Electrolyte, preparation method thereof and lithium ion battery

An electrolyte and lithium salt technology, applied in the field of electrolyte and its preparation method and lithium ion battery, can solve the problems of reducing the discharge capacity retention rate of lithium ion battery, deteriorating the cycle stability of lithium ion battery, etc., so as to be convenient for large-scale application , High temperature cycle stability performance and discharge capacity retention rate improvement, the effect of excellent high temperature cycle stability performance and discharge capacity retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a preparation method for any one of the lithium-ion batteries described above, comprising: mixing a solvent, a lithium salt, and an additive under an inert atmosphere to obtain an electrolyte.

[0044] The solvent in the preparation method is composed of a cyclic carbonate solvent and a chain carbonate solvent, and the mass ratio of the cyclic carbonate solvent in the electrolyte is 1.5-20%, and the chain carbonate solvent is The mass proportion in the electrolyte is 47-86.1%;

[0045] The lithium salt in the preparation method is lithium hexafluorophosphate, and lithium bisfluorosulfonyl imide and / or lithium bistrifluoromethanesulfonyl imide;

[0046] The additive in the preparation method is selected from one or more of vinyl sulfite, lithium difluorobisoxalate borate, lithium difluorobisoxalate phosphate, vinylene carbonate and thiophene.

[0047] Specifically, it can be carried out in a glove box (moisture <10 ppm, oxygen <1 ppm)...

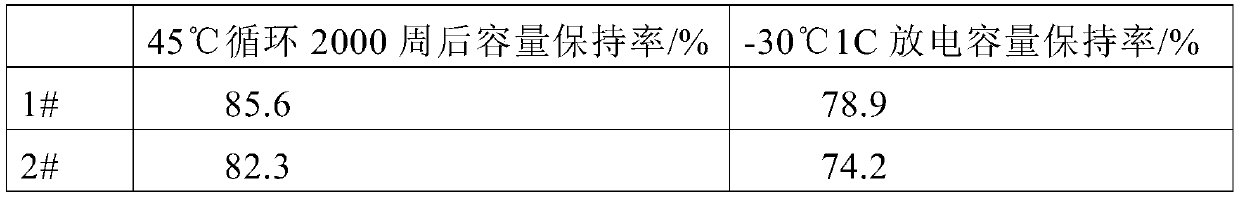

Embodiment 1

[0069] The electrolyte solution of this embodiment includes the following components according to mass percentage: ethylene carbonate 3%, dimethyl carbonate 66%, methyl ethyl carbonate 16%, vinyl sulfite 0.5%, difluorobisoxalate lithium borate 0.5% %, lithium hexafluorophosphate 4%, lithium bisfluorosulfonimide 10%.

[0070] Ethylene carbonate, dimethyl carbonate, ethyl methyl carbonate, vinyl sulfite, lithium difluorobisoxalate borate, lithium hexafluorophosphate, and lithium bisfluorosulfonimide were mixed according to the above proportions to obtain the electrolyte solution of this embodiment.

[0071] The electrolyte in this embodiment is matched with LiNi 0.8 co 0.1 mn 0.1 o 2 The positive electrode, PP diaphragm and graphite negative electrode are assembled into Li-ion battery 1#.

Embodiment 2

[0073] The electrolyte solution of this embodiment includes the following components according to mass percentage: 8.5% ethylene carbonate, 70% dimethyl carbonate, 4% ethyl methyl carbonate, 1.5% vinylene carbonate, 8% lithium hexafluorophosphate, difluorosulfonic acid Lithium imide 8%.

[0074] Ethylene carbonate, dimethyl carbonate, ethyl methyl carbonate, vinylene carbonate, lithium hexafluorophosphate, and lithium bisfluorosulfonimide were mixed according to the above proportions to obtain the electrolyte solution of this embodiment.

[0075] The electrolyte in this embodiment is matched with LiNi 0.8 co 0.1 mn 0.1 o 2 The positive electrode, PP diaphragm and graphite negative electrode are assembled into Li-ion battery 2#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com