Manufacturing method for non-woven fabric wet tissues

A manufacturing method and non-woven technology, applied in the field of daily chemical products, can solve the problems of environmental pollution, preservatives and fungicides, inability to recycle in bags, short shelf life of bacteria, etc. Improve shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

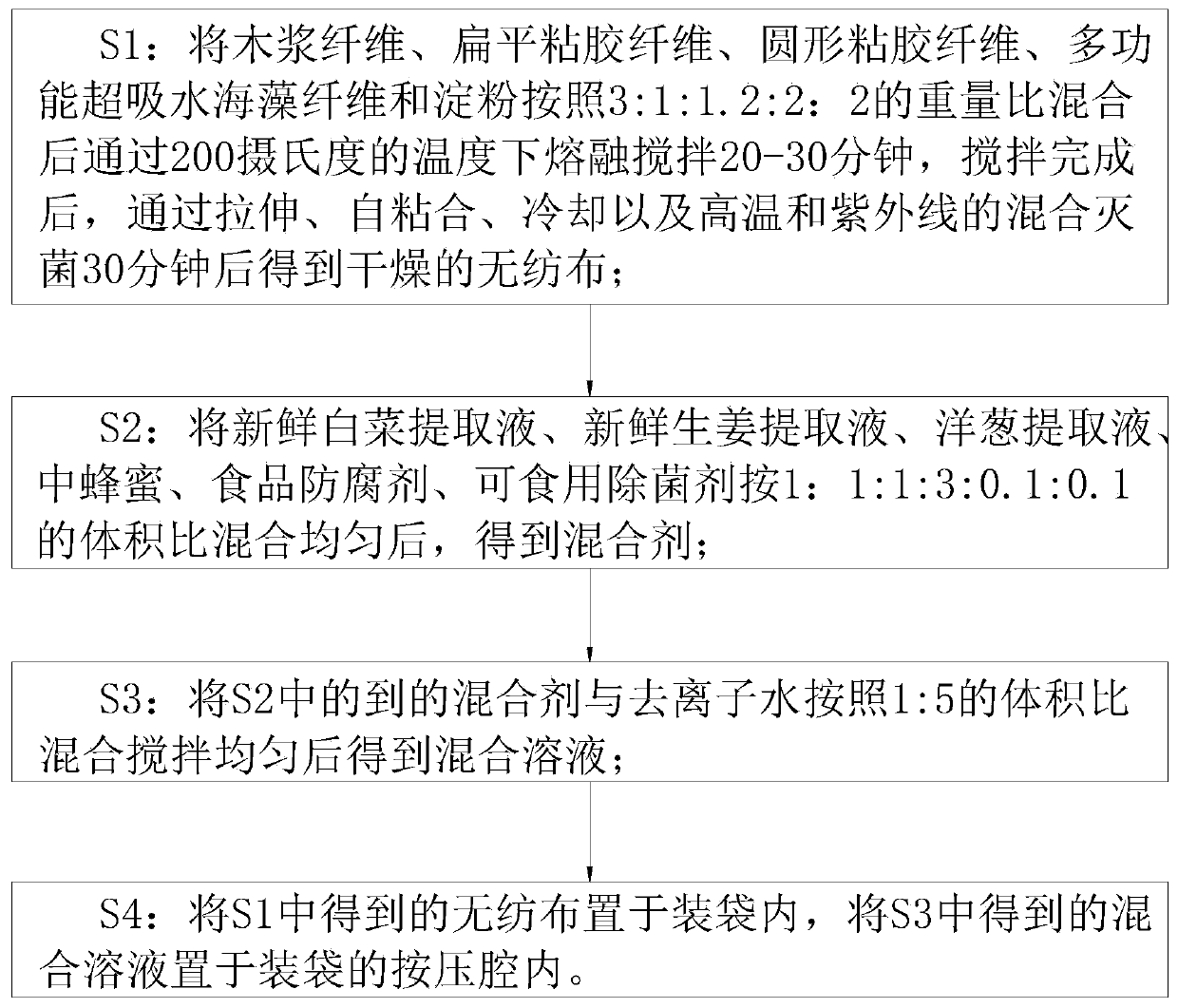

Method used

Image

Examples

Embodiment approach

[0032] As an embodiment of the present invention, the mixed solution also includes turmeric extract, Jiulixiang extract, triangular-edge extract and zedoary extract, and its volume ratio is 1.1:1.2:1.1:1, wherein turmeric extract The volume ratio of turmeric extract to fresh cabbage extract is 1:1.2. Turmeric extract, Jiulixiang extract, Sanleng extract and Zezhu extract are Chinese herbal medicines, which have strong bactericidal and pain-relieving ability, and the mixed solution can be used on wounds. , so as to improve the scope and practicability of the wet wipes, and at the same time, the extracts of turmeric, mulberry, triangular and zedoary can be applied externally and taken internally.

[0033] As an embodiment of the present invention, the fresh Chinese cabbage extract, the fresh ginger extract and the Yangchong extract are all subjected to high-temperature deodorization treatment.

