Catalyst slurry for proton exchange membrane fuel cells and preparation method thereof

A technology of proton exchange membrane and catalyst slurry, which is applied in the direction of fuel cells, battery electrodes, electrochemical generators, etc., can solve the problems of high environmental protection pressure, easy combustion, high temperature, etc., and achieve good life and durability, non-combustibility, and structure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

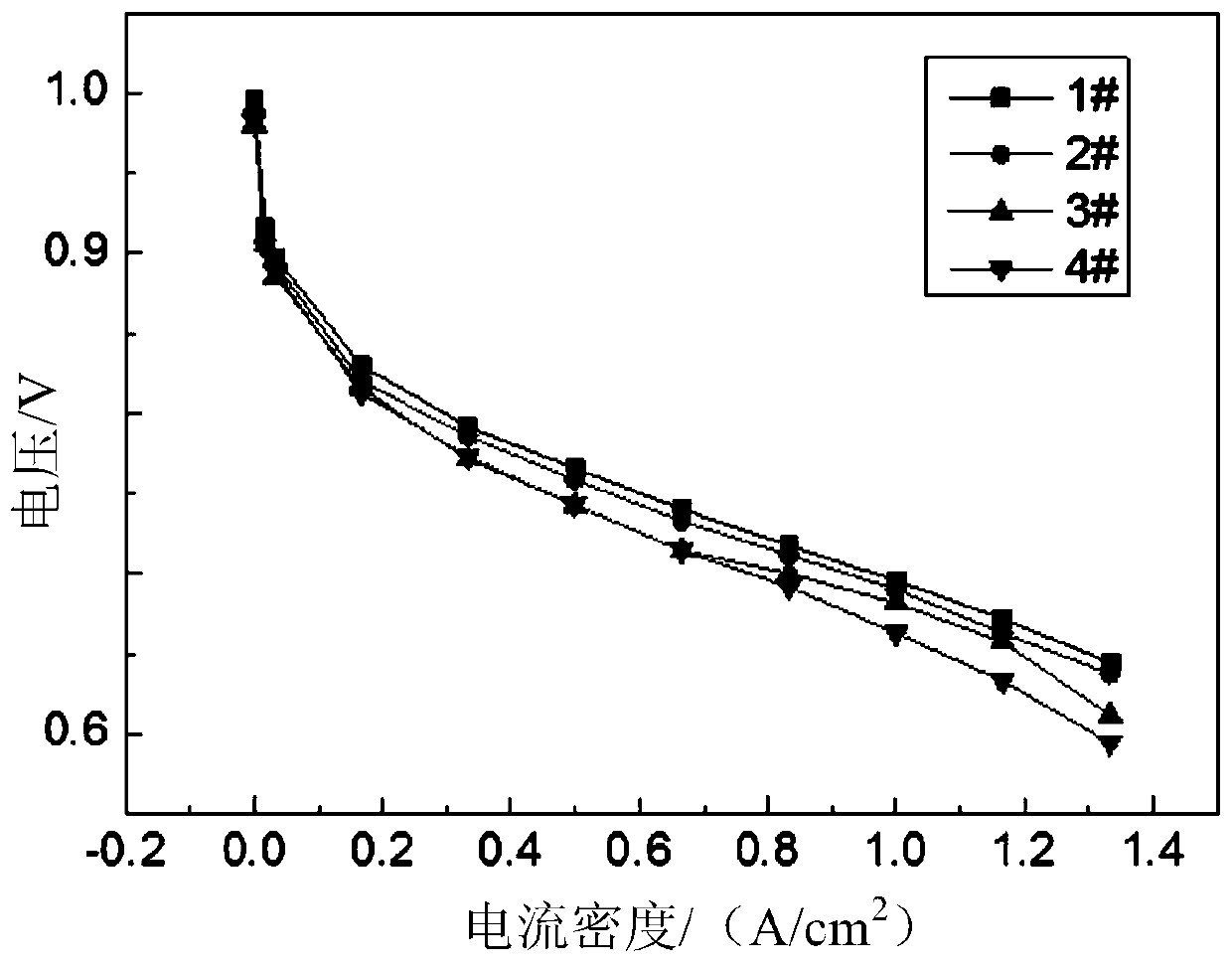

Image

Examples

Embodiment 1

[0028] A preparation method for a catalyst slurry for a proton exchange membrane fuel cell, comprising the following steps:

[0029] (1) Preparation of 5wt.% perfluorosulfonic acid resin dispersion

[0030] Mix 5wt% perfluorosulfonic acid resin, 45wt.% water and 50wt.% alcohol, put the mixed solution into a high-pressure reactor and seal it, pressurize to 4bar, heat to 240°C, stir for 4 hours, and cool to obtain 5 % perfluorosulfonic acid resin dispersion;

[0031] (2) Catalyst slurry preparation

[0032] Weigh 0.5g 60%Pt / C catalyst, 4g 5wt.% perfluorosulfonic acid resin dispersion prepared in step (1), 8g acetic acid, 1g isopropanol, 0.05g malic acid, 1g water, mix and ultrasonically stir for 30min , to prepare catalyst slurry.

Embodiment 2

[0034] A preparation method for a catalyst slurry for a proton exchange membrane fuel cell, comprising the following steps:

[0035] (1) Preparation of 20wt.% perfluorosulfonic acid resin dispersion

[0036] Mix 20wt.% perfluorosulfonic acid resin, 40wt.% water and 40wt.% alcohol, put the mixed solution into a high-pressure reactor and seal it, pressurize to 5bar, heat to 260°C, stir for 6 hours, and cool to obtain 20% perfluorosulfonic acid resin dispersion;

[0037] (2) Catalyst slurry preparation

[0038] Weigh 0.5g of 60%Pt / C catalyst, 1.0g of 20wt.% perfluorosulfonic acid resin dispersion prepared in step (1), 7g of propionic acid, 1g of propanol, and 1.5g of water, mix and ultrasonically stir for 30min to prepare Catalyst slurry.

Embodiment 3

[0040] A preparation method for a catalyst slurry for a proton exchange membrane fuel cell, comprising the following steps:

[0041] (1) Preparation of 5wt.% sulfonated trifluorostyrene resin dispersion

[0042] Mix 5wt.% sulfonated trifluorostyrene resin, 45wt.% water and 50wt.% alcohol, put the mixture into a high-pressure reactor and seal it, pressurize to 6bar, heat to 150°C, and stir for 5 hours. Cooling obtains 5wt.% sulfonated trifluorostyrene resin dispersion;

[0043] (2) Catalyst slurry preparation

[0044] Weigh 0.5g of 60%Pt / C catalyst, 3g of 5% sulfonated trifluorostyrene resin solution prepared in step (1), 6g of oxalic acid, and 1g of isobutanol, mix and ultrasonically stir for 30min to prepare catalyst slurry .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com