Zero-opening light-tight polymer composite sun-shading fabric and preparation process thereof

A polymer and fabric technology, applied in fabric surface trimming, weaving, woven fabrics, etc., to achieve the effect of good self-cleaning, stable room temperature, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

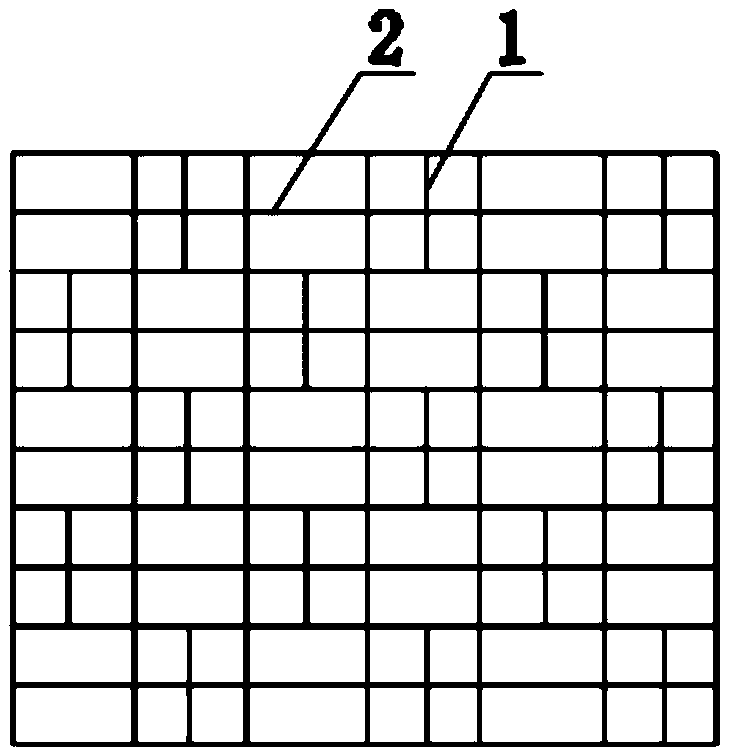

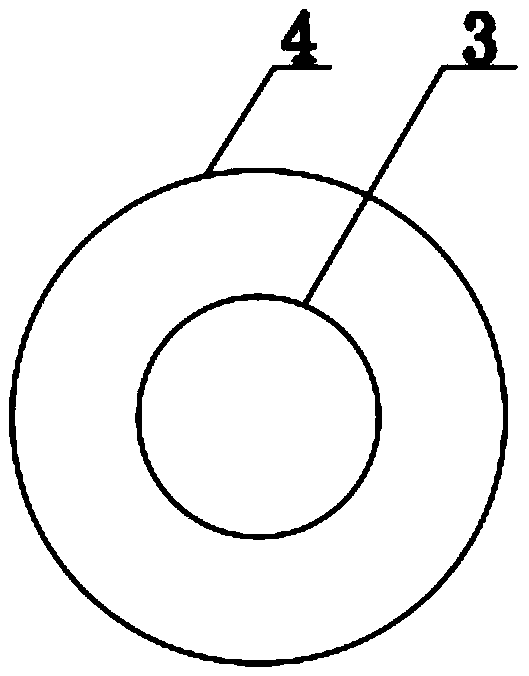

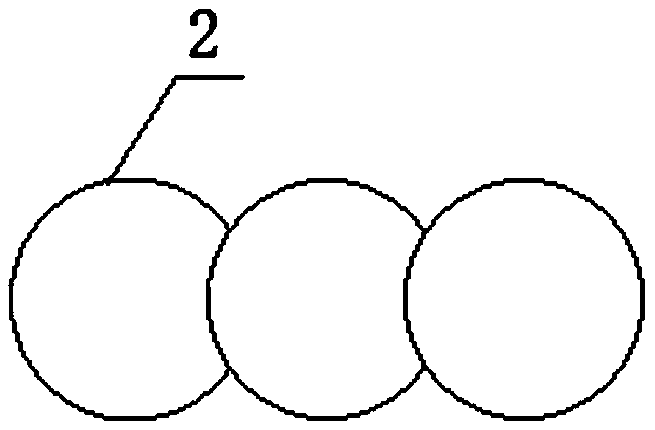

[0032] Embodiment 1, a polymer composite sunshade fabric with zero openings and light-tightness, including warp yarns and weft yarns used to weave a fabric with a tight and void-free structure, the warp yarns include a warp core, and the warp core is coated on the outside of the warp core The warp yarn elastic coating layer, the weft yarn includes a weft core, and the weft yarn elastic coating layer coated on the outside of the weft core, the warp yarn diameter is 0.3mm, the weft yarn diameter is 0.2mm, and the weft yarn diameter is 0.2mm. The density is 16 strands / cm, the thickness of the warp elastic covering layer is 0.065mm, the thickness of the weft elastic covering layer is 0.013mm, and the warp elastic covering layer and the weft elastic covering layer both include a polymer with a degree of polymerization of 1000 80 parts of polyvinyl chloride resin powder, 3.2 parts of matting polyvinyl chloride resin powder, 0.1 part of ultraviolet absorber, 0.08 part of toner, and th...

Embodiment 2

[0048] Embodiment 2, a polymer composite sunshade fabric with zero openings and light-tightness, including warp yarns and weft yarns for weaving to form a fabric with a tight and void-free structure, the warp yarns include a warp core, and a warp core is coated on the outside of the warp core The warp yarn elastic coating layer, the weft yarn includes a weft core, and the weft yarn elastic coating layer coated on the outside of the weft core, the warp yarn diameter is 0.4mm, the weft yarn diameter is 0.3mm, and the weft yarn diameter is 0.3mm. The density is 18 threads / cm, the thickness of the warp elastic coating layer is 0.2mm, and the weft elastic coating layer thickness is 0.15mm. 100 parts of polyvinyl chloride resin powder, 6 parts of matting polyvinyl chloride resin powder, 2 parts of ultraviolet absorber, 15 parts of toner, and the balance is auxiliary agent.

[0049] The auxiliary agent includes 20 parts of plasticizer, 5 parts of cold-resistant plasticizer, 5 parts o...

Embodiment 3

[0065] Embodiment 3, a polymer composite sunshade fabric with zero openings and light-tightness, including warp yarns and weft yarns used to weave a fabric with a tight and void-free structure, the warp yarns include a warp core, and a warp core is coated on the outside of the warp core The warp yarn elastic coating layer, the weft yarn includes a weft core, and the weft yarn elastic coating layer coated on the outside of the weft core, the warp yarn diameter is 0.5mm, the weft yarn diameter is 0.4mm, and the weft yarn diameter is 0.4mm. The density is 23 strands / cm, the warp elastic coating layer thickness is 0.28mm, the weft elastic coating layer thickness is 0.18mm, and the warp yarn elastic coating layer and weft yarn elastic coating layer both include the 120 parts of polyvinyl chloride resin powder, 22.6 parts of matting polyvinyl chloride resin powder, 3.3 parts of ultraviolet absorber, 19.7 parts of toner, and the balance is auxiliary agent.

[0066] The auxiliary agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com