Regenerated cellulose fiber containing shea butter, and preparation method thereof

A technology of regenerated cellulose and shea butter, applied in the textile field, can solve the problems of non-applicable anti-fabric, etc., and achieve the effect of improving moisturizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

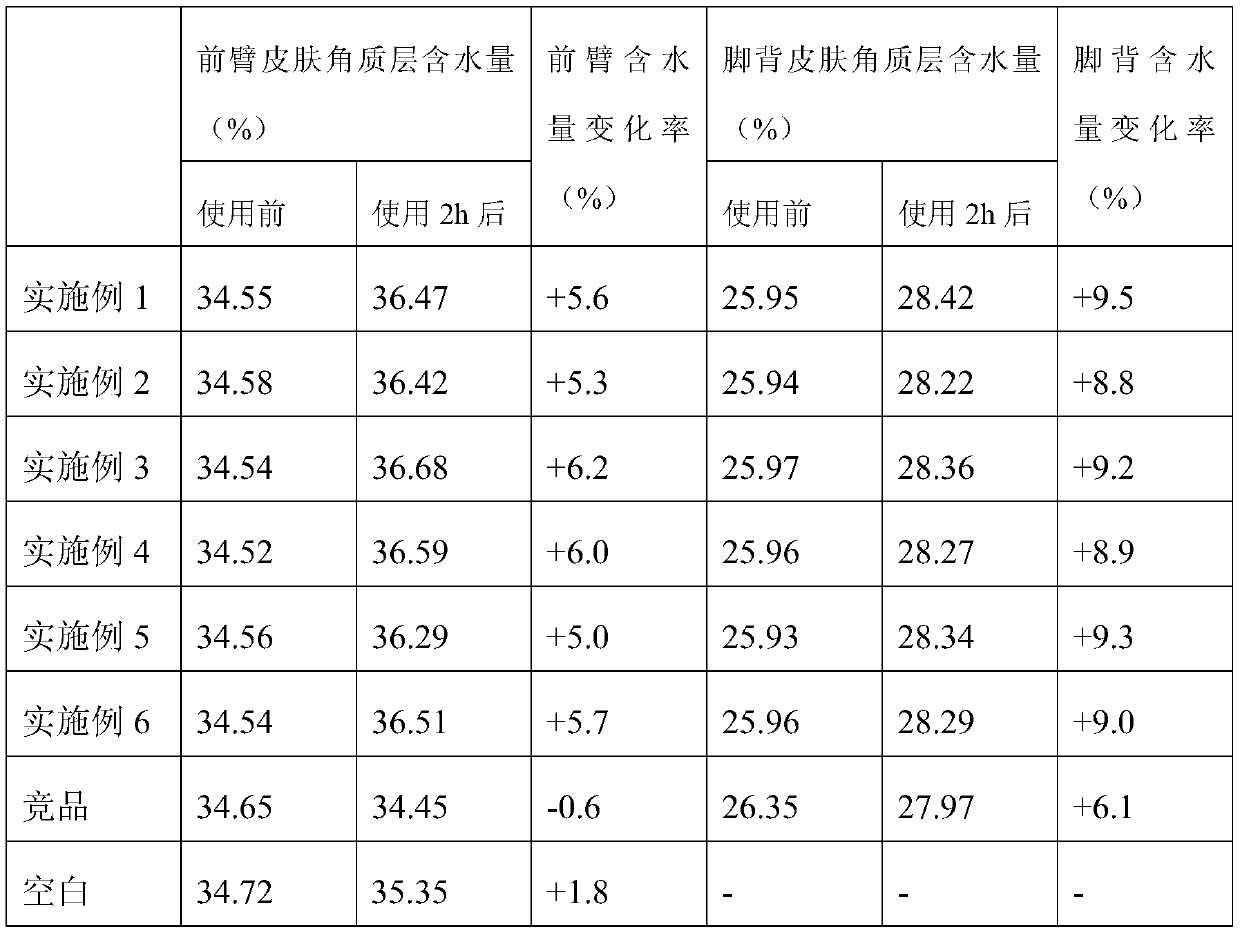

Examples

Embodiment 1

[0044] Fibers were prepared as follows:

[0045] (1) The emulsification includes adding shea butter to the emulsifier, heating up to 35° C., and stirring at 3500 rpm for 30 min to obtain a shea butter emulsion; the mass ratio of the shea butter to the emulsifier is 1:0.5, the emulsifier is a mixture of polyethoxylated isotridecanol and Tween 80, and the mass ratio of polyethoxylated isotridecyl alcohol to Tween 80 is 0.3:1;

[0046] (2) Mix a certain proportion of melamine and formaldehyde, add deionized water to stir and adjust the pH to 8.0, slowly raise the temperature to 65°C, and stir at 1000rpm for 30min to obtain a prepolymer;

[0047] (3) Add the prepolymer prepared in step (2) dropwise to the shea butter emulsion prepared in step (1), while applying stirring with a rotating speed of 1300rpm, while adjusting the temperature to 60°C and adjusting the pH to 6.0, stir for 2 hours, add sodium methylene bis-naphthalene sulfonate to obtain microcapsule liquid;

[0048] (4)...

Embodiment 2

[0053] Fibers were prepared as follows:

[0054] (1) The emulsification includes adding shea butter to the emulsifier, heating up to 52° C., and stirring at 3100 rpm for 10 min to obtain a shea butter emulsion; the mass ratio of the shea butter to the emulsifier is 1:0.4, the emulsifier is a mixture of polyethoxylated isotridecanol and Tween 80, and the mass ratio of polyethoxylated isotridecyl alcohol to Tween 80 is 0.4:1;

[0055] (2) Mix a certain proportion of melamine and formaldehyde, add deionized water to stir and adjust the pH to 7.8, slowly raise the temperature to 65°C, and stir at a speed of 900rpm for 30min to obtain a prepolymer;

[0056] (3) Add the prepolymer prepared in step (2) dropwise to the shea butter emulsion prepared in step (1), while applying stirring with a rotating speed of 1300rpm, while adjusting the temperature to 60°C and adjusting the pH to 4.5, stir for 1 hour, add sodium methylene bis-naphthalene sulfonate to obtain microcapsule liquid;

[...

Embodiment 3

[0062] Fibers were prepared as follows:

[0063] (1) The emulsification includes adding shea butter to the emulsifier, heating up to 45° C., and stirring at 3000 rpm for 20 min to obtain a shea butter emulsion; the mass ratio of the shea butter to the emulsifier is 1:0.5, the emulsifier is a mixture of polyethoxylated isotridecanol and Tween 80, and the mass ratio of polyethoxylated isotridecyl alcohol to Tween 80 is 0.5:1;

[0064] (2) Mix a certain proportion of melamine and formaldehyde, add deionized water to stir and adjust the pH to 8.2, slowly raise the temperature to 65°C, and stir at 800rpm for 30min to obtain a prepolymer;

[0065] (3) Add the prepolymer prepared in step (2) dropwise to the shea butter emulsion prepared in step (1), while applying stirring at a speed of 1500 rpm, while adjusting the temperature to 60°C and adjusting the pH to 5. Stir for 30 minutes, add sodium methylene bis-naphthalene sulfonate to obtain microcapsule liquid;

[0066] (4) butylmeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com