Method for determining alternate timing in additive and subtractive composite manufacturing

A technology of adding and subtracting materials and timing, which is applied in the direction of manufacturing tools, automatic control devices, metal processing machinery parts, etc., can solve the problems of inability to guarantee the accessibility of tools, many times of switching between adding and subtracting materials, and low efficiency, so as to shorten the process Make the time, reduce the switching time of adding and subtracting materials, ensure the processing accuracy and the best effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The isometric side view of the specific embodiment of the invention is as attached image 3 As shown in , after pre-identifying the features of the part, it is found that the inner cavity of the part has a large depth-to-width ratio, and contains conical surfaces and curved surface features of various curvatures. way to form.

[0059] The part material of this embodiment is predetermined to be martensitic stainless steel, the laser power is set to 350W, and the scanning speed is 1000mm / s; Figure 4 There are two places in A and B. A is the enlarged diameter, and B is the reduced diameter. The slope of the two contours in the vertical direction changes significantly, so the thickness of the powder layer at A and B should be smaller.

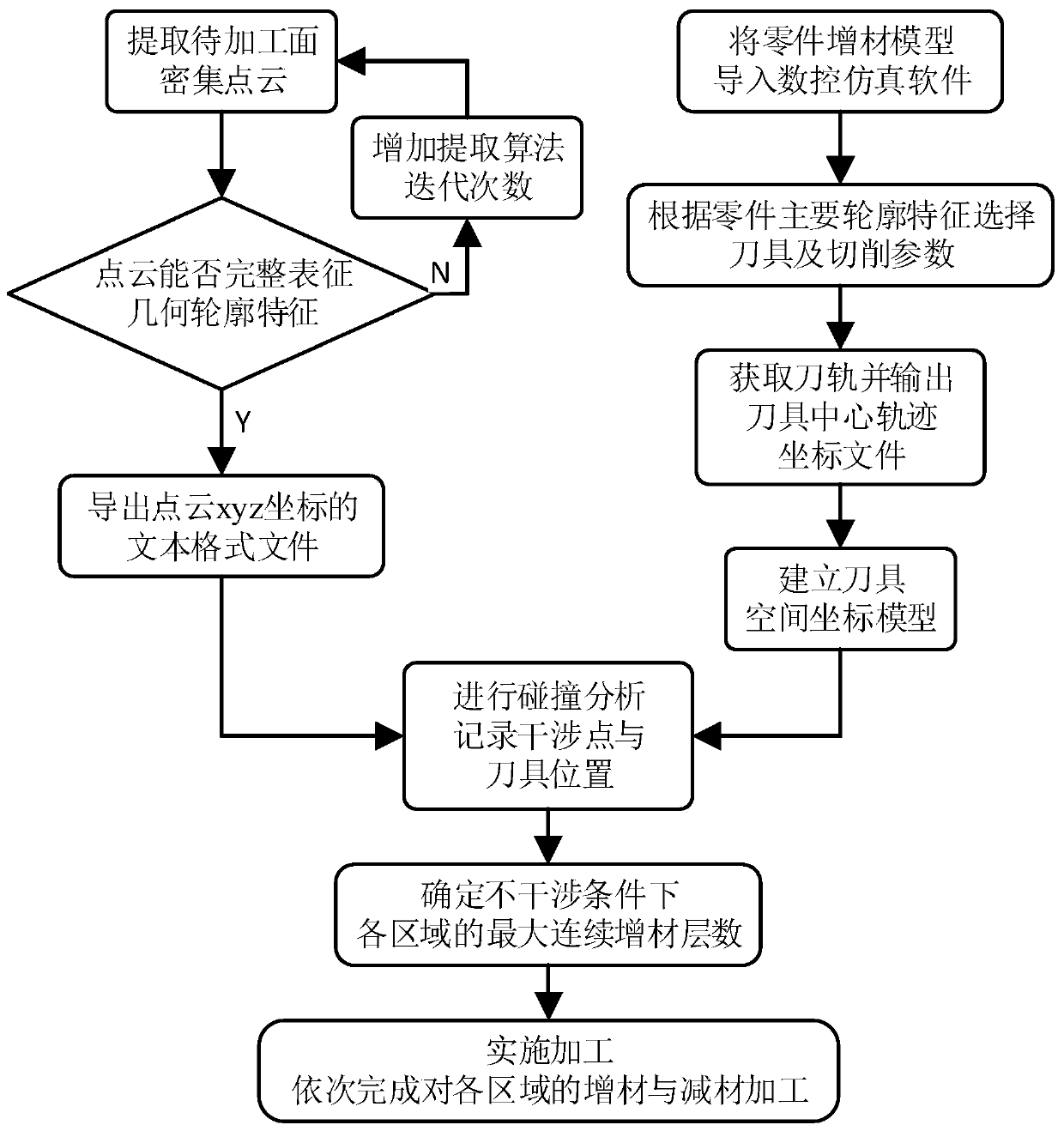

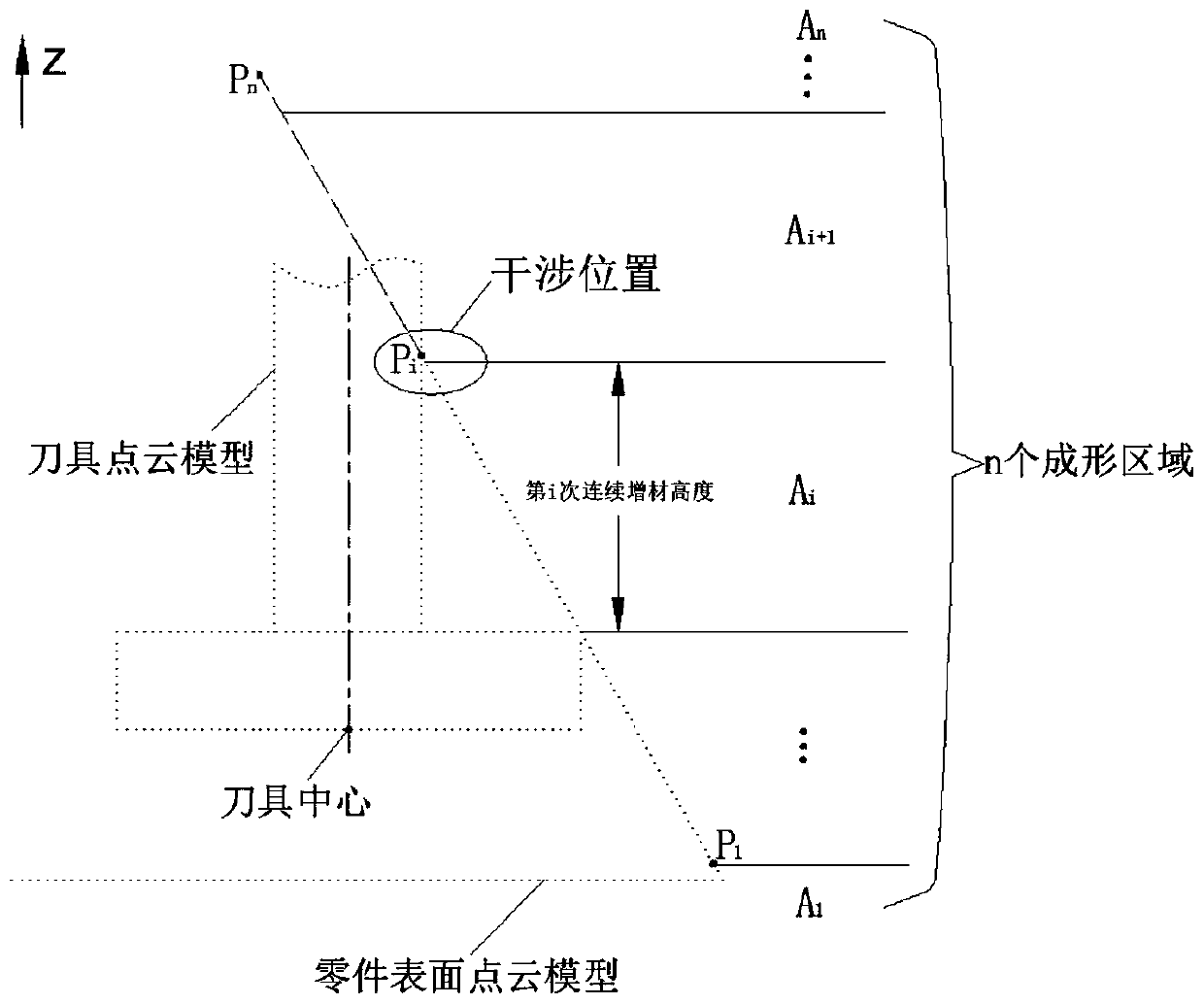

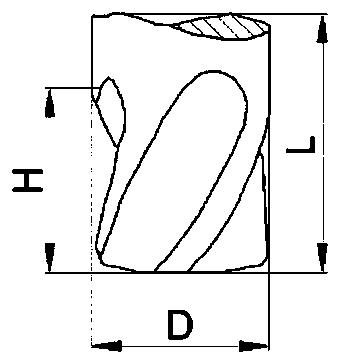

[0060] as attached figure 1 As shown in , first import the 3D model of the part into the NC simulation processing software, and judge that the contour features of the part are mainly slopes and curved surfaces. Figure 5 The forming bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com