Preparation method of homogeneous cross-linked-structure alkyl side chain-type polyether sulphone anion exchange membrane

An anion exchange membrane and polyaryl ether sulfone technology, which is applied in the field of preparation of polyaryl ether sulfone anion exchange membranes with homogeneous cross-linked structure alkyl side chains, can solve the problems of increased surface density, increased surface resistance, shortened service life, and low Permeability and other issues to achieve the effect of improving chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

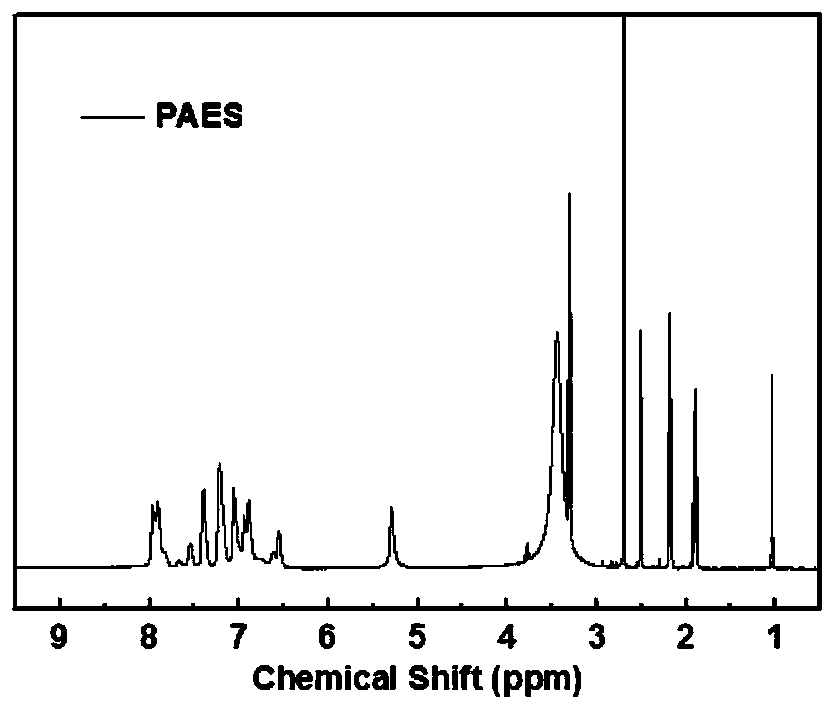

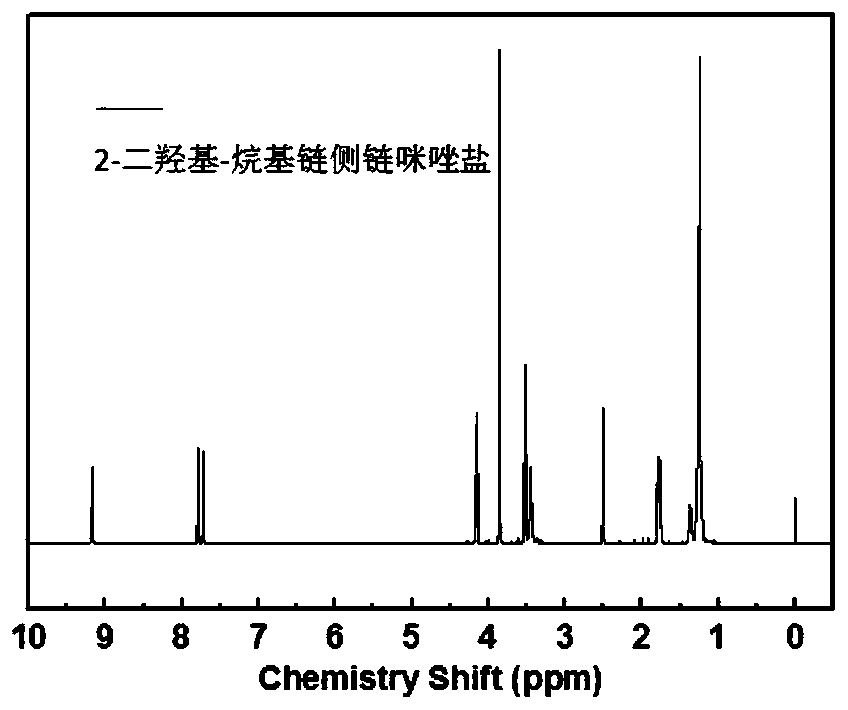

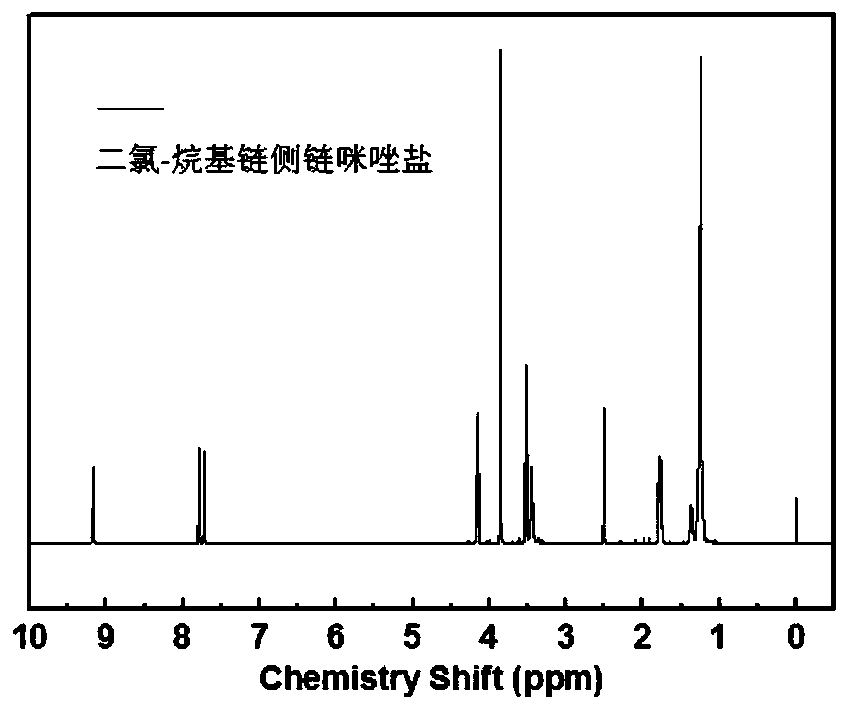

[0046] 1) Synthesis of amino-containing polyarylethersulfone: 4,4'-difluorodiphenylsulfone (20mmol, 5.0890g), 2,2'-di(4-hydroxyphenyl)hexafluoropropane (15mmol, 2.6898g ) and 2,2'-bis(3-amino-4-hydroxyphenyl)hexafluoropropane (5mmol, 4.3951g) were added into a 250mL three-necked round bottom flask equipped with a water separator, and NMP (75mL) was used as solvent, while adding 5.5gK 2 CO 3 and 40mL toluene as catalyst and water carrier respectively. in N 2 Under the atmosphere, the reaction was carried out at 155° C. for 4 hours, and further at 165° C. for 3 hours. After the polymer solution dropped to room temperature, it was poured into 300 mL of isopropanol, stirred at high speed, and flocculated to obtain a precipitate. After separation by suction filtration, a brown solid was obtained, which was repeatedly washed with isopropanol and water, and dried under vacuum at 80° C. for 20 hours. 7.3 g of 2,2'-bis(3-amino-4-hydroxyphenyl)hexafluoropropane molar fraction of 25...

Embodiment 2

