A method to reduce the risk of emulsification of heavy oil during steam stimulation

A heavy oil and steam technology, which is applied in the direction of earthwork drilling, wellbore/well components, production fluids, etc., can solve the problems that the formation emulsification cannot be effectively solved, accelerate the emulsification of heavy oil, and frequently operate the process, so as to reduce the emulsification of heavy oil Risk, operability, and effect of improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0064] Implementation case 1: The third round of huff and puff drainage of well A23H in Lvda 27-2 oilfield in Bohai Sea was not timely resulting in emulsification and poor huff and puff effect.

[0065] Figure 12 It is the location of two steam huff and puff wells in Luda 27-2 oilfield.

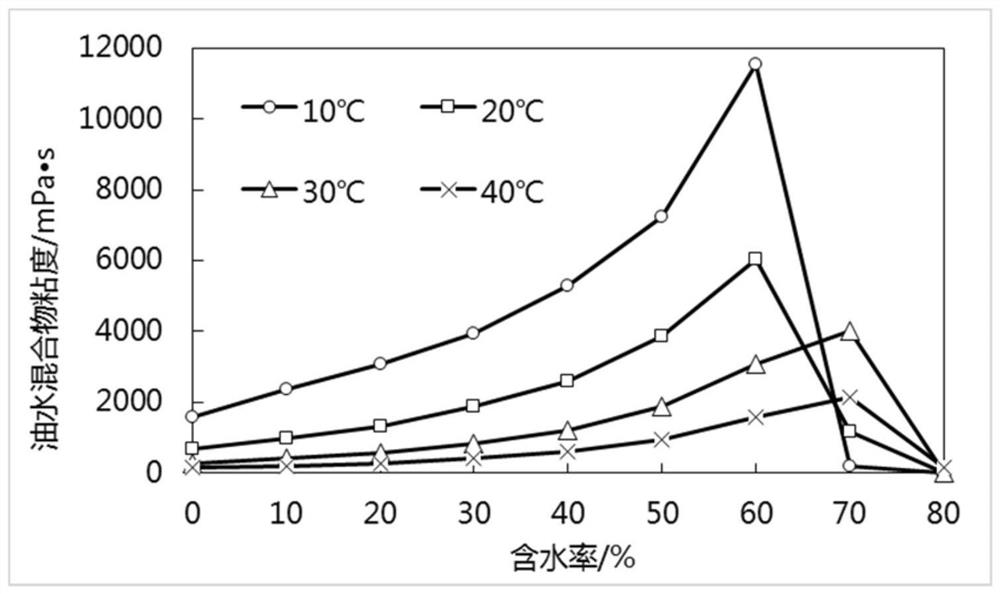

[0066] Figure 13(a) shows the daily oil production and water cut curve of Well A23H in Lvda 27-2 Oilfield, which is divided into three stages: the natural energy depletion exploitation stage, the main goal is to determine the production capacity of cold recovery; the first round of steam huff and puff, injection Steam 4500m 3 , the bottom hole injection temperature is 340℃; the second round of steam huff and puff, injecting steam 5250m 3 , Bottom hole injection temperature is 340°C. The viscosity of degassed and dehydrated crude oil in Well A23H at 50°C was 2462mPa·s. After the second round of huff and puff well was opened, the production capacity dropped rapidly. After sampling, the visc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com