Combined heat and power system based on reforming hydrogen production device and fuel cells

A technology for reforming hydrogen production devices and fuel cells, which can be used in fuel cell heat exchange, fuel cells, fuel cell additives, etc. High, avoid power waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

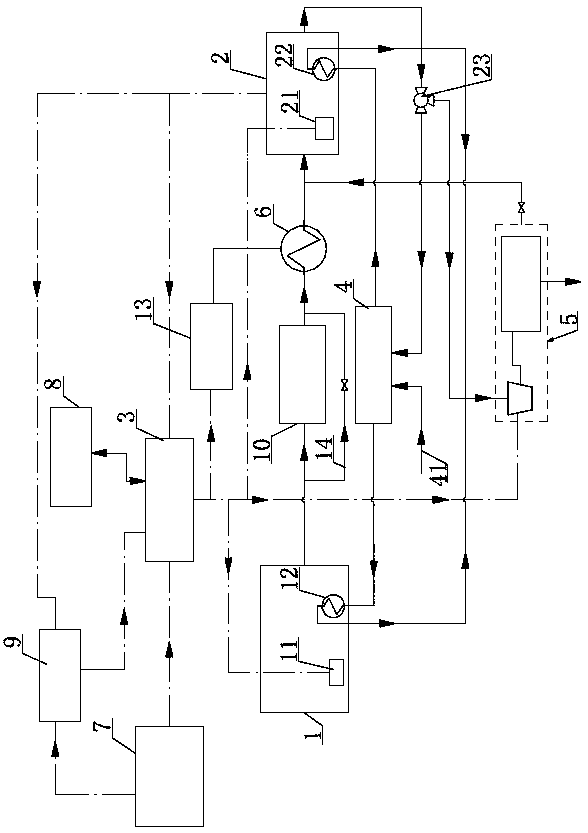

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0021] Such as figure 1 As shown, the combined heat and power system based on reforming hydrogen production device and fuel cell includes: reforming hydrogen production device 1 and fuel cell stack 2, electric energy converter 3, catalytic heater 4, and carbon catcher 5 with compressor And heat supply heat exchanger 6.

[0022] The reforming hydrogen production unit 1 is a device for converting hydrogen-containing compounds into hydrogen-rich reformed gas. The raw materials for reforming hydrogen production can be hydrocarbons such as natural gas, gasoline, diesel, or alcohols such as methanol and alcohol. Due to the incomplete combustion of raw materials, the hydrogen-enriched reformed gas output from the hydrogen output end of the reforming hydrogen production unit 1 also contains a certain amount of CO.

[0023] The fuel cell st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com