Ruthenium-carbon catalyst, and preparation method and application thereof

A ruthenium-carbon catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of large catalyst consumption, high reaction pressure, and high temperature , to achieve the effect of novel preparation method, high conversion rate and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

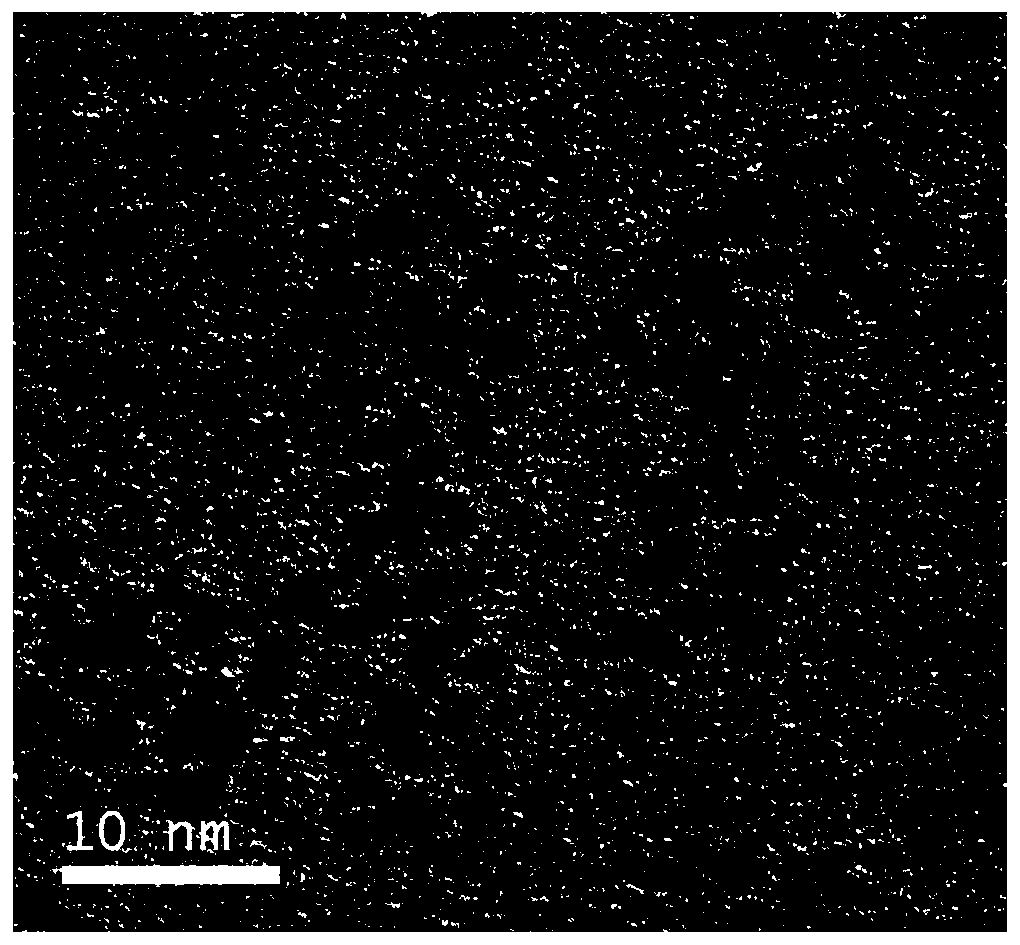

Image

Examples

Embodiment 1

[0028] (1) Preparation of catalyst

[0029] a. Activated carbon is pretreated to obtain carrier activated carbon

[0030] Get 5g gac, it is submerged in 30ml, 3mol / L nitric acid solution (the nitric acid solution preparation method is: the concentrated nitric acid that commercially available mass fraction is 68% and water are mixed together according to the volume ratio of 1:6.41, configure into a dilute nitric acid solution with a required concentration of 3mol / L, the following examples are the same as above), stirred and impregnated for 12 hours at 30°C, filtered, and the filter cake was washed with deionized water for 10 to 20 times until the pH of the filtrate was 7, and then in a tube furnace in N 2 Under the protection of the atmosphere, calcined at 600°C for 4 hours to obtain 4.5 g of carrier activated carbon;

[0031] b. Preparation of Ru nanoparticles

[0032] Take 5.0005×10 -4 mol RuCl 3 ·3H 2 O was dissolved in 150ml propylene carbonate ester, and ultrasonicat...

Embodiment 2

[0039] (1) Preparation of catalyst

[0040] a. Activated carbon is pretreated to obtain carrier activated carbon

[0041] Take 5g of activated carbon, immerse it in 30ml, 3mol / L nitric acid solution, stir and impregnate at 30°C for 12h, filter, wash the filter cake with deionized water for 10 to 20 times until the pH of the filtrate is 7, and then place it in a tube furnace N 2 Under the protection of the atmosphere, calcined at 600°C for 4 hours to obtain 4.5 g of carrier activated carbon;

[0042] b. Preparation of Ru nanoparticles

[0043] Take 5.0005×10 -4 mol RuCl 3 ·3H 2 O was dissolved in 150ml propylene carbonate ester, and ultrasonicated at a frequency of 25KHz for 60min to obtain a concentration of 3.3333×10 -3 mol / L ruthenium chloride solution, and then the above solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and reduced for 6 hours at 60°C under a hydrogen pressure of 4.0MPa to prepare 150ml of Ru nanoparticle solution....

Embodiment 3

[0049] (1) Preparation of catalyst

[0050] a. Activated carbon is pretreated to obtain carrier activated carbon

[0051] Take 5g of activated carbon, immerse it in 30ml, 3mol / L nitric acid solution, stir and impregnate at 30°C for 12h, filter, wash the filter cake with deionized water for 10 to 20 times until the pH of the filtrate is 7, and then place it in a tube furnace N 2 Under the protection of the atmosphere, calcined at 600°C for 4 hours to obtain 4.5 g of carrier activated carbon;

[0052] b. Preparation of Ru nanoparticles

[0053] Take 5.0005×10 -4 mol RuCl 3 ·3H 2 O was dissolved in 150ml propylene carbonate ester, and ultrasonicated at a frequency of 25KHz for 60min to obtain a concentration of 3.3333×10 -3 mol / L ruthenium chloride solution, and then the above solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and reduced for 6 hours at 80°C under a hydrogen pressure of 4.0MPa to prepare 150ml of Ru nanoparticle solution....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com