparation method of the porous carbon-coated PdFe / C alloy nanoframe of the present invention specifically includes the following steps:

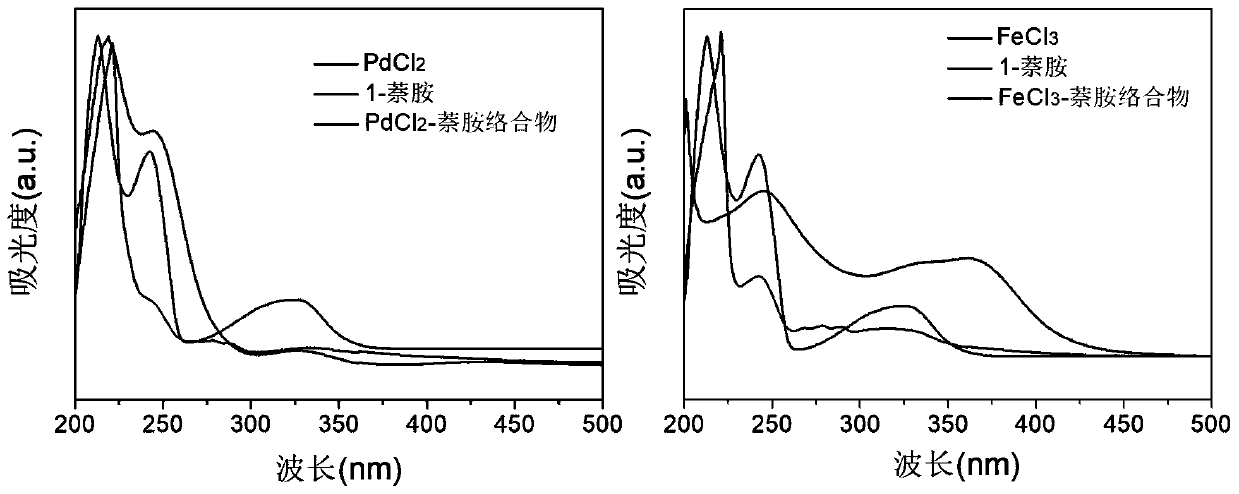

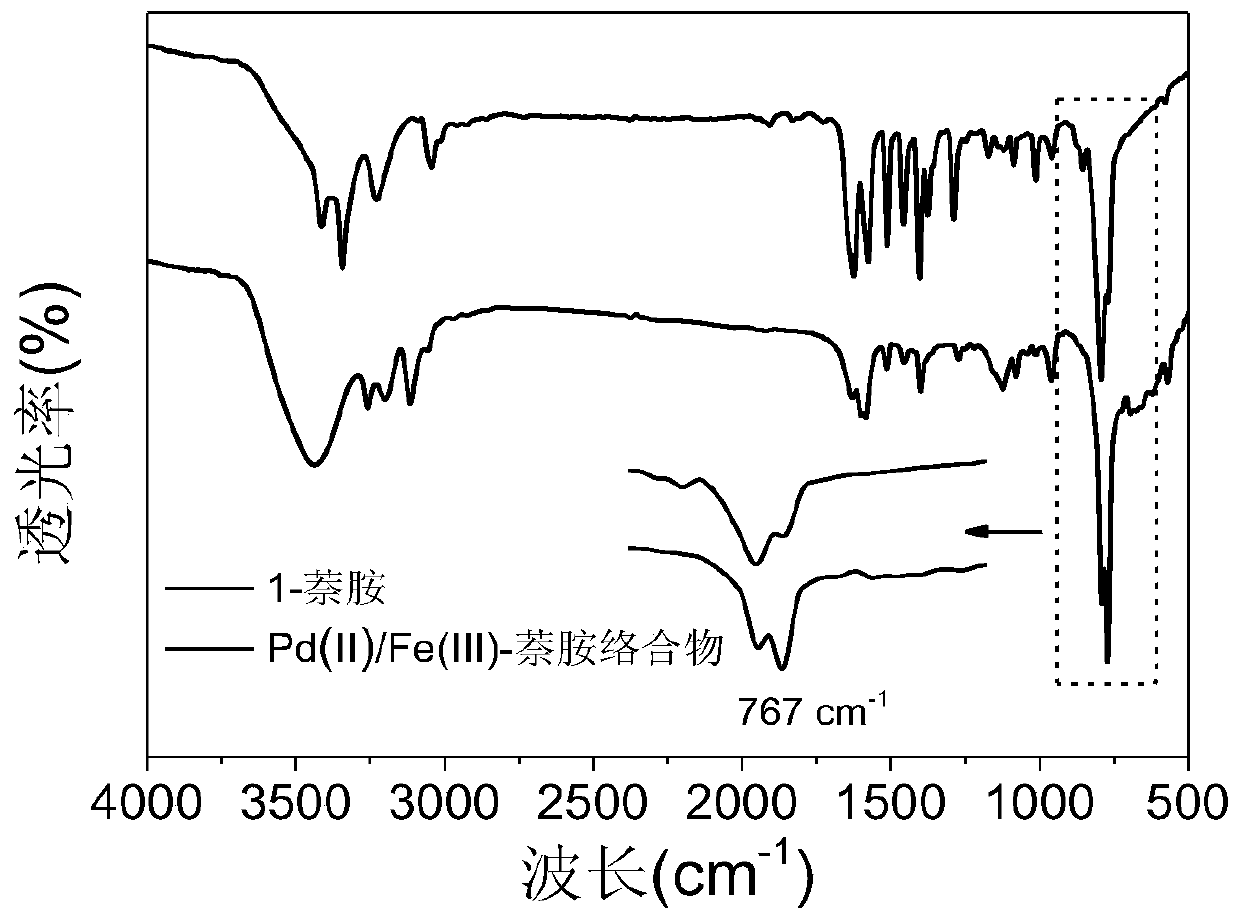

[0034] 1) Synthesis of yellow sheet-like Pd(II)-naphthylamine complex: take a certain amount of naphthylamine (C 10 h 9 N), dissolved in ethanol, added PdCl 2 Aqueous solution, fully ultrasonically mixed, after standing still, a yellow flaky Pd(II)-naphthylamine complex precipitate can be obtained, and the supernatant is removed by centrifugation;

[0035] 2) Synthesis of yellow-green flaky Pd(II) / Fe(III)-naphthylamine complex: place the obtained yellow precipitate in FeCl 3 In the mixed solution of water and ethanol, after sufficient ultrasonic dispersion, stir overnight, so that the 1-naphthylamine molecule on the surface of the sheet-like Pd(II)-naphthylamine complex fully adsorbs Fe(III), and centrifugal drying;

[0036] 3) Preparation of porous carbon-coated PdFe / C alloy nanoframes: heat the yellow-gre...

Embodiment 1

[0046] The preparation method of porous carbon coated PdFe / C alloy nano-frame, comprises the following steps:

[0047] 1) Preparation of yellow flaky Pd(II)-naphthylamine complex: take 286mg naphthylamine (C 10 h 9 N) Dissolved in 4mL of ethanol, fully ultrasonicated to dissolve; add 4mL 0.05mol L -1 PdCl 2 Aqueous solution, after standing still, yellow flake Pd(II)-naphthylamine complex can be obtained, which is centrifuged and dried;

