A method for synergistically treating cadmium with a controllable degradation collector in wastewater from lead-zinc sulfide mines

A technology of lead-zinc sulfide and synergistic treatment, applied in chemical instruments and methods, multi-stage water/sewage treatment, light water/sewage treatment, etc., can solve the problems of secondary pollution, high cost, and lack of popularization, and achieve pollution Less, simple process, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Indoor test 1

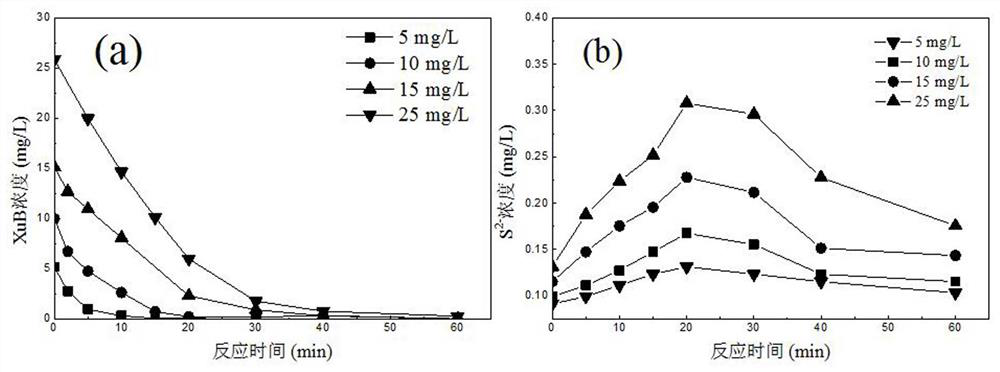

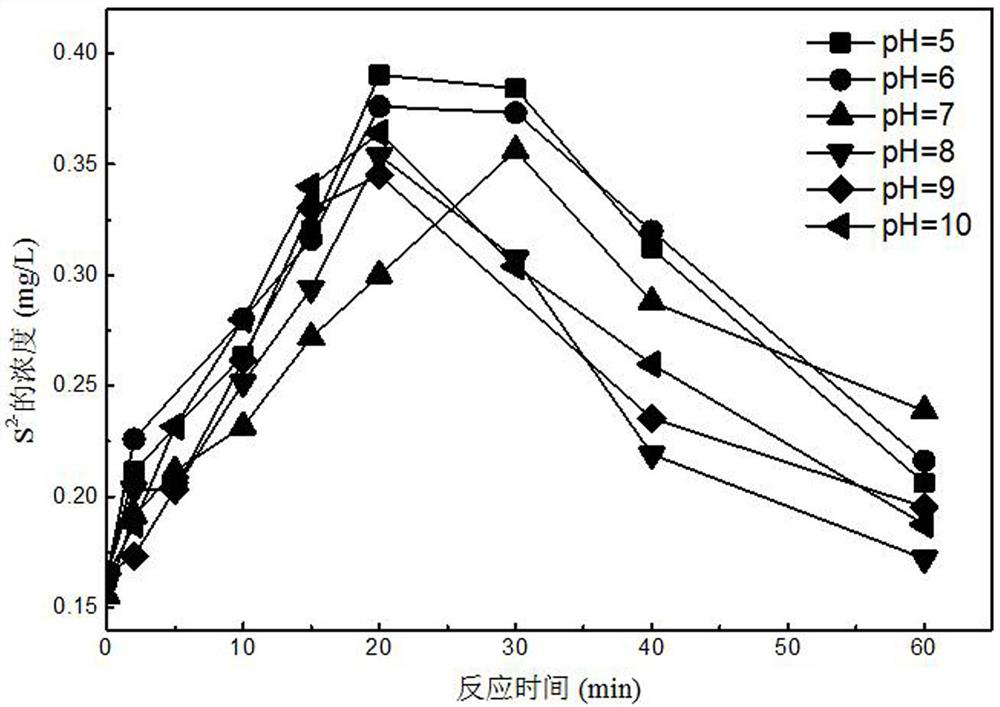

[0035] Xanthate concentration and solution pH versus S 2- Effect test of concentration maximum

[0036] Test method: Prepare a standard solution with a xanthate concentration of 100 mg / L as a stock solution. The experiments on the degradation of different concentrations of xanthate and the effect of pH on the maximum value of xanthate were carried out in a cylindrical glass reactor. Take a certain volume of the stock solution and transfer it into the reactor, add deionized water until the final reaction volume is 1.0 L, and place the reactor on a magnetic stirrer to fully stir at a speed of 400 r / min. Irradiate with a low-pressure vacuum ultraviolet lamp (185 nm+254 nm). Samples were taken at 0, 2, 5, 10, 15, 20, 30, 40, 60 min.

