Method for rapidly preparing carbon-oxygen co-doped boron nitride room-temperature phosphorescent material through microwave heating

A room temperature phosphorescence and microwave heating technology, applied in the directions of luminescent materials, chemical instruments and methods, etc., can solve the problems of limited types of room temperature phosphorescence materials, unfavorable afterglow visual observation, limited material quality preparation, etc., to achieve excellent room temperature phosphorescence performance, easy to batch Chemical production, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for rapidly preparing a carbon-oxygen co-doped boron nitride room temperature phosphorescent material by microwave heating, comprising the following steps:

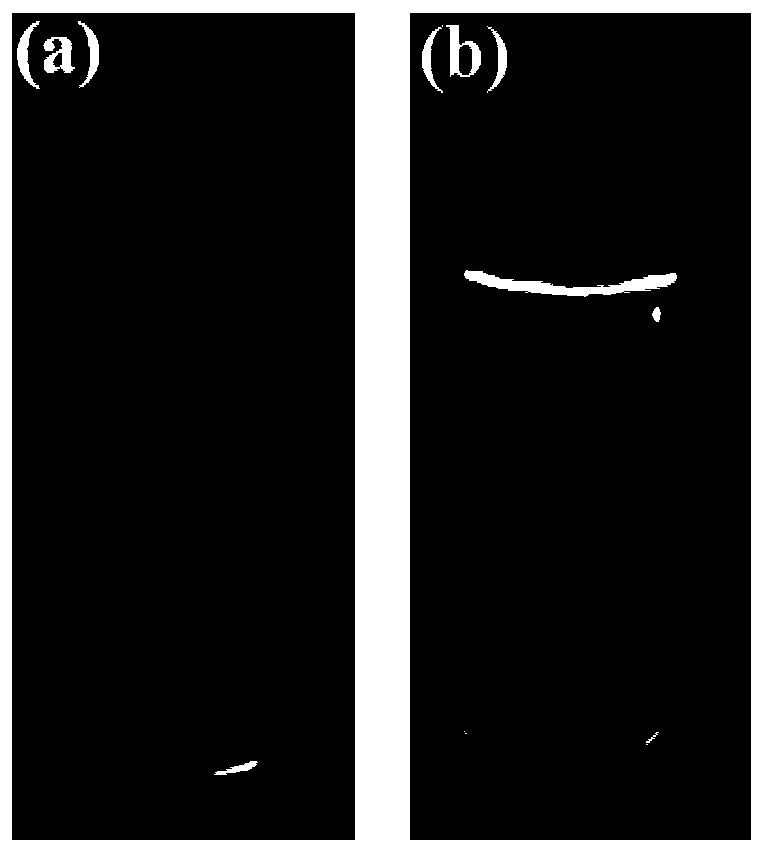

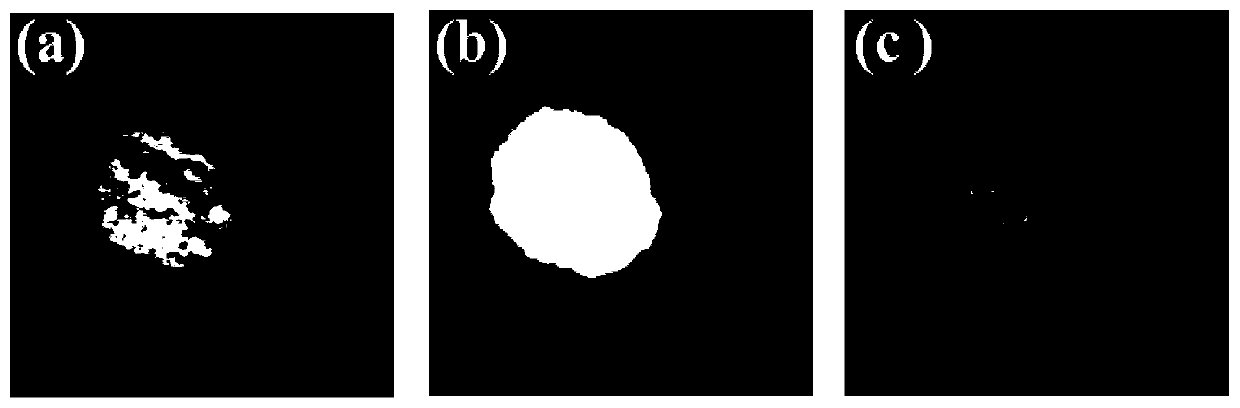

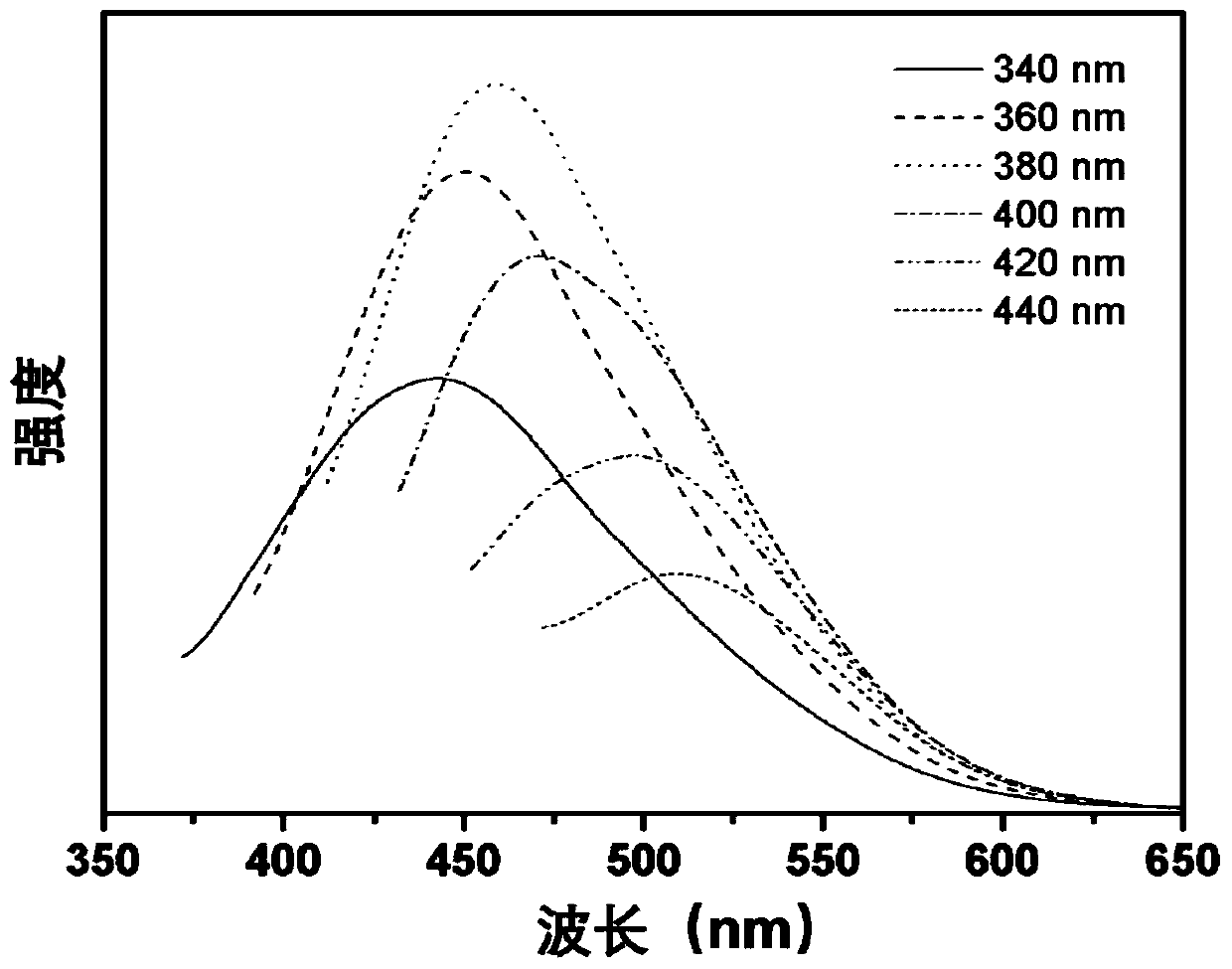

[0038] 0.618 g of boric acid was dissolved in 10 mL of deionized water, and stirred magnetically for 30 minutes to obtain a uniform solution; 0.30 g of ethylenediamine was added thereto, and stirred magnetically for 30 minutes to obtain a mixed solution. The mixed solution was transferred to a microwave oven, and reacted for 15 minutes under the power condition of 700W, and naturally cooled to room temperature after the reaction was completed. Add 80 mL of ethanol to the obtained product, sonicate it for 10 min, then centrifuge it at 10,000 rpm for 10 min to obtain a precipitate, repeat washing 5 times, and vacuum dry the washed product at 80°C for 12 h to obtain a carbon-oxygen co-doped nitride Boron room temperature phosphorescent material.

[0039] Dissolve the carbon-oxygen co-doped boron nitride room...

Embodiment 2

[0049] A method for rapidly preparing a carbon-oxygen co-doped boron nitride room temperature phosphorescent material by microwave heating, comprising the following steps:

