Double-arc auxiliary laser welding device and method

A technology of welding device and laser device, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of fine grain in weld structure, high welding penetration ratio, unfavorable metal spreading, etc., and achieve the reduction of molten pool Effects of cooling rate, increased welding speed, and improved wettability and spreadability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

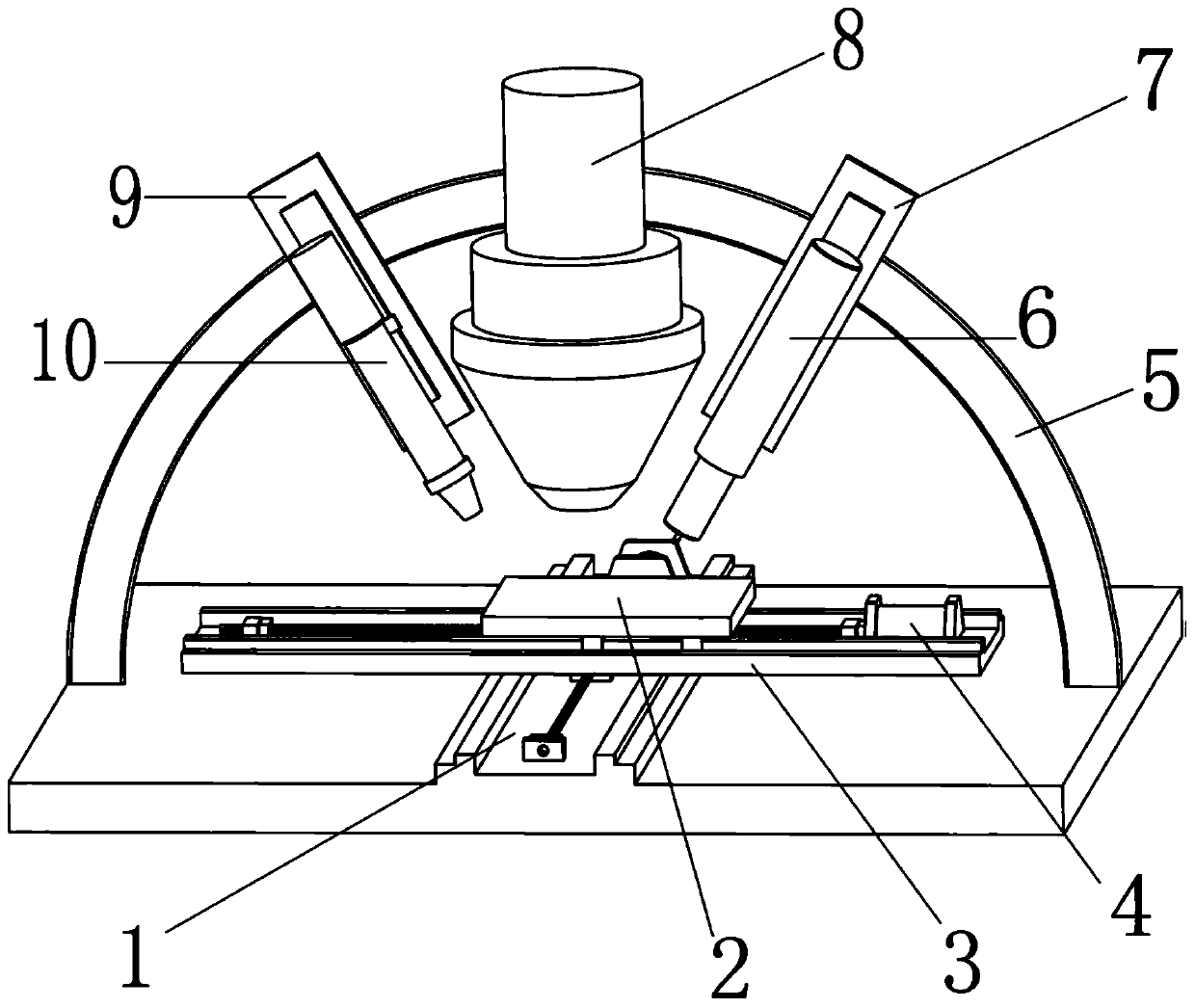

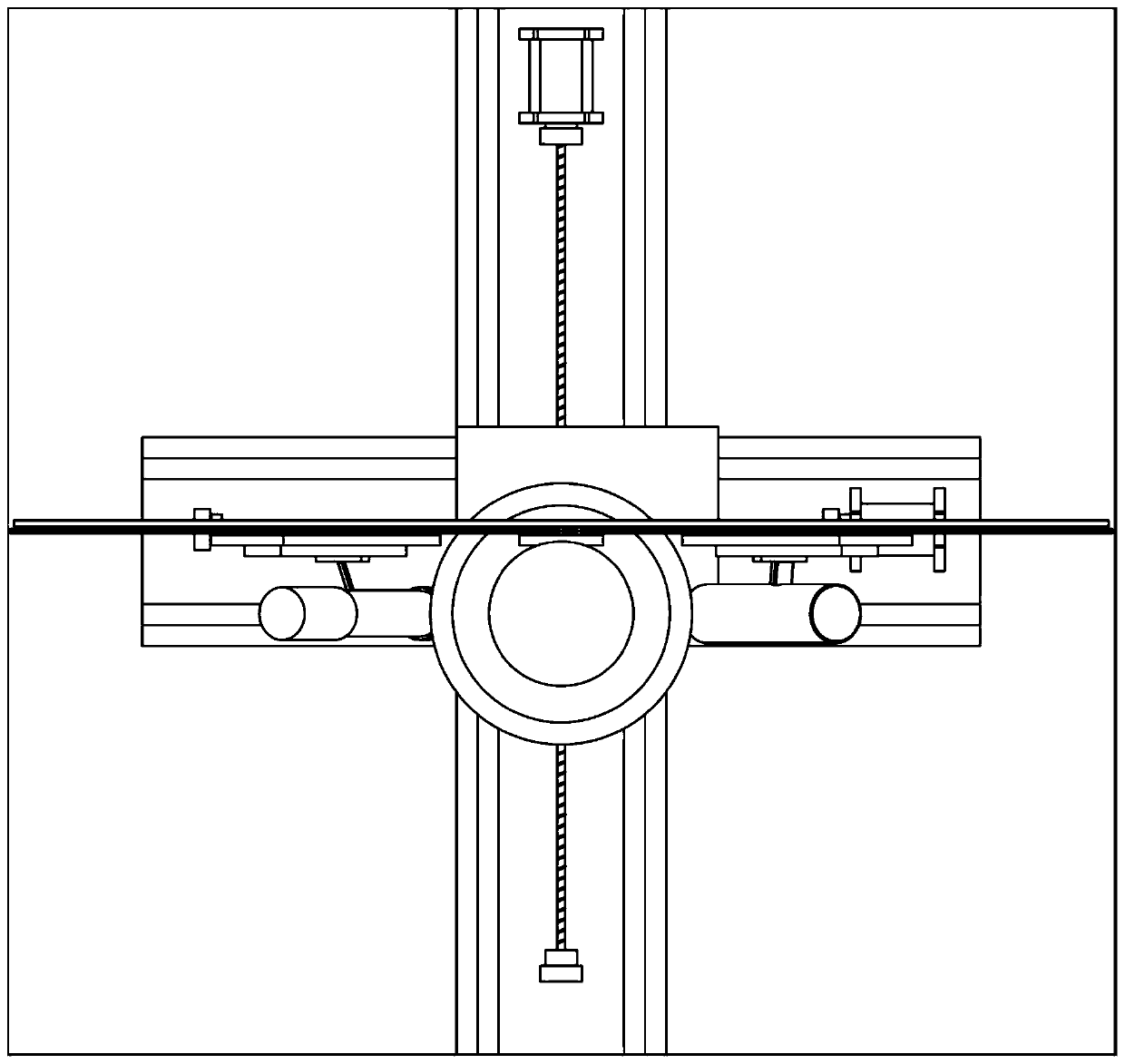

