Preparation method of nitrogen-sulfur co-doped porous graphene by means of supramolecular template method

A technology of nitrogen-sulfur co-doping and porous graphene, applied in the direction of graphene, nano-carbon, etc., can solve the problems of large force of graphene sheets, loss of active sites, unfavorable electrolyte penetration, etc., and achieve easy scale The effect of synthesis, low cost, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Prepare 150 mL of graphene oxide aqueous solution with a concentration of 2 mg / mL, ultrasonically disperse for 30 min, and add 100 mL of nitrogen-nitrogen dimethylformamide.

[0026] Step 2: Add 420 mg of melamine and 570 mg of thiocyanuric acid to the graphene oxide dispersion liquid in sequence under stirring at 80° C., and react for 5 hours.

[0027] Step 3: hot filter the reaction product, wash it several times, and dry it in a constant temperature oven at 90° C. for 12 hours to obtain a composite of graphene oxide and melamine thiocyanate.

[0028] Step 4: Put the composite in a tube furnace, and heat it to 800° C. at a heating rate of 5° C. / min under an argon atmosphere, and continue heating for 2 hours to prepare nitrogen-sulfur co-doped porous graphene.

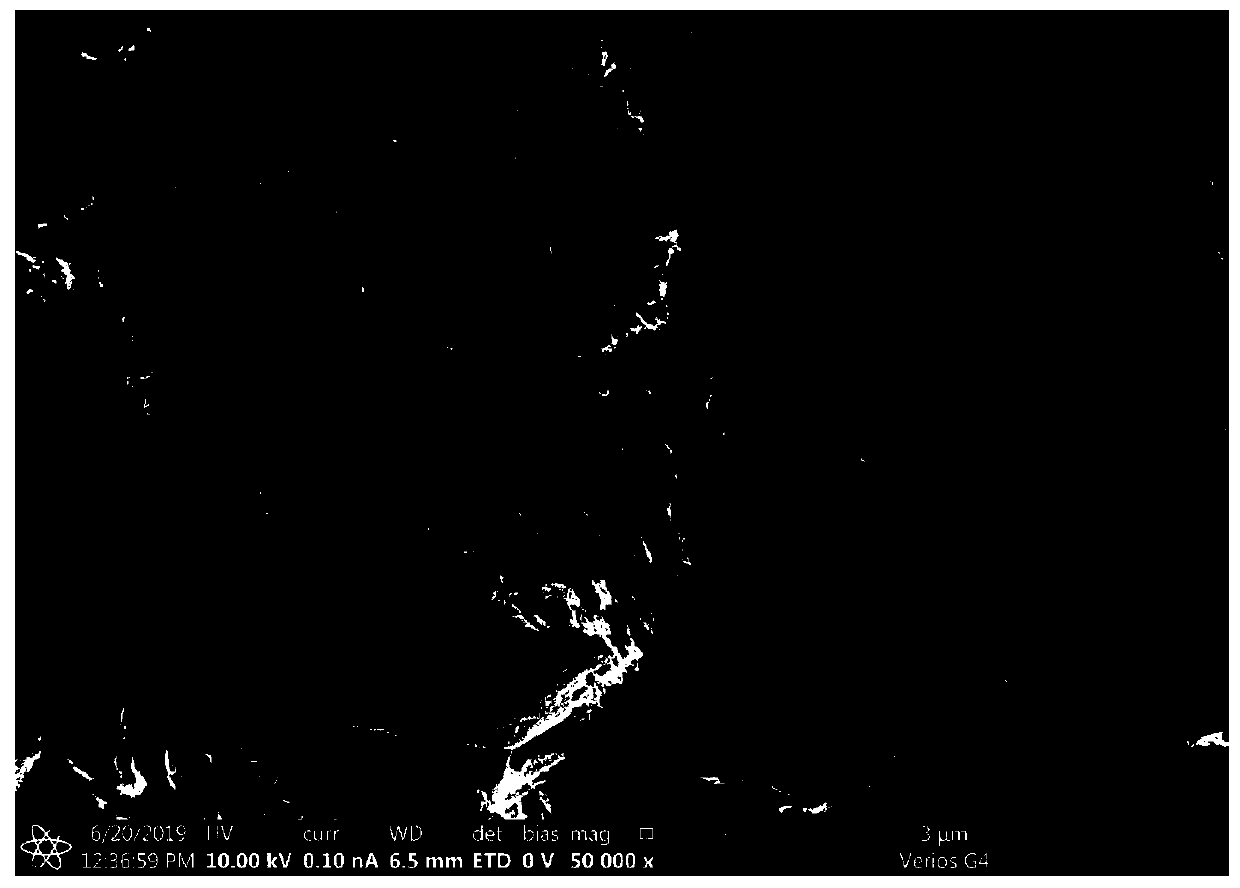

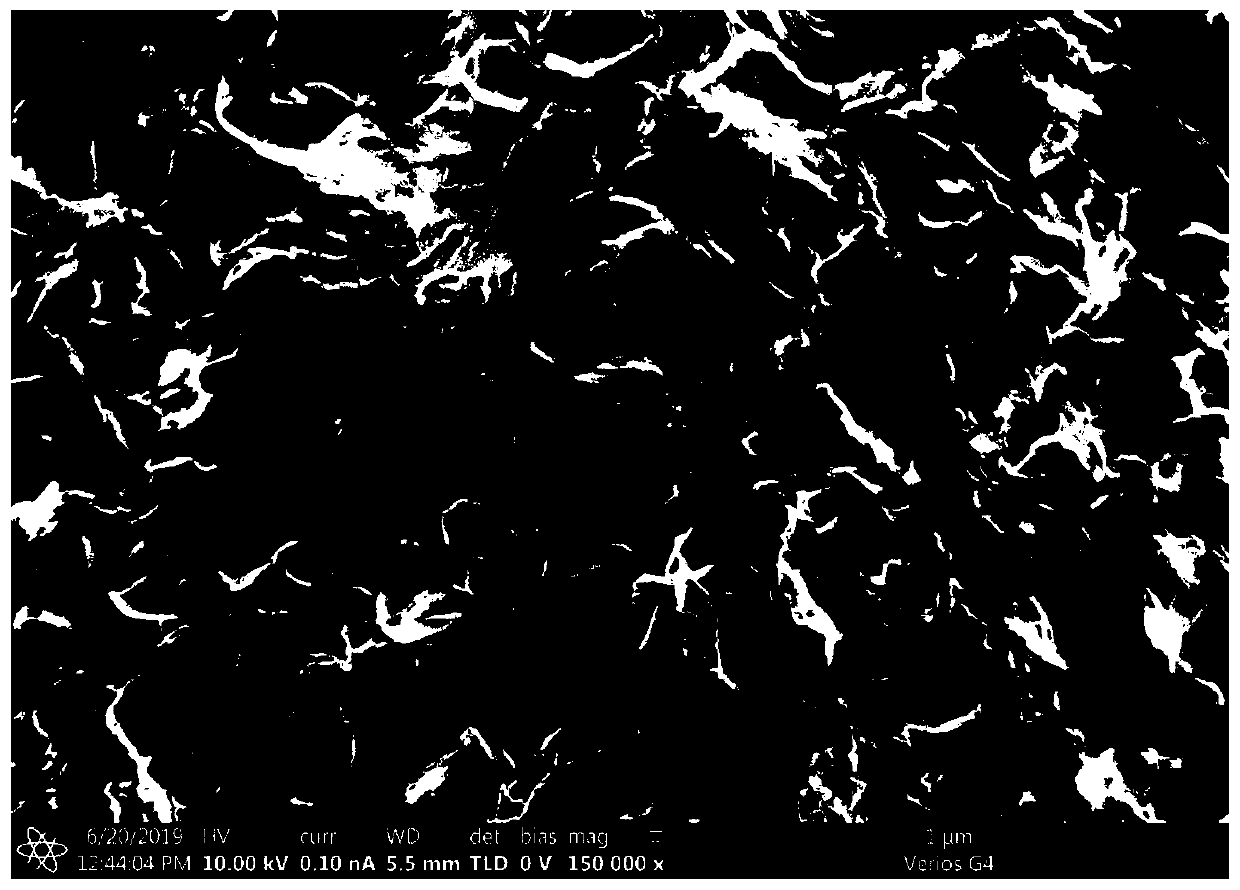

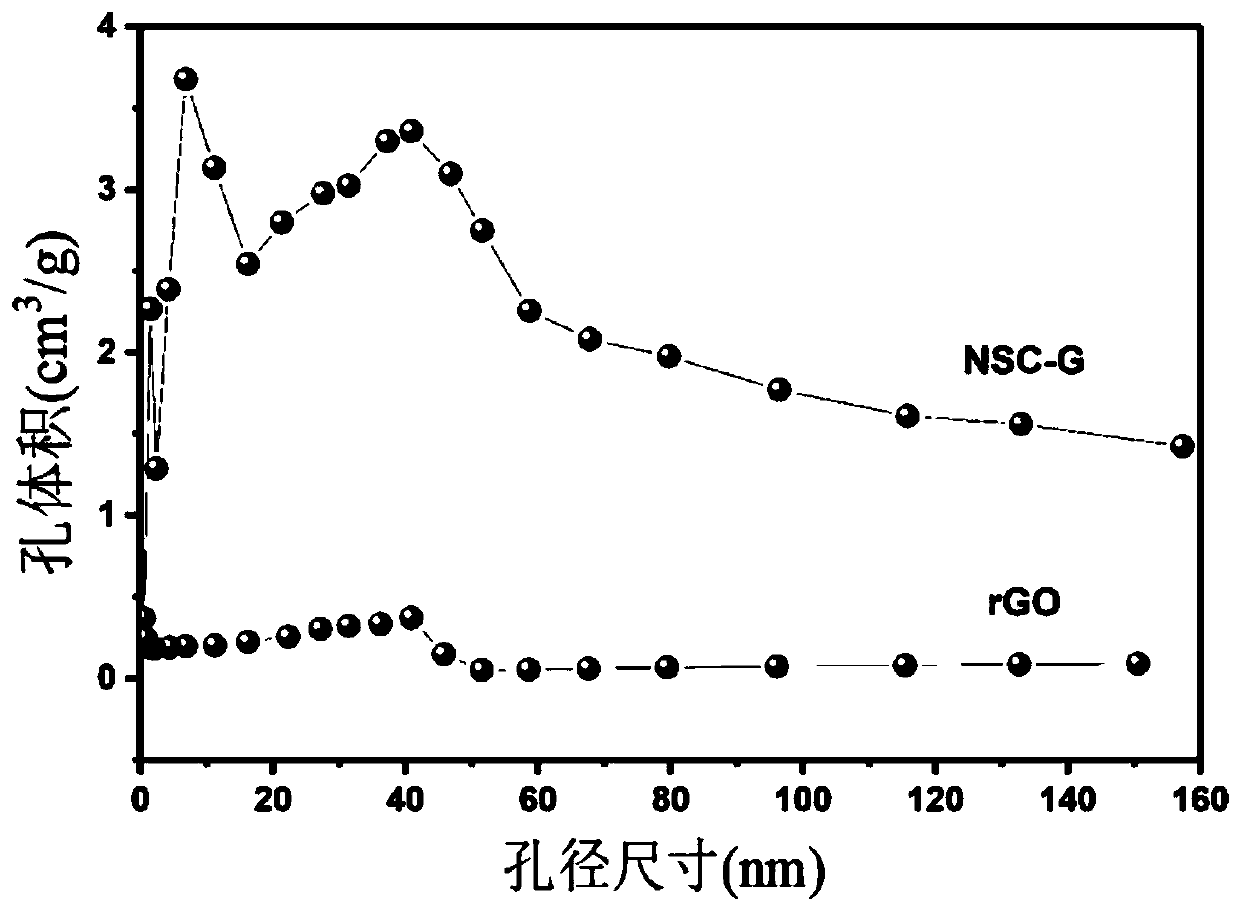

[0029] figure 1 It is the SEM figure of the nitrogen-sulfur co-doped porous graphene prepared by the present embodiment, figure 2 yes figure 1 The magnified view of , from which it can be seen that ...

Embodiment 2

[0033] Step 1: Prepare 150 mL of graphene oxide aqueous solution with a concentration of 2 mg / mL, ultrasonically disperse for 30 min, and add 100 mL of nitrogen-nitrogen dimethylformamide.

[0034] Step 2: Add 420 mg of melamine and 570 mg of thiocyanuric acid to the graphene oxide dispersion at 60°C while stirring, and react for 10 hours.

[0035] Step 3: hot filter the reaction product, wash it several times, and dry it in a constant temperature oven at 90° C. for 12 hours to obtain a composite of graphene oxide and melamine thiocyanate.

[0036] Step 4: Put the composite in a tube furnace, heat it to 900° C. at a heating rate of 5° C. / min under an argon atmosphere, and continue heating for 2 hours to prepare nitrogen-sulfur co-doped porous graphene.

Embodiment 3

[0038] Step 1: Prepare 100 mL of graphene oxide aqueous solution with a concentration of 2 mg / mL, ultrasonically disperse for 30 min, and add 100 mL of nitrogen-nitrogen dimethylformamide.

[0039] Step 2: Add 250 mg of melamine and 350 mg of thiocyanuric acid to the graphene oxide dispersion in sequence at 80° C. with stirring, and react for 2 hours.

[0040] Step 3: hot filter the reaction product, wash it several times, and dry it in a constant temperature oven at 90° C. for 12 hours to obtain a composite of graphene oxide and melamine thiocyanate.

[0041] Step 4: Put the compound in a tube furnace, heat it to 800° C. at a heating rate of 5° C. / min under an argon atmosphere, and continue heating for 1 hour to prepare nitrogen-sulfur co-doped porous graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com