[0037] Degradation test of different concentrations of xanthate: adjust the concentration gradient of xanthate to 5, 10, 15, and 25 mg / L, measure the concentration of xanthate and sulfur ion according to the above sampling ...

Embodiment 2

[0048] Indoor test 2

[0049] Simulated wastewater Cd 2+ Removal of Certification Tests

[0050] Test method and steps:

[0051] 1. The xanthate with a concentration of 100 mg / L is used as a stock solution; the cadmium (Cd 2+ ) as the stock solution.

[0052] 2. Cd 2+ Removal qualification tests were performed in a cylindrical glass reactor. Take a certain volume of xanthate stock solution and transfer it to the reactor, add deionized water to a final reaction volume of 1.0 L, prepare a xanthate solution with a concentration of 10 mg / L, and place the reactor at a speed of 400 r / min. On a magnetic stirrer, irradiate with a low-pressure vacuum ultraviolet lamp (185 nm+254 nm) for 30 min.

[0053] 3. Add CdCl to the reactor 2 , so that Cd in the reactor 2+ Concentration of 1 mg / L, sample determination of xanthate concentration and Cd 2+ Concentration (recorded as the first sampling), continue to irradiate with a low-pressure vacuum ultraviolet lamp (185 nm+254 nm) for 10...

Embodiment 3

[0061] Mineral processing wastewater pilot test 1

[0062] The situation of mineral processing wastewater exceeding the standard in the test area is: COD exceeds the standard by 0.8 times, Cd 2+ 1.72 times higher than the standard.

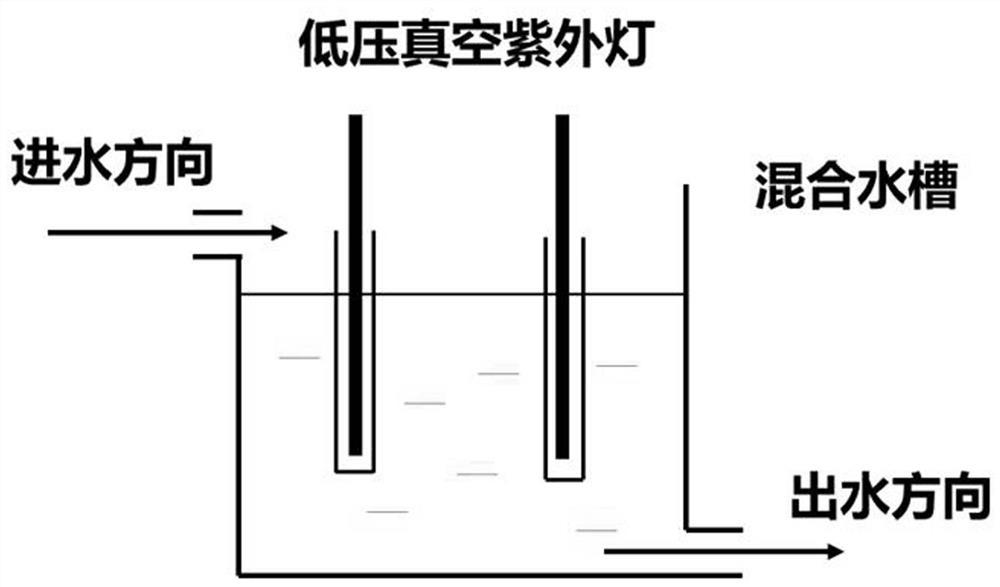

[0063] Test method and steps: 1. If figure 1 As shown, the time from the production of the flotation concentrate to the pressure filtration is controlled within 30 minutes, and the pressure filtration water of the concentrate is immediately passed into the reaction tank 1, and treated with the VUV method for 15 minutes. 2. Pass the treated concentrated ore press water and tailings press water into the reaction pool 2, use the VUV method for 10 minutes, then filter and discharge. Determination of COD and Cd before and after treatment 2+ ,See Figure 7 .

[0064] Data processing and analysis:

[0065] Determination of COD: adopt rapid determination method, refer to "Determination of National Standard Chemical Oxygen Demand (GB11914-89)".

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com