Online control method for concentration of emulsion of two-time cold rolling unit

A technology of secondary cold rolling and control method, which is applied in the direction of rolling mill control device, metal rolling, metal rolling, etc., can solve the problem of narrow adjustable range, reduce strip thickness fluctuation, improve rolling stability and The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

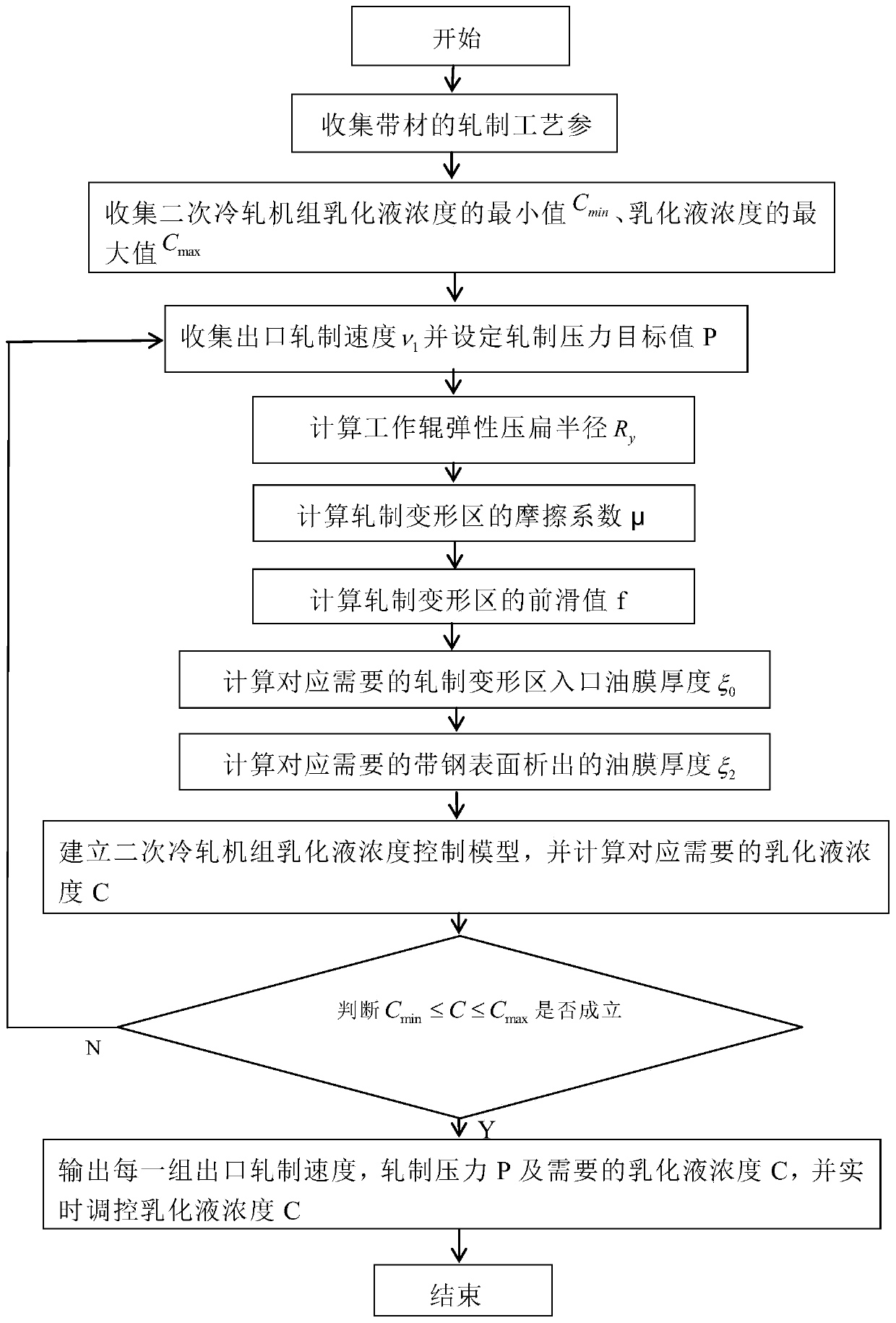

Method used

Image

Examples

Embodiment 1

[0067] S1. Collect strip specifications, steel types, front and rear tension, reduction rate, emulsion flow and rolling process parameters; that is, reduction Δh=0.050mm, rolling bite angle α=0.012, strip deformation resistance K= 390MPa, rolling oil dynamic viscosity η 0 =0.023 / Pa·s, pressure viscosity coefficient θ=0.012MPa -1 , strip width B = 0.847m, entrance thickness h 0 =0.200mm, outlet thickness h 1 =0.150mm, post tension stress σ 0 =117MPa, pre-tension stress σ 1 =169MPa, emulsion flow rate Q=9.4L·min -1 , Emulsion separation distance L=0.5m, work roll radius R=162mm, work roll elastic modulus E=210000MPa, work roll Poisson’s ratio ν=0.3, emulsion concentration precipitation efficiency time influence coefficient λ t =487.6, Emulsion concentration and precipitation efficiency Concentration influence system λ w =193.5, emulsion flow, remaining efficiency time influence coefficient δ t =19.25, Emulsion flow residual efficiency flow influence coefficient δ Q =0.49...

Embodiment 2

[0088] S1. Collect the specifications of the strip, steel type, front and rear tension, reduction rate, emulsion flow and rolling process parameters; that is, the reduction Δh=0.040mm, the rolling bite angle α=0.012, and the strip deformation resistance K= 400MPa, rolling oil dynamic viscosity η 0 =0.02 / Pa·s, pressure viscosity coefficient θ=0.01MPa -1 , strip width B = 0.847m, entrance thickness h 0 =0.192mm, outlet thickness h 1 =0.152mm, post tension stress σ 0 =115MPa, pre-tension stress σ 1 =157MPa, emulsion flow rate Q=9.6Lmin -1 , Emulsion separation distance L=0.5m, work roll radius R=170mm, work roll elastic modulus E=210000MPa, work roll Poisson’s ratio ν=0.3, emulsion concentration precipitation efficiency time influence coefficient λ t =478.6、Emulsion concentration and precipitation efficiency Concentration influence system λ w =188.5, Emulsion flow residual efficiency time influence coefficient δ t =21.26, emulsion flow residual efficiency flow influence co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com