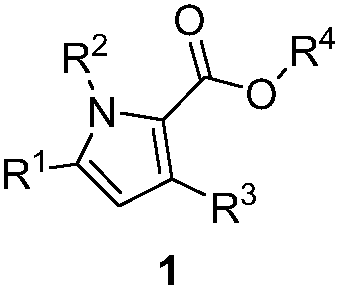

Polysubstituted pyrrole compound and synthesis method thereof

A synthesis method and multi-substitution technology are applied in the field of pyrrole derivatives and synthesis thereof, and achieve the effects of cheap and easy-to-obtain raw materials, regulation of immunity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

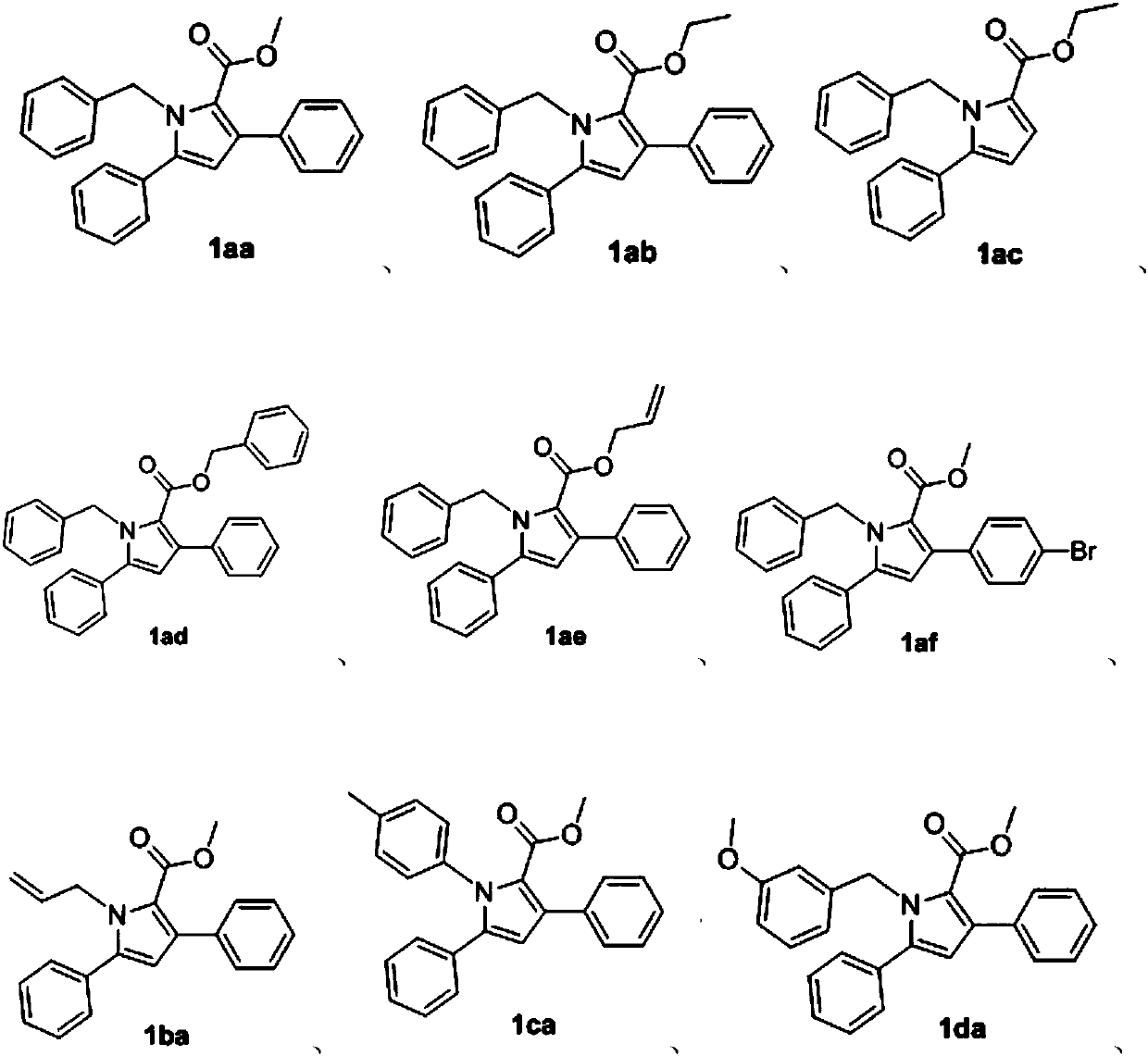

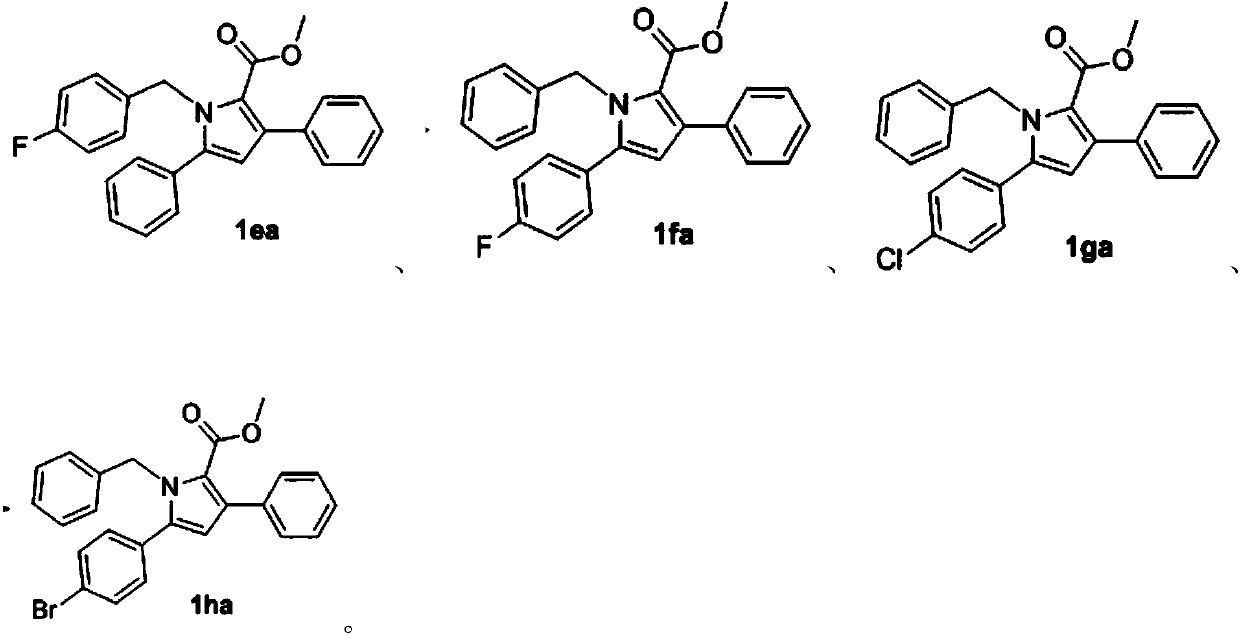

Embodiment 1

[0027]

[0028] Sequentially weigh 1-keto-1-phenyl-3-benzylamino-2-propene 2a (0.5mmol), tetraacetonitrile copper hexafluorophosphate (0.005mmol) in a 25mL Schlenk reaction flask, add 3mL of acetonitrile, at 40 Stir in an oil bath at ℃ for 2 minutes, add α-methyl diazophenylacetate 3a (0.6 mmol), and react for 20 hours. After the reaction, the mixture was cooled to room temperature, extracted with dichloromethane and water, the organic phase was collected, dried over anhydrous sodium sulfate, filtered, and the volatile components were removed under reduced pressure, and then separated by silica gel column chromatography (eluent was petroleum Ether (60-90° C.) / ethyl acetate, v / v=50:1), the target product 1aa was obtained as a colorless oil (110 mg, yield 60%). The target product was confirmed by NMR and high-resolution mass spectrometry.

Embodiment 2

[0030]