[0055] 1) Synthesis of amino-containing polyarylethersulfone: 4,4'-difluorodiphenylsulfone (20mmol, 5.0890g), 2,2'-di(4-hydroxyphenyl)hexafluoropropane (13mmol, 4.3710g ) and 2,2'-bis(3-amino-4-hydroxyphenyl)hexafluoropropane (7mmol, 2.9292g) were added into a 250mL three-necked round-bottomed flask equipped with a water separator, and NMP (75mL) was used as solvent, while adding 5.5gK 2 CO 3 and 40mL toluene as catalyst and water carrier respectively. in N 2 Under the atmosphere, the reaction was carried out at 155° C. for 4 hours, and further at 165° C. for 3 hours. After the polymer solution dropped to room temperature, it was poured into 300 mL of isopropanol, stirred at high speed, and flocculated to obtain a precipitate. After separation by suction filtration, a brown solid was obtained, which was repeatedly washed with isopropanol and water, and dried under vacuum at 80° C. for 20 hours. The amino group-containing polyaryl ether sulfone with a molar ratio of 35% of...

Embodiment 3

[0060] 1) Synthesis of amino-containing polyarylethersulfone: 4,4'-difluorodiphenylsulfone (20mmol, 5.0890g), 2,2'-bis(4-hydroxyphenyl)hexafluoropropane (11mmol, 3.6985g ) and 2,2'-bis(3-amino-4-hydroxyphenyl)hexafluoropropane (9mmol, 3.7661g) were added into a 250mL three-necked round-bottomed flask equipped with a water separator, and NMP (75mL) was used as solvent, while adding 5.5gK 2 CO 3 and 40mL toluene as catalyst and water carrier respectively. in N 2 Under the atmosphere, the reaction was carried out at 155° C. for 4 hours, and further at 165° C. for 3 hours. After the polymer solution dropped to room temperature, it was poured into 300 mL of isopropanol, stirred at high speed, and flocculated to obtain a precipitate. After separation by suction filtration, a brown solid was obtained, which was repeatedly washed with isopropanol and water, and dried under vacuum at 80° C. for 20 hours. The amino group-containing polyaryl ether sulfone with a molar ratio of 45% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com