Mosquito repellent tablet and preparation method thereof

A mosquito repellent sheet and drying technology are applied in the fields of botanical equipment and methods, pest repellents, animal repellents, etc., can solve the problems of loss of essential oils in the early stage of volatilization and the like, and achieve the preparation method that is simple and easy to operate and the amount of volatilization Even, long-lasting results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

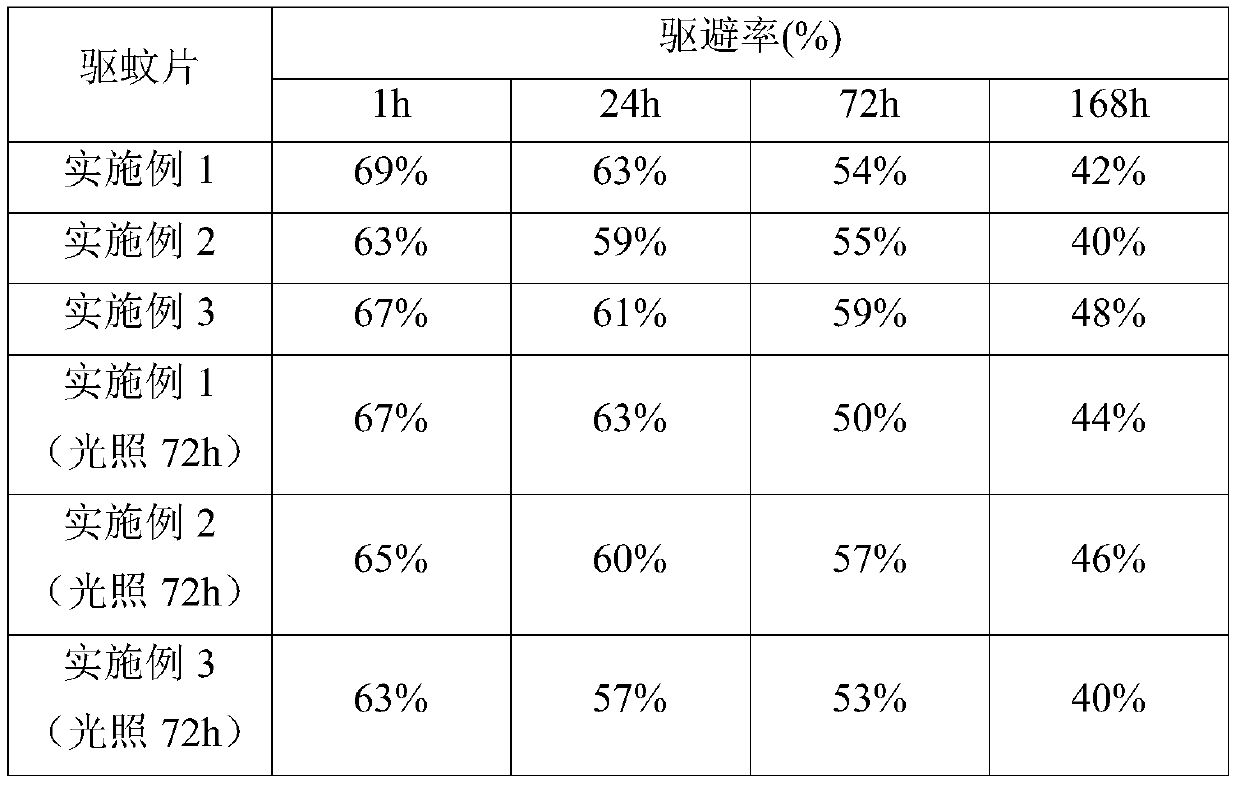

Embodiment 1

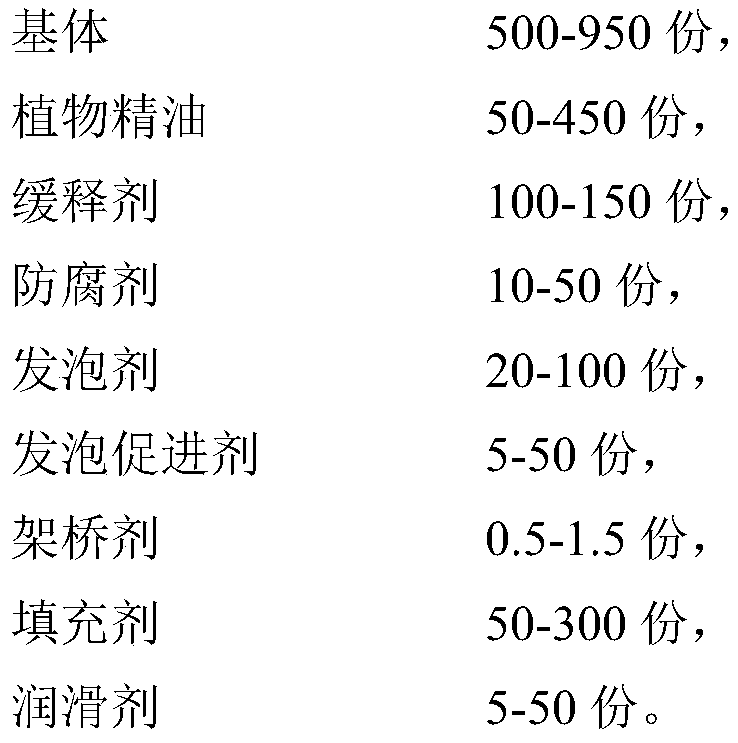

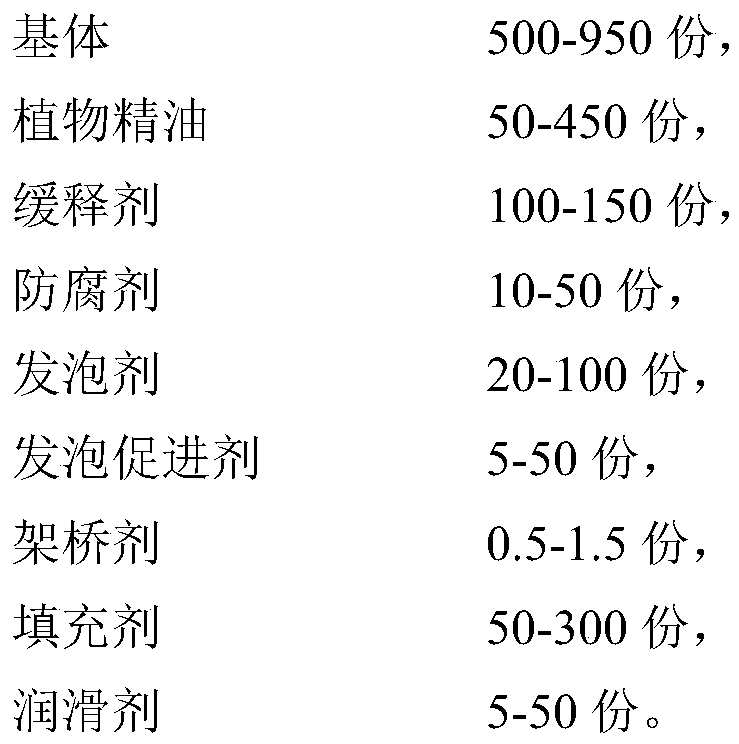

[0025] A mosquito repellent sheet, comprising the following raw materials in parts by weight:

[0026] 600 parts of ethylene-vinyl acetate copolymer, 50 parts of eucalyptus oil, 50 parts of lavender oil, 50 parts of lemon eucalyptus oil, 50 parts of wild chrysanthemum oil, 40 parts of isopropyl myristate, 60 parts of isopropyl palmitate, 2 ,20 parts of 6-di-tert-butyl-4-methylphenol, 2-[2-hydroxy-3,5-bis(1,1-dimethylpropylphenyl)]-2H-benzotriazole 1 30 parts, 30 parts of azodicarbonamide, 10 parts of zinc stearate powder, 1 part of triallyl isocyanurate (TAIC), 200 parts of perlite, 30 parts of stearic acid.

[0027] The preparation method of this mosquito repellent sheet is as follows:

[0028] Mix the above raw materials evenly and dry in an oven at 70°C for 150 minutes to obtain a dry mixture; mix and inject the dried mixture at a temperature of 120°C to obtain the base material of the mosquito repellent sheet; cut the base material of the mosquito repellent sheet Then pu...

Embodiment 2

[0030] A mosquito repellent sheet, comprising the following raw materials in parts by weight:

