Cement-based wallboard having large hollow ratio and ultrahigh toughness as well as preparation method of cement-based wallboard

A technology with ultra-high toughness and hollowness, which is applied in the field of cement-based wallboard with large hollowness and ultra-high toughness and its preparation, which can solve the problems of short life, poor toughness, and heavy weight, and achieve light weight, high toughness, and low self-weight. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A large hollow rate ultra-high toughness cement-based wallboard, which is composed of the following parts by weight of raw materials: 500 parts of ordinary Portland cement, 500 parts of mineral admixtures, 50 parts of sulphoaluminate cement, 50 parts of ultrafine powder, 60 parts of porous material, 300 parts of quartz powder, 25 parts of polypropylene fiber, 0.13 parts of cellulose ether, 6 parts of water reducing agent, 0.15 parts of defoamer, and 300 parts of water.

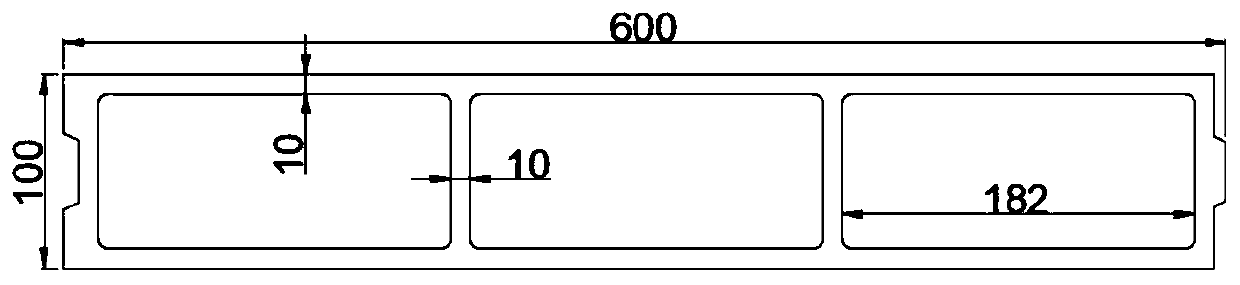

[0034] A large hollow rate ultra-high toughness cement-based wallboard section structure is as figure 1 , Its hollow rate is 73.54%.

Embodiment 2

[0036] A cement-based wallboard with large hollow rate and ultra-high toughness, composed of the following parts by weight: ordinary Portland cement 600 parts, mineral admixtures 400 parts, sulphoaluminate cement 30 parts, sodium carbonate 5 parts, borax 5 parts, 80 parts of superfine powder, 70 parts of porous material, 350 parts of quartz powder, 30 parts of polyethylene fiber, 0.1 part of cellulose ether, 5 parts of water reducing agent, 0.13 part of defoaming agent, 320 parts of water.

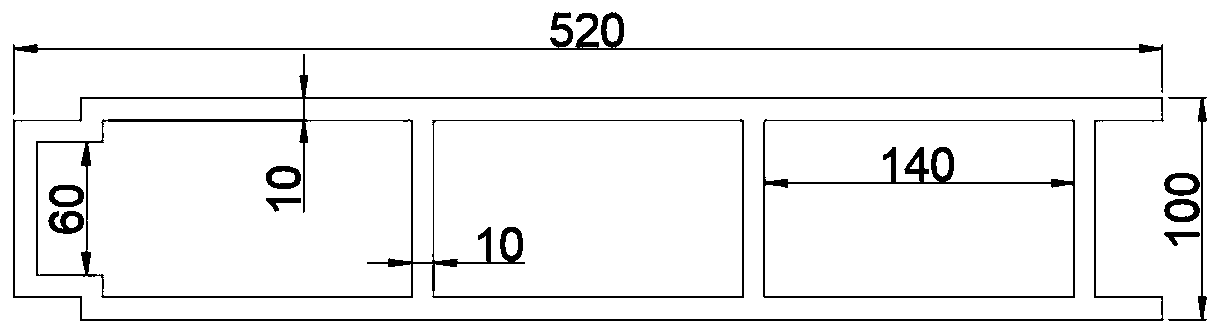

[0037] A large hollow rate ultra-high toughness cement-based wallboard section structure is as figure 2 , Its hollow rate is 73.85%.

Embodiment 3

[0039] A large hollow rate ultra-high toughness cement-based wallboard, which is composed of the following parts by weight of raw materials: 450 parts of ordinary Portland cement, 550 parts of mineral admixtures, 40 parts of sulphoaluminate cement, and 90 parts of superfine powder. 85 parts of porous material, 400 parts of quartz powder, 20 parts of polyacrylonitrile fiber, 0.2 parts of cellulose ether, 4 parts of water reducing agent, 0.13 parts of defoaming agent, 350 parts of water.

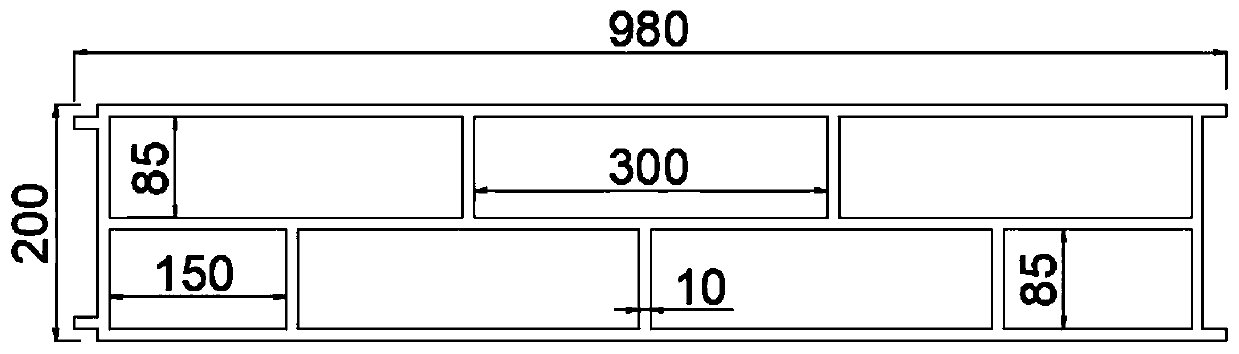

[0040] A large hollow rate ultra-high toughness cement-based wallboard section structure is as image 3 , Its hollow rate is 78.06%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com