Engraving gravure ink resistant to saturated sodium sulfide and preparation method thereof

A gravure printing ink and sodium sulfide technology, applied in ink, printing plate preparation, printing and other directions, can solve problems such as poor printing adaptability, and achieve enhanced first-line anti-counterfeiting function, good resistance to saturated sodium sulfide, and good physical and chemical resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of the aforementioned engraving gravure ink resistant to saturated sodium sulfide provided by the invention comprises the steps:

[0060] a. Stir and disperse polyurethane alkyd resin, isobenzene alkyd resin, pure phenolic resin, surfactant, wax, white carbon black, and some solvents, and roll them into base ink;

[0061] b. After adding optical variable anti-counterfeiting pigments, fluorescent trace markers, catalysts, and solvents, