Preparation method of water-soluble nanometer elemental selenium for livestock and poultry

A nano-element, water-soluble technology, applied in applications, animal husbandry, elemental selenium/tellurium, etc., can solve the problems of low absorption and utilization rate of animals and plants, and achieve the effects of rich production methods, easy reproduction and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

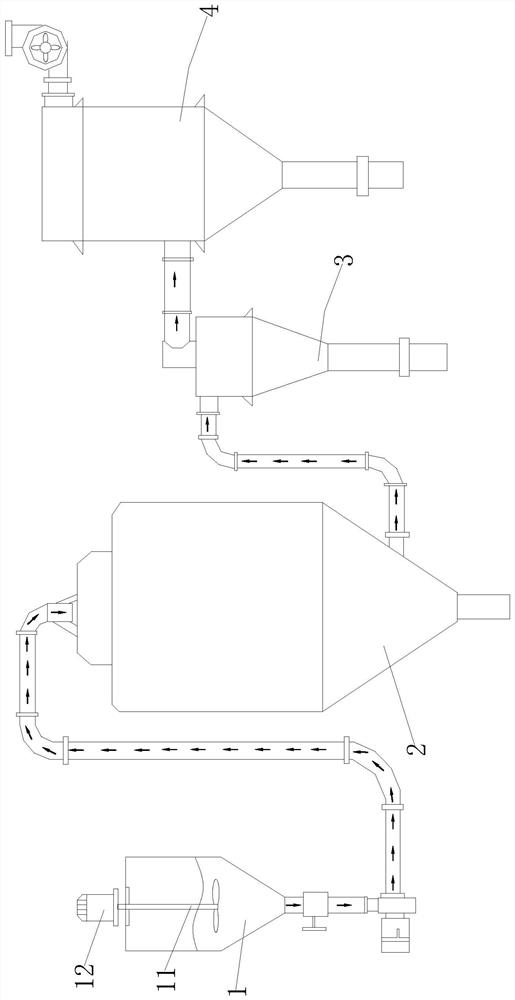

Method used

Image

Examples

Embodiment 1

[0041] Produce 50kg nano elemental selenium, comprise the following steps:

[0042] 1) Take by weighing 1.2kg of selenite, 2.5kg of reducing agent, 0.43kg of dispersant, 46kg of carrier and 70kg of water, set aside;

[0043] 2) Add water to sodium nitrite, stir until dissolved at room temperature;

[0044] 3) Add a dispersant to the solution in step 2), turn on the homogenizer, adjust the pressure to 60MPa, stir homogeneously until dissolved, and form a clear, transparent, colorless solution;

[0045] 4) Continue to add the reducing agent to the solution in step 3), the color of the solution after adding the reducing agent gradually turns red for 25 minutes, and stir until the reducing agent is completely dissolved and the reaction is basically completed;

[0046] 5) Add the carrier to the solution in 4), stir and dissolve fully;

[0047] 6) Put the solution in 5) into the centrifugal spray system through a peristaltic pump, adjust the inlet air temperature to 180°C, the out...

Embodiment 2

[0050] Produce 50kg nano elemental selenium, comprise the following steps:

[0051] 1) Take by weighing 1.2kg of sodium selenite, 2.5kg of reducing agent ascorbic acid, 300.43kg of dispersant polyvinylpyrrolidone K, 46kg of carrier modified starch, and 50kg of water, for subsequent use;

[0052] 2) Add water to sodium selenite, stir and dissolve at room temperature;

[0053] 3) Add a dispersant to step 2), turn on the homogenizer, adjust the pressure to 60MPa, stir until it dissolves, and form a clear, transparent, colorless solution.

[0054] 4) Stir continuously, the color of the solution gradually turns red after adding the reducing agent, react for 25 minutes, stir until the reducing agent is completely dissolved, and the reaction is basically completed.

[0055] 5) Add modified starch into the solution in 4), and stir to dissolve fully.

[0056] 6) Put the solution in 5) into the centrifugal spray system through a peristaltic pump, adjust the inlet air temperature to 18...

Embodiment 3

[0058] Produce 50kg nano elemental selenium, comprise the following steps:

[0059] 1) Weigh 1.2kg of sodium selenite, 2.5kg of reducing agent (ascorbic acid 1.7kg, tea polyphenol 0.8kg), dispersant 0.86kg (polysorbate 800.22kg, polyvinylpyrrolidone K300.64kg), carrier 46kg (malt Dextrin 23kg, modified starch 23kg), water 70kg, spare;

[0060] 2) Add water to sodium selenite, stir and dissolve at room temperature;

[0061] 3) Add a dispersant to step 2), turn on the homogenizer, adjust the pressure to 60MPa, stir until it dissolves, and form a clear, transparent, colorless solution.

[0062] 4) Stir continuously, the color of the solution gradually turns red after adding the reducing agent, react for 25 minutes, stir until the reducing agent is completely dissolved, and the reaction is basically completed.

[0063] 5) Add the carrier into the solution in 4), and stir to dissolve fully.

[0064] 6) Put the solution in 5) into the centrifugal spray system through a peristalti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com