Cobalt tetroxide/zinc oxide nanoflower heterojunction film sensitive to acetone

A nano-technology of cobalt tetraoxide and zinc oxide, which is applied in the field of gas sensor, and achieves the effects of low raw material cost, good repeatability and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

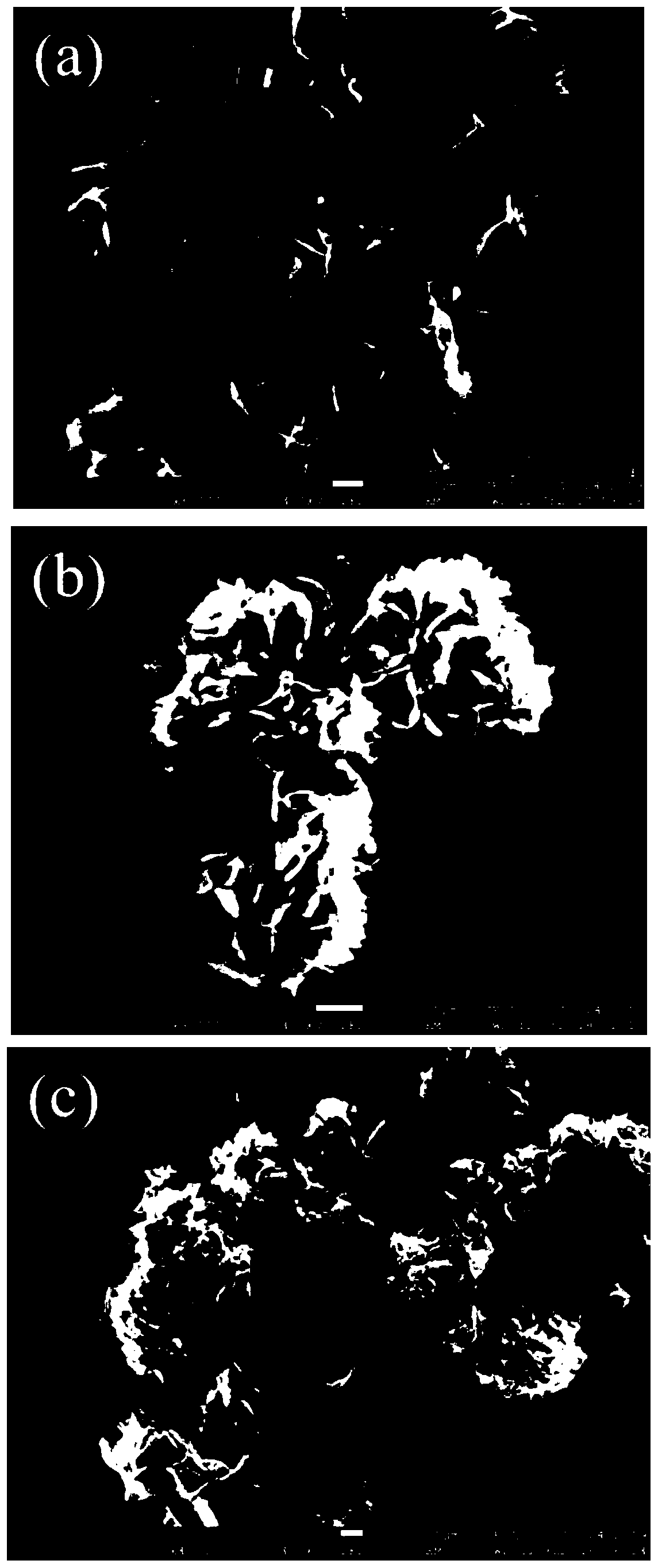

Image

Examples

Embodiment 1

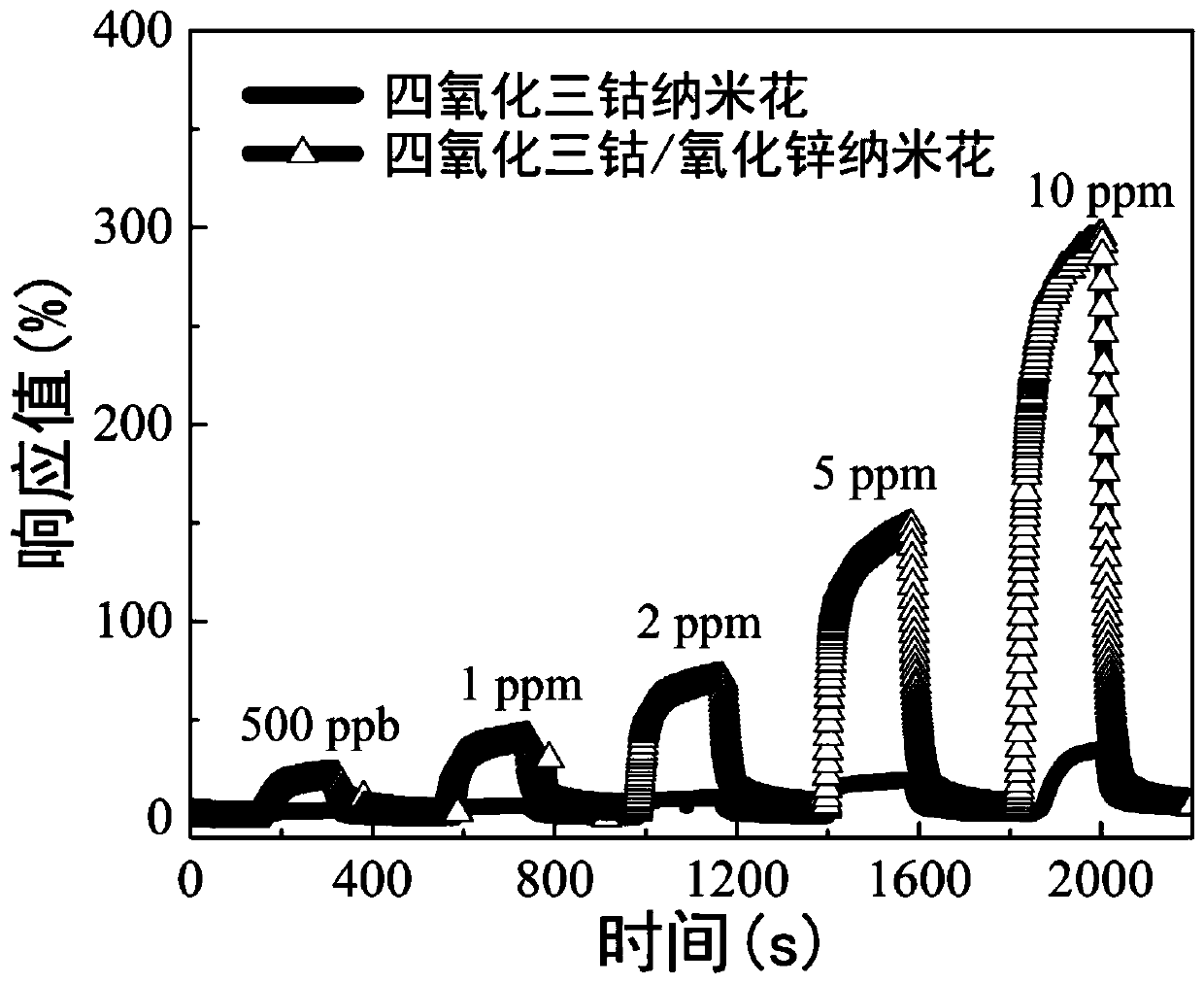

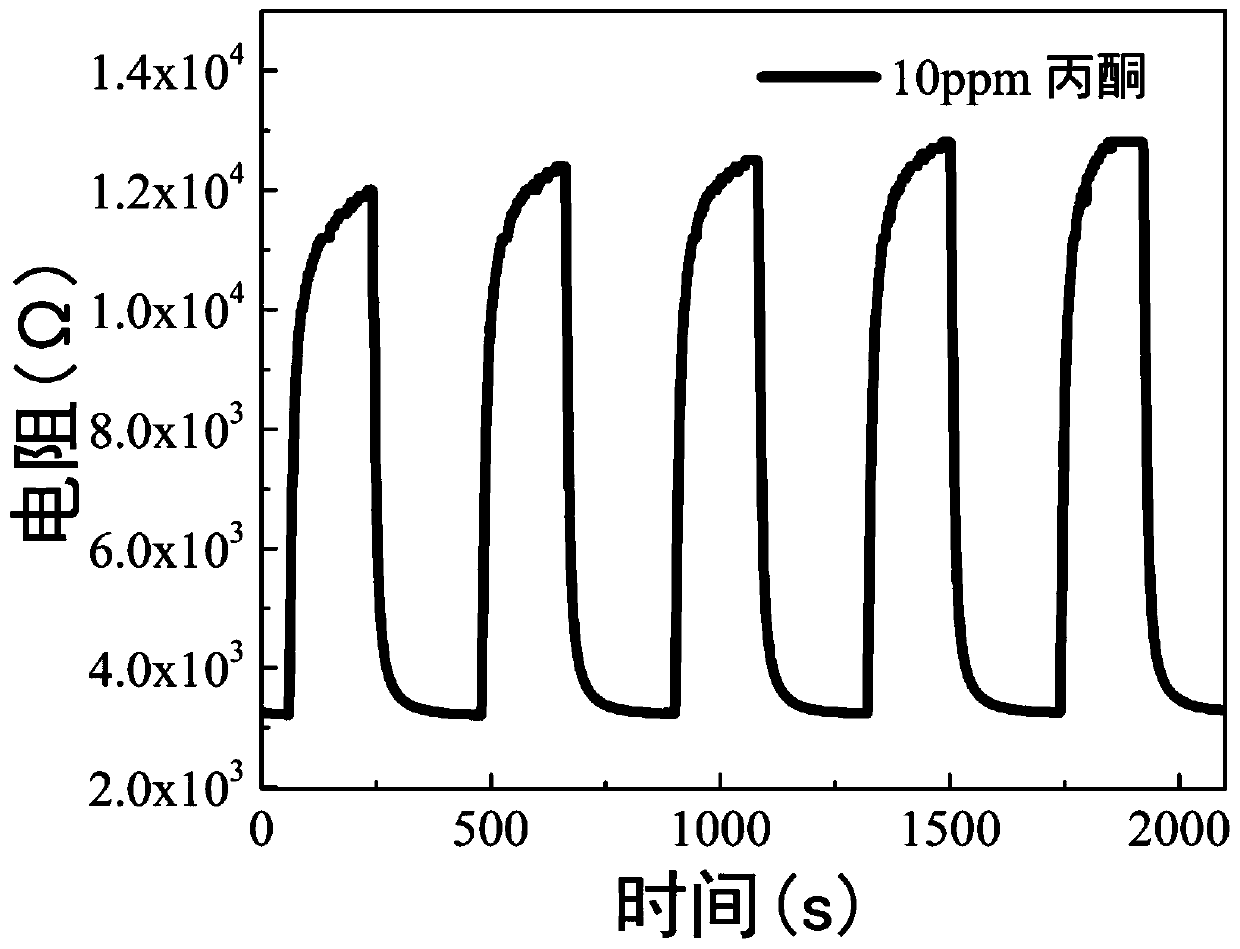

[0021] Example 1, 0.8294 g of cobalt nitrate hexahydrate and 0.0446 g of zinc nitrate hexahydrate were dissolved in 25 ml of methanol solution, stirred for 15 minutes, and recorded as solution A. Dissolve 0.328 g of dimethylimidazole in 25 ml of methanol solution, stir for 15 minutes, and record it as solution B. Quickly inject solution B into solution A, stir for 15 minutes, and record it as solution C. Pour solution C into a 100 ml reaction kettle and react at 120°C for 1.5 hours. The obtained product was centrifuged and washed several times with methanol solution, and then the product was put into a vacuum drying oven at 70° C. to dry overnight to obtain a ZIF-67 / ZIF-8 nano-flower yellow product. The above ZIF-67ZIF-8 nanoflower powder was placed in a tube furnace, and heat-treated in an air atmosphere at 400°C for 2 hours, with a heating rate of 2°C per minute, and finally a black powder of tricobalt tetroxide / zinc oxide nanoflower composite was obtained. When zinc nitra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com