Modification method for natural graphite, modified natural graphite and application of modified natural graphite

A natural graphite and modification technology, which is applied in the modification of natural graphite, modified natural graphite and application fields, can solve the problems such as the gap in the cycle life of artificial graphite, and achieve high initial discharge capacity, simple production process, and improved reversible capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

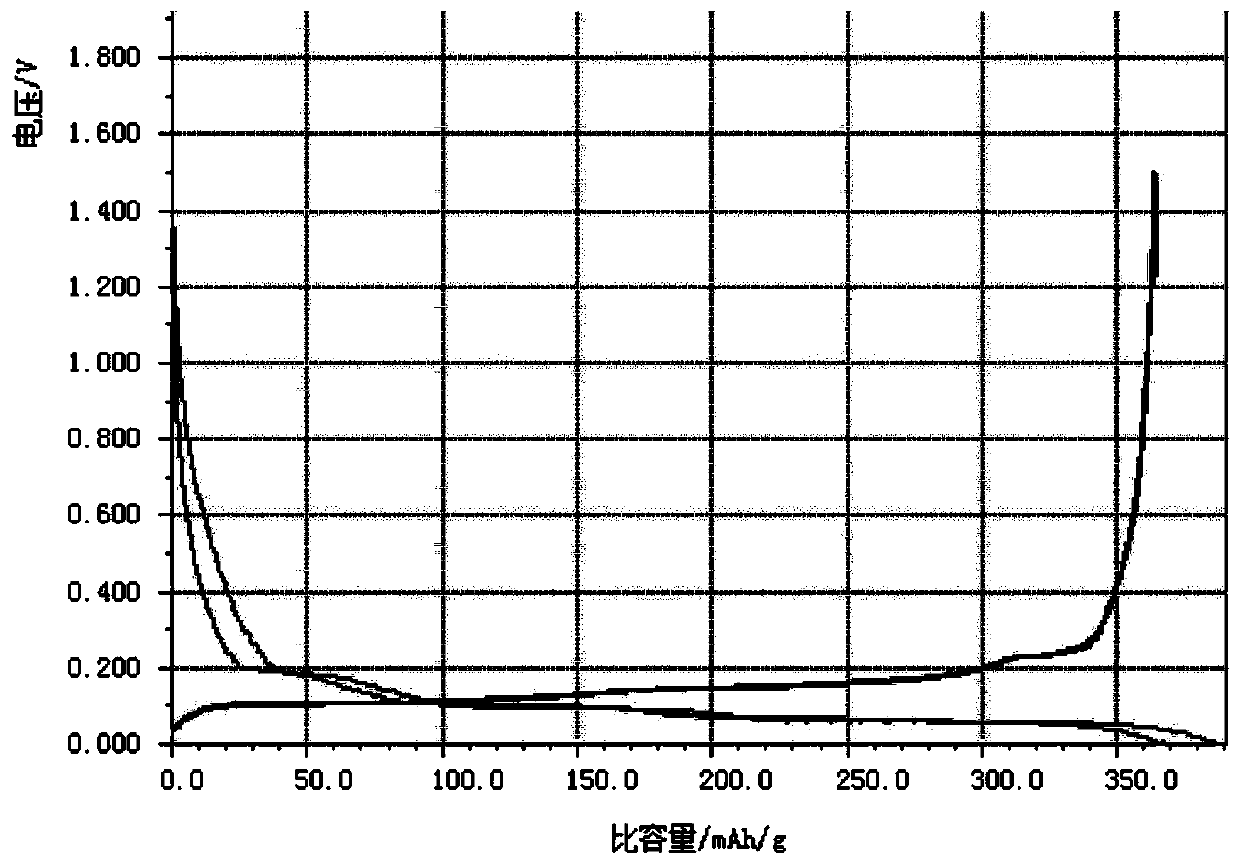

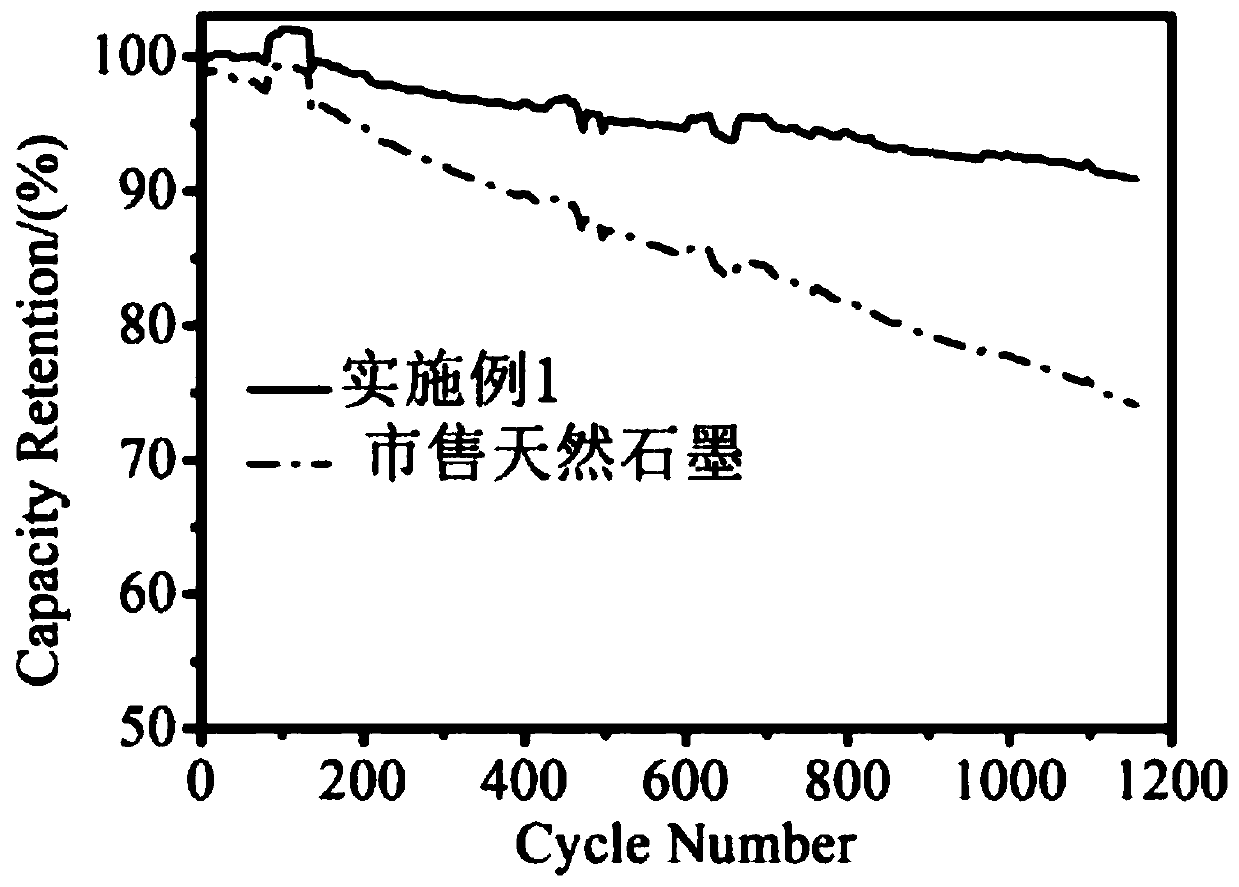

[0025] Take 1000g particle size is 5.8μm, tap density is 0.68g / m 2 , the specific surface area is 8.5m 2 / g of spheroidized natural graphite was put into a muffle furnace, treated at a constant temperature of 650°C for 3 hours in an air atmosphere, and then taken out after cooling to obtain partially oxidized natural graphite. 528g of heavy oil, 85g of asphalt and 11g of phenolic resin were stirred at room temperature for 20 minutes to obtain a liquid-phase coating agent. Then mix 820g of partially oxidized natural graphite with 180g of liquid-phase coating agent for 20min, 2 Carbonized at 1150°C for 3.5h under the protection of the carbon dioxide, then graphitized at 2500°C, and modified natural graphite was obtained after cooling.

[0026] After the above-mentioned modified natural graphite is pulverized, shaped and classified, the lithium ion battery negative electrode material is obtained.

Embodiment 2

