Platinum-nickel-cobalt alloy@carbon nanotube composite material, preparation and application thereof

A composite material, carbon nanotube technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficulty in mass preparation, limited catalytic performance, and high cost of oxygen reduction catalyst materials, reaching Simple preparation method, improved activity and stability, and maximized performance advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of a platinum-nickel-cobalt alloy@carbon nanotube composite material provided by the present invention comprises the following steps:

[0030] (1) Mix the precursor solution containing platinum, nickel and cobalt with the metal-organic ligand solution, and a coordination reaction occurs. After the reaction is completed, the solid-liquid separation obtains a metal-organic framework containing platinum, nickel and cobalt, which is washed and dried to obtain Dried metal-organic frameworks;

[0031] (2) Annealing the metal-organic framework obtained in step (1) in a reducing atmosphere, then cleaning with dilute acid, separating and drying to obtain a platinum-nickel-cobalt alloy@carbon nanotube composite material.

[0032] Different from the traditional preparation method of alloy@carbon material, that is, the alloy material is obtained first, and then the carbon material is coated. The present invention mixes the precursor solution of platinum, nick...

Embodiment 1

[0051] Step (1): Preparation of PtNi@ZIF-67:

[0052] 3mmol (873mg) cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and 1mmol (290mg) nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) Dissolved in 20 mL of methanol (A), 12 mmol (984 mg) of 2-methylimidazole was added to another 20 mL of methanol (B), and both solutions were magnetically stirred for 0.5 hours. Chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) 10 mM solution was added to solution A, and then 2-methylimidazole solution (B) was added to the former (A). The subsequent solution was stirred at room temperature for 4 hours. The resulting purple precipitate was collected by centrifugation at 10000 rpm for 5 minutes and washed three times with methanol to remove inactive material from the product. Dry the prepared PtNi@ZIF-67 in vacuum at 70°C for 12h;

