Extraction device and technology of selenium polypeptide from soybeans

An extraction device and process technology, which is applied in the field of extraction devices for extracting selenium polypeptides, can solve the problems of low efficiency and poor quality of selenium polypeptides, and achieve the effect of solving numerous extraction procedures, less impurities and high purity of selenium polypeptides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

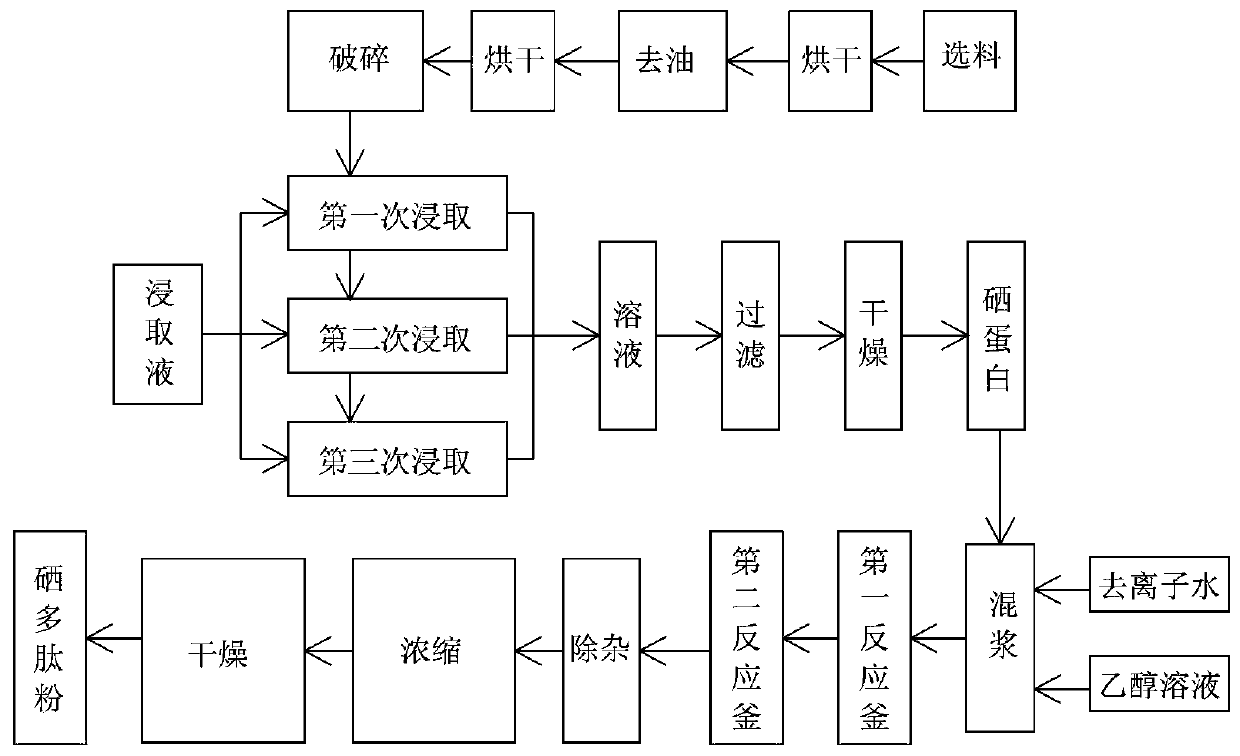

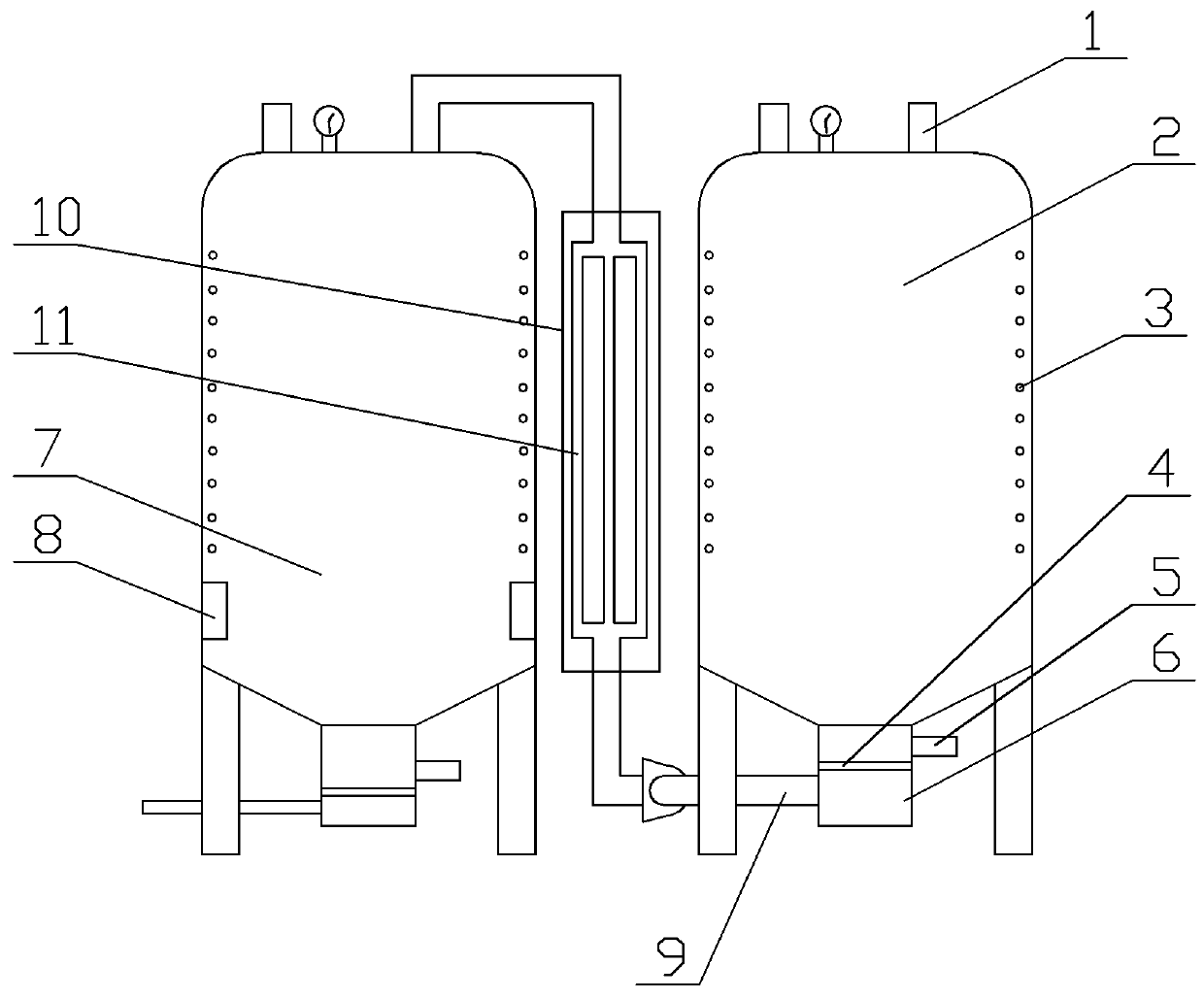

[0028] Embodiment 1: According to figure 1 , an extraction device and process for extracting selenopolypeptides from soybeans, comprising: step 1) preparing materials, step 2) extracting selenoprotein powder, step 3) mixing slurry, step 4) ultrasonic enzymolysis, step 5) modifying, Step 6) removing impurities, and step 7) concentrating and drying.

[0029] Described process comprises the following steps:

[0030] 1) Prepare materials, select mature soybeans rich in selenium, pass through a vibrating sieve to remove sand and stones, dry to remove the outer skin, and remove oil. The oil content of soybean meal after oil removal is less than 3%, and crushed into soybean powder with a size of 80 mesh;

[0031] 2) To extract protein, mix soybean powder with water at a solid-to-liquid weight ratio of 1:20-25, adjust the Ph value to 9.5 by adding sodium hydroxide solution, and leaching for 5 hours at a temperature of 45-60°C. Slowly stir in the medium, and after the leaching is com...

Embodiment 2