[0028] Take 1000g, the particle size is 7.5μm, and the tap density is 0.71g / m 2 , the specific surface area is 8.2m 2 / g of spheroidized natural graphite was put into a muffle furnace, treated at a constant temperature of 600°C for 2 hours in an air atmosphere, and then taken out after cooling to obtain partially oxidized natural graphite. 678g of heavy oil, 75g of asphalt and 13g of phenolic resin were stirred at room temperature for 20 minutes to obtain a liquid-phase coating agent. Then mix 800g of partially oxidized natural graphite with 150g of liquid-phase coating agent for 20min, 2 Carbonization at 900°C for 3 hours under the protection of the carbon dioxide, and then graphitization at 2600°C, and modified natural graphite was obtained after cooling.

[0029] After the above-mentioned modified natural graphite is pulverized, shaped and classified, the lithium ion battery negative electrode material is obtained.

Embodiment 3

[0031] Take 1000g, the particle size is 8.6μm, and the tap density is 0.78g / m 2 , the specific surface area is 7.5m 2 / g of spheroidized natural graphite was put into a muffle furnace, treated at a constant temperature of 800°C for 5 hours in an air atmosphere, and taken out after cooling to obtain partially oxidized natural graphite. 615g of heavy oil, 60g of asphalt and 10g of phenolic resin were stirred at room temperature for 20 minutes to obtain a liquid-phase coating agent. Then mix 800g of partially oxidized natural graphite with 120g of liquid-phase coating agent for 20min, 2 Carbonization at 1200°C for 5 hours under the protection of the carbon dioxide, and then graphitization at 2800°C, and modified natural graphite was obtained after cooling.

[0032] After the above-mentioned modified natural graphite is pulverized, shaped and classified, the lithium ion battery negative electrode material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com