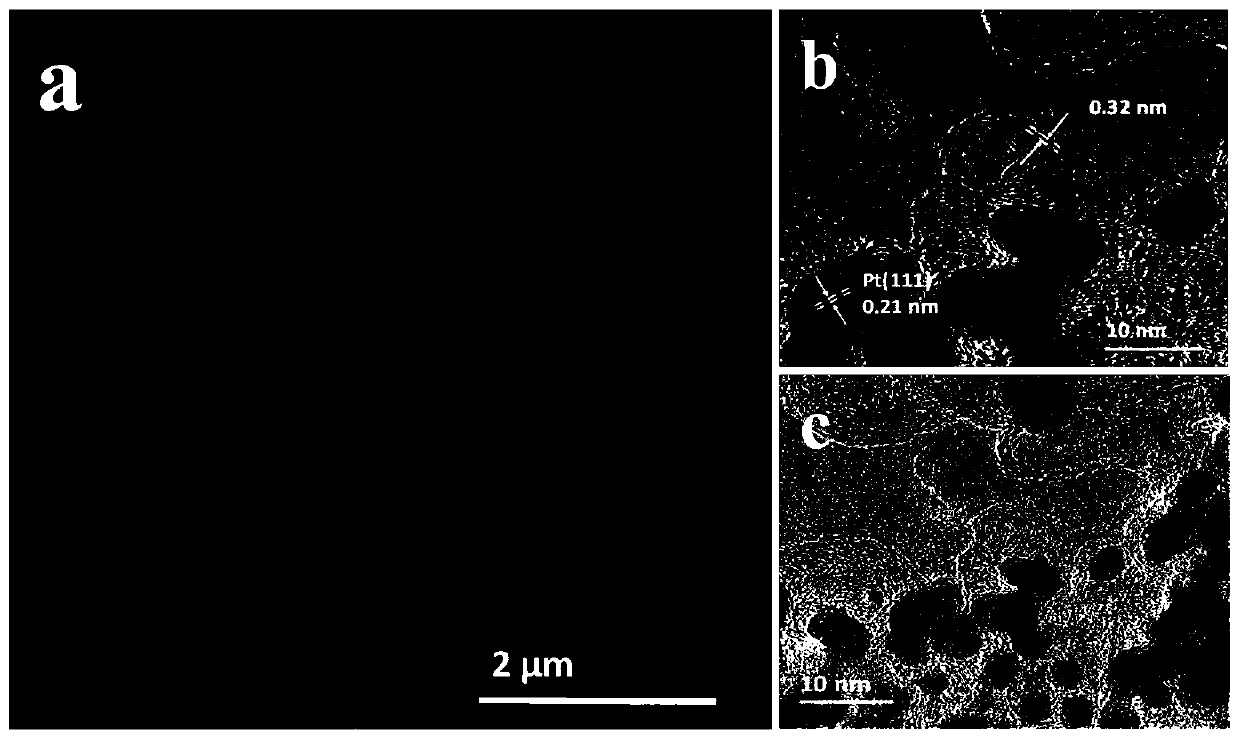

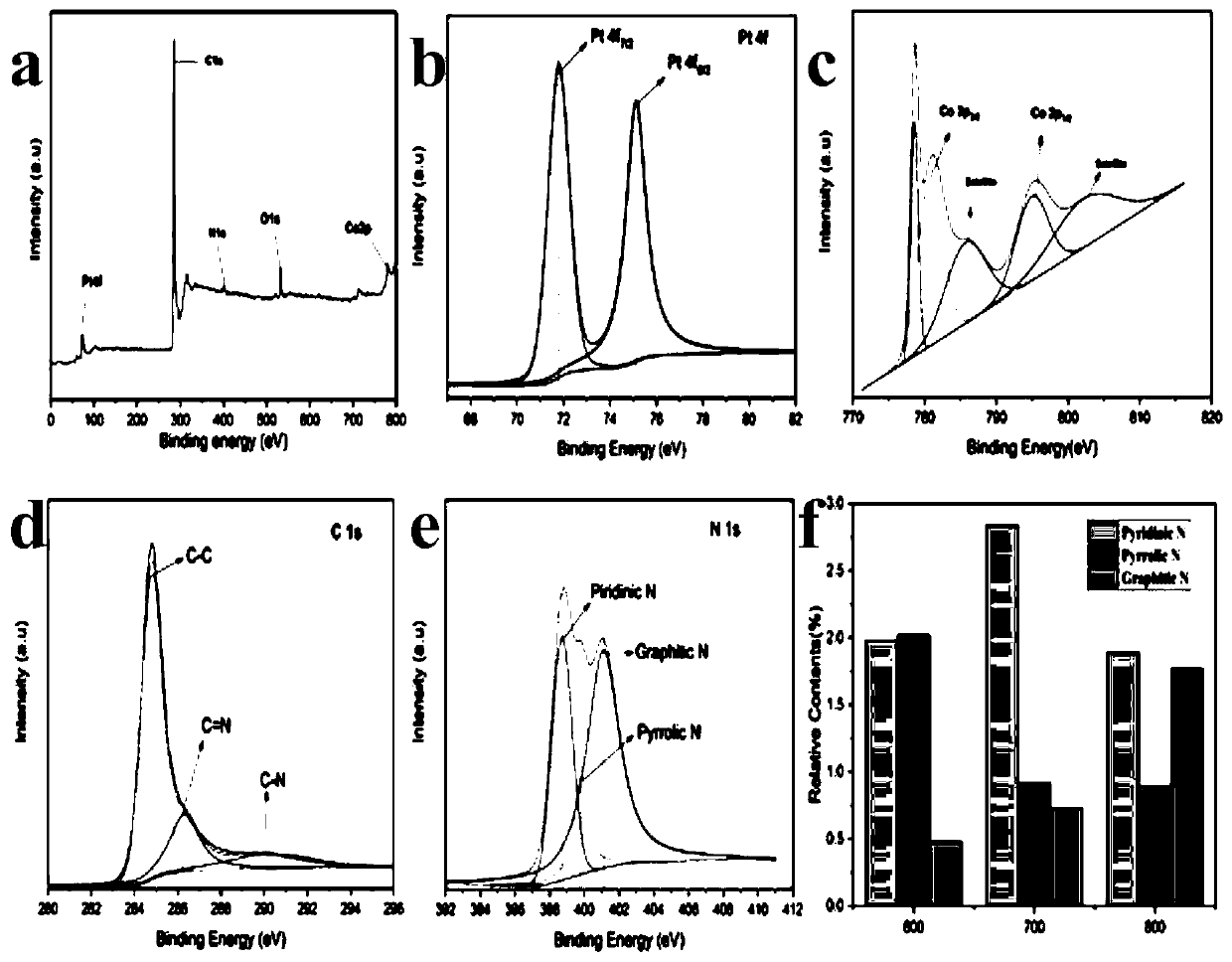

[0053] Step (2): Preparation of PtNiCo@CNTs:

[0054] 100mg of PtNi@ZIF-67 was placed in a quartz boat and transferred to a 2 mixed gas tube furnace. Heat the samp...

Embodiment 2

[0066] Step (1): Preparation of PtNi@ZIF-67:

[0067] 2mmol (582mg) cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and 1mmol (290mg) nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) Dissolved in 20 mL of methanol (A), 12 mmol (984 mg) of polyvinylpyrrolidone was added to another 20 mL of methanol (B), and both solutions were magnetically stirred for 0.5 hours. Chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) 10 mM solution was added to solution A, and then polyvinylpyrrolidone (B) was added to the former (A). The subsequent solution was stirred at room temperature for 4 hours. The resulting purple precipitate was collected by centrifugation at 10000 rpm for 5 minutes and washed three times with methanol to remove inactive material from the product. Dry the prepared PtNi@ZIF-67 in vacuum at 70°C for 12h;

[0068] Step (2): Preparation of PtNiCo@CNTs:

[0069] 100mg of PtNi@ZIF-67 was placed in a quartz boat and transferred to a 2 mixed gas tube furnace. Heat the sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com