[0050] 0.618 g of boric acid was dissolved in 10 mL of deionized water, and stirred magnetically for 30 minutes to obtain a uniform solution; 0.612 g of ethanolamine was added thereto, and stirred magnetically for 30 minutes to obtain a mixed solution. The mixed solution was transferred to a microwave oven, and reacted for 15 minutes under the power condition of 700W, and naturally cooled to room temperature after the reaction was completed. Add 80 mL of ethanol to the obtained product, sonicate it for 10 min, then centrifuge it at 10,000 rpm for 10 min to obtain a precipitate, repeat washing 5 times, and vacuum dry the washed product at 80°C for 12 h to obtain a carbon-oxygen co-doped nitride Boron room temperature phosphorescent material.

Embodiment 3

[0052] A method for rapidly preparing a carbon-oxygen co-doped boron nitride room temperature phosphorescent material by microwave heating, comprising the following steps:

[0053] 0.618g of boric acid was dissolved in 10mL of deionized water, and magnetically stirred for 30 minutes to obtain a uniform solution; 1.055g of diethanolamine was added thereto, and magnetically stirred for 30 minutes to obtain a mixed solution. The mixed solution was transferred to a microwave oven, and reacted for 15 minutes under the power condition of 700W, and naturally cooled to room temperature after the reaction was completed. Add 80 mL of ethanol to the obtained product, sonicate it for 10 min, then centrifuge it at 10,000 rpm for 10 min to obtain a precipitate, repeat washing 5 times, and vacuum dry the washed product at 80°C for 12 h to obtain a carbon-oxygen co-doped nitride Boron room temperature phosphorescent material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com