[0031] Sequentially weigh 1-keto-1-phenyl-3-benzylamino-2-propene 2a (0.5mmol) and cuprous trifluoromethanesulfonate (0.1mmol) in a 25mL Schlenk reaction flask, add 2mL of DMF, and Stir in an oil bath at 60°C for 2 minutes, add ethyl α-diazophenylacetate 3b (0.7 mmol), and react for 10 hours. After the reaction, the mixture was cooled to room temperature, extracted with dichloromethane and water, the organic phase was collected, dried over anhydrous sodium sulfate, filtered, and the volatile components were removed under reduced pressure, and then separated by silica gel column chromatography (eluent was petroleum Ether (60-90° C.) / ethyl acetate, v / v=50:1) to obtain the target product 1ab (105 mg, yield 55%) as a colorless oil. The target product was confirmed by NMR and high-resolution mass spectrometry.

Embodiment 3

[0033]

[0034] Sequentially weigh 1-keto-1-phenyl-3-benzylamino-2-propene 2a (0.5mmol), copper acetate (0.1mmol) into a 25mL Schlenk reaction flask, add DCE 2mL, and place in an oil bath at 80°C Stir for 2 minutes, add α-ethyl diazoacetate 3c (2.5mmol), and react for 48 hours. After the reaction is over, the mixture is cooled to room temperature, extracted with dichloromethane and water, and the organic phase is collected, dried over anhydrous sodium sulfate, and filtered. The volatile components were removed under reduced pressure, and then separated by silica gel column chromatography (eluent was petroleum ether (60-90°C) / ethyl acetate, v / v=50:1) to obtain the colorless oily target product 1ac ( 61 mg, yield 40%). The target product was confirmed by NMR and high-resolution mass spectrometry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com