[0031] 500 parts of silica gel, 50 parts of eucalyptus oil, 50 parts of clove oil, 50 parts of lemon oil, 50 parts of wild chrysanthemum oil, 40 parts of isopropyl myristate, 60 parts of isopropyl palmitate, diisopropyl hexamethylene diester 20 parts, 20 parts of 2,6-di-tert-butyl-4-methylphenol, 2-[2-hydroxy-3,5-bis(1,1-dimethylpropylphenyl)]-2H-benzene 1 part of triazole, 30 parts of azodicarbonamide, 10 parts of zinc stearate powder, 1 part of trimethylolpropane trimethacrylate (PL400), 180 parts of perlite, and 25 parts of stearic acid.

[0032] The preparation method of this mosquito repellent sheet is as follows:

[0033] Mix the above raw materials evenly and dry in an oven at 45°C for 170 minutes to obtain a dry mixture; mix and inject the dried mixture at a temperature of 100°C to obtain the base material of the mosquito repellent sheet; cut the base material of the mosqui...

Embodiment 3

[0035] A mosquito repellent sheet, the difference from the raw materials of Example 1 is that it does not contain isopropyl myristate, and the slow-release agent is 60 parts of isopropyl palmitate, 25 parts of hexamethylene diester diisopropyl ester, acetyl lemon Acetate tri-n-butyl ester 15 parts.

[0036] The preparation method of this mosquito repellent sheet is as follows:

[0037] Mix the above raw materials evenly and dry in an oven at 75°C for 100 minutes to obtain a dry mixture; mix and inject the dried mixture at a temperature of 110°C to obtain the base material of the mosquito repellent sheet; cut the base material of the mosquito repellent sheet Then put it into a flat vulcanizer for hot pressing, the temperature of the hot pressing is 160°C, the pressure is 18Mpa, the time is 15min, the pressure is automatically released, and the mold is cooled to get final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com