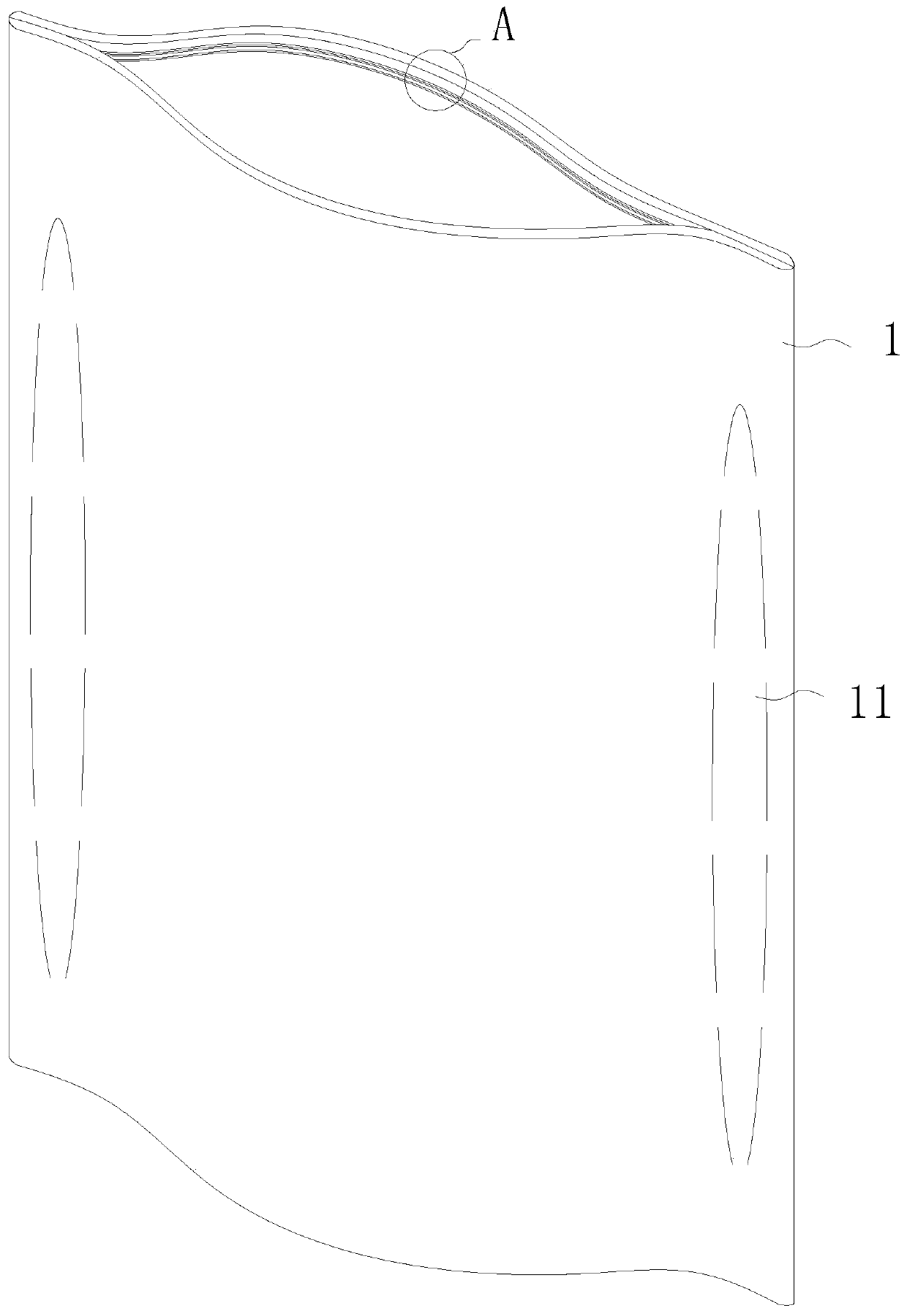

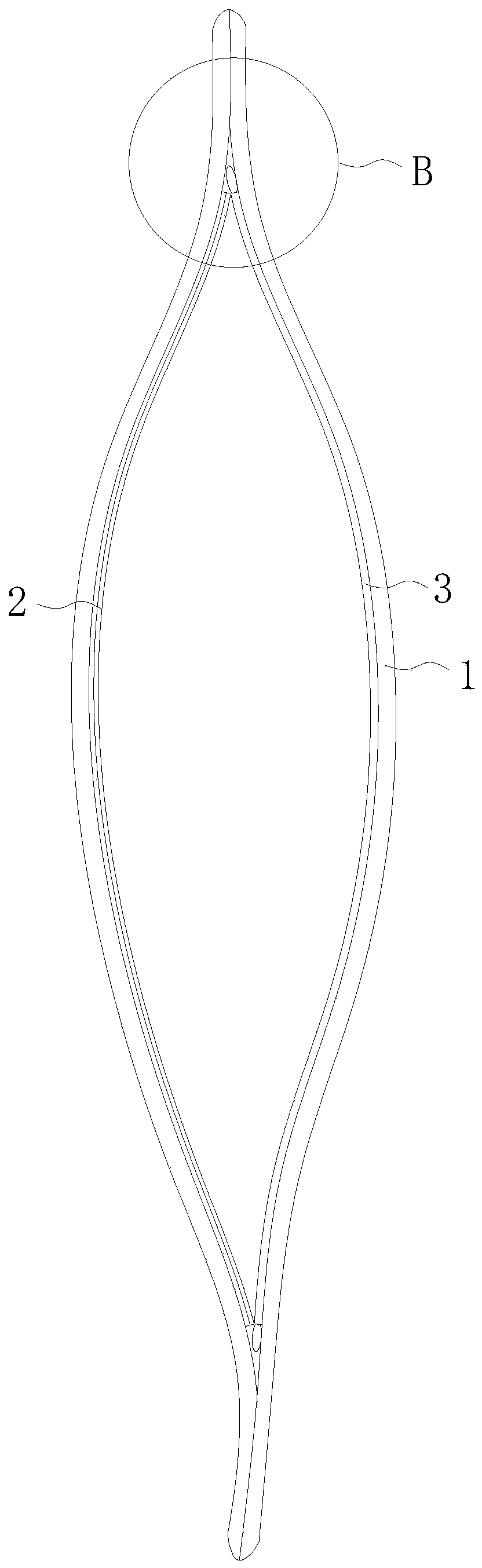

[0034] As an embodiment of the present invention, the bagging used in S4 includes a ...

Embodiment 1

[0039] Put wood pulp fiber, flat viscose fiber, round viscose fiber, multifunctional superabsorbent seaweed fiber and starch into non-woven fabric according to this method, fresh cabbage extract, fresh ginger extract, onion extract, medium honey , food preservative, edible fungicide, turmeric extract, mulberry extract, triangular extract and zedoary extract, obtain mixed solutions according to this method, and use the bagging used by this method for sale.

Embodiment 2

[0041] Put wood pulp fiber, flat viscose fiber, round viscose fiber, multifunctional superabsorbent seaweed fiber and starch into non-woven fabric according to this method, fresh cabbage extract, fresh ginger extract, onion extract, medium honey , food preservatives, edible fungicides, turmeric extracts, Jiulixiang extracts, triangular extracts and Curcuma extracts, a mixed solution is obtained according to this method, and traditional methods are used to manufacture wet wipes for sale.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com