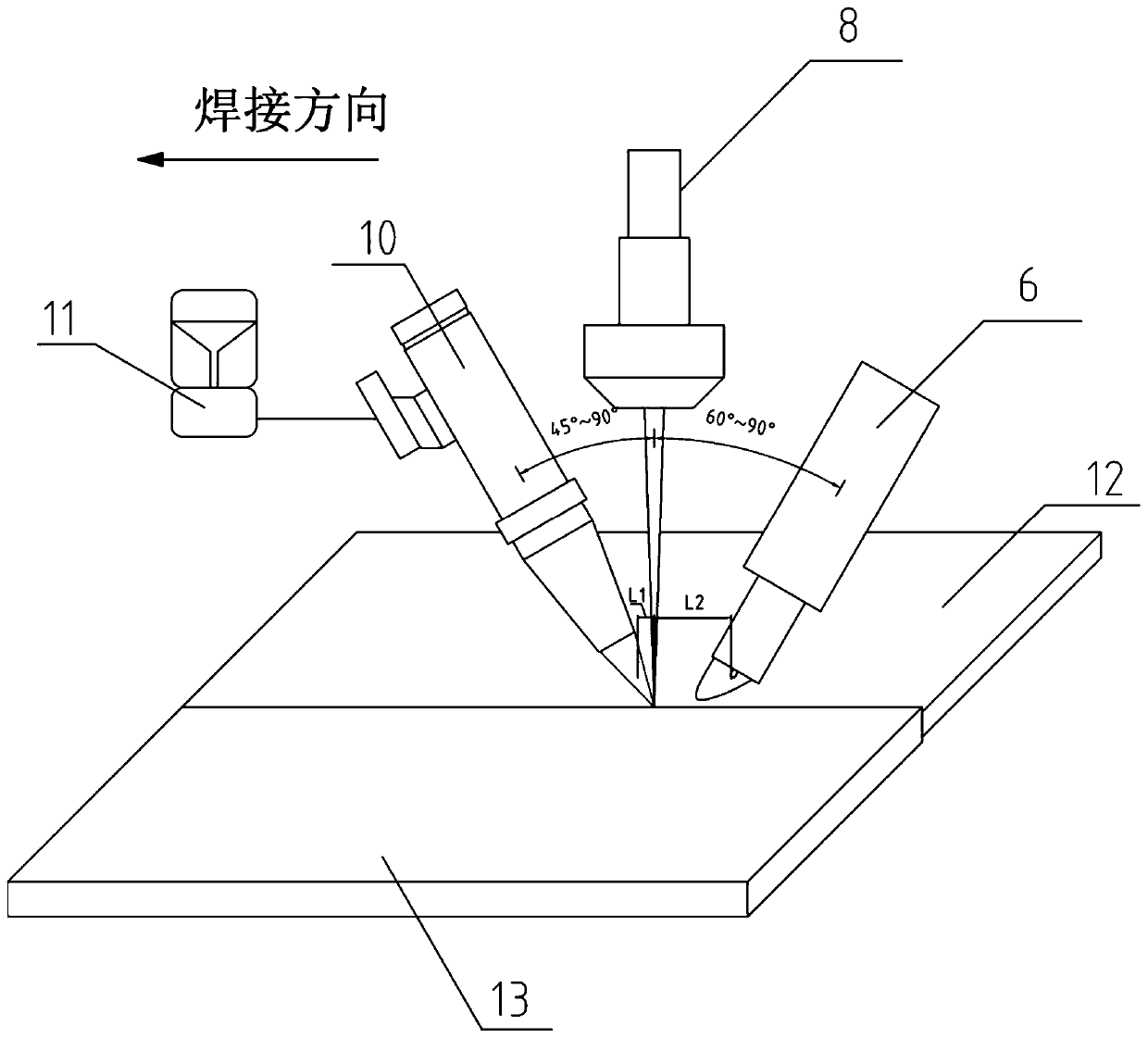

[0035] Such as figure 1 , figure 2 shown, combined with image 3 As shown, this embodiment provides a dual-arc assisted laser welding device, including: Y-axis sliding guide rail 1, welding table 2, X-axis sliding guide rail 3, stepping motor 4, annular sliding guide rail 5, TIG welding device 6, TIG welding sliding guide rail 7, laser device 8, plasma arc welding torch guide rail 9, plasma arc welding device 10 and coaxial powder feeding device 11;

[0036] In this embodiment, the laser device 8, the plasma arc welding device 10 and the TIG welding device 6 are fixedly arranged on the corresponding preset positions of the circular guide rail, and the microcomputer system controls the stepper motor to drive the two-way screw to move through the pre-designed path , the two-way screw adjusts the movement of the Y-axis sliding guide rail 1 and the X-axis sliding guide rail 3, and then controls the movement of the welding table 2, and the double-arc assisted laser welding devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com