Adhesive sheet for display and display including same

A display and bonding sheet technology, which is applied in the direction of instruments, adhesives, adhesive types, etc., can solve the problems of poor bonding force of display devices and cannot prevent static electricity, so as to achieve excellent bonding force, prevent static electricity, and reduce The effect of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0095] The above-mentioned adhesive sheet for display can be prepared by the production method described later, but it is not limited to this, and the same parts as those of the above-mentioned adhesive sheet for display will be omitted and described.

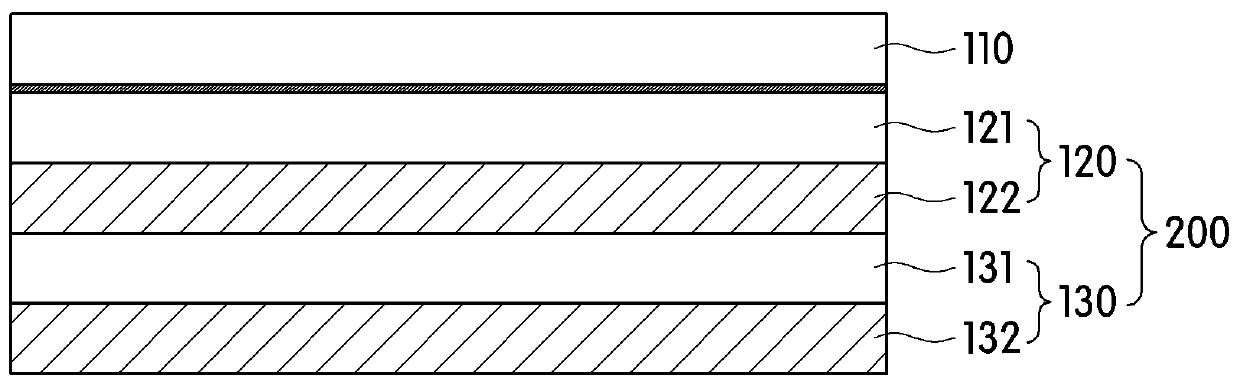

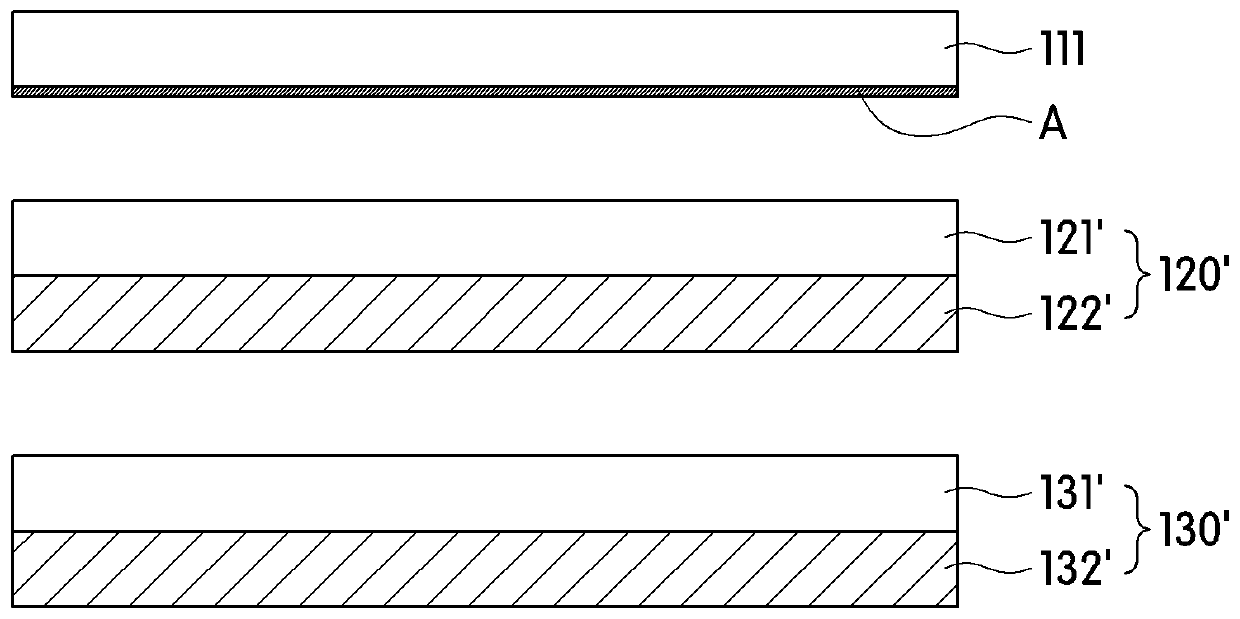

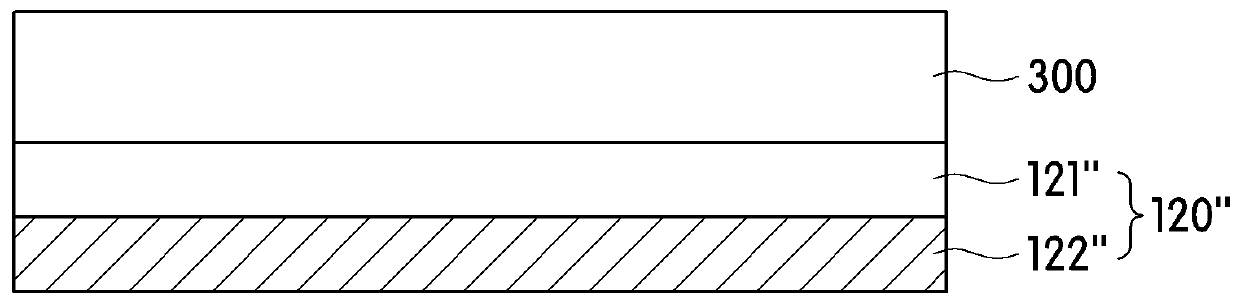

[0096] The adhesive sheet for a display of the present invention can be prepared by the following steps, including: coating a first composition containing a first main agent resin and a first antistatic agent on the upper surface of the first substrate 122 to form a first The step of bonding layer; the release film 110 is attached to the upper surface of the first substrate 122 forming the first bondable layer and the first bondable layer is cured, thereby preparing the release film 110 and the base film attached The step of 120; applying and curing the second composition on the upper surface of the second substrate to form the second adhesive layer 131 to prepare the protective film 130; and on the upper surface of the protective ...

Embodiment 1

[0119] (1) Preparation of base film and bonding release film

[0120] With respect to 100 parts by weight of the above-mentioned first main agent resin, a copolymer of an acid value of 60 mgKOH / g, a weight average molecular weight of 600,000, and random copolymerization of acrylic acid, butyl acrylate, ethyl acrylate, and vinyl acetate is used as the first The main agent resin and 0.22 parts by weight of N,N,N,N'-tetraglycidyl-m-xylylenediamine as the first curing agent, and the first antistatic agent as a solid phase at a temperature of 25°C 4.25 parts by weight of the compound represented by the following chemical formula 3 and 39 parts by weight of methyl ethyl ketone as a solvent were mixed to prepare the first composition.

[0121] In addition, poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT / PSS) was coated on the lower surface of the polyethylene terephthalate substrate with a thickness of 75 μm and applied The upper surface of the antistatic first substrate is...

Embodiment 2~15

[0130] Prepared in the same manner as in Example 1, as shown in Table 1 to Table 4 below, by changing the content of the first antistatic agent, the content of the second antistatic agent, the acid value of the first main agent resin and the second main agent resin acid Equivalent, the adhesive sheets for displays shown in Table 1 to Table 4 were prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com