[0048] 2) Synthesis of yellow-green flaky Pd(II) / Fe(III)-naphthylamine complex: place the resulting yellow precipitate in 4mL0.05mol L -1 FeCl 3 In a mixed solution with a water-ethanol volume ratio of 1:1, after fully ultrasonically dispersed, stir for 24 hours, so that the 1-naphthylamine molecules on the surface of the flaky Pd(II)-naphthylamine complex can fully absorb Fe(III) , centrifugal drying;

[0049] 3) Preparation of porous carbon-coated PdFe / C alloy nanoframes: the yellow-green powder obtained in step 2) was prepared in a ni...

Embodiment 2

[0051] The preparation method of porous carbon coated PdFe / C alloy nano-frame, comprises the following steps:

[0052] 1) Preparation of yellow flaky Pd(II)-naphthylamine complex: Weigh 0.286mg naphthylamine (C 10 h 9 N) Dissolved in 4mL of ethanol, fully ultrasonicated to dissolve; add 4mL 0.05mol L -1 PdCl 2 Aqueous solution, after standing still, yellow flake Pd(II)-naphthylamine complex can be obtained, which is centrifuged and dried;

[0053] 2) Synthesis of yellow-green flaky Pd(II) / Fe(III)-naphthylamine complex: place the resulting yellow precipitate in 4mL0.05mol L -1 FeCl 3 In a mixed solution with a water-ethanol volume ratio of 1:1, after fully ultrasonically dispersed, stir for 24 hours, so that the 1-naphthylamine molecules on the surface of the flaky Pd(II)-naphthylamine complex can fully absorb Fe(III) , centrifugal drying;

[0054] 3) Preparation of porous carbon-coated PdFe / C alloy nanoframes: the yellow-green powder obtained in step 2) was prepared in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com