[0044] Embodiment 2, described membrane filtration adopts twice to filter, adopts membrane hole to be 50-300 μm microporous membrane for the first time, filter out macromolecular protein, adopts membrane hole to be less than 15 μm microporous membrane for the second time, intercepts small Molecular peptides, filtering out smaller amino acids.

[0045] In addition to filtering out large molecular proteins, smaller amino acid molecules are also filtered out to increase the purity of peptides.

Embodiment 3

[0046] Embodiment 3, described technique comprises the following steps:

[0047] 1) Prepare materials, select mature soybeans rich in selenium, pass through a vibrating sieve to remove sand and stones, dry to remove the outer skin, and remove oil. The oil content of soybean meal after oil removal is less than 3%, and crushed into soybean powder with a size of 80 mesh;

[0048] 2) To extract protein, mix soybean powder with water at a solid-to-liquid weight ratio of 1:20, adjust the Ph value to 9.5 by adding sodium hydroxide solution, and leaching for 5 hours at a leaching temperature of 60°C, stirring during leaching , stirred at 40 rpm, and after the leaching was completed, solid-liquid filtration and separation were carried out;

[0049] Secondary leaching: carry out secondary leaching on the leached slag, mix soybean powder with water at a solid-to-liquid weight ratio of 1:15, adjust the Ph value to 9.5 by adding sodium hydroxide solution, and leaching for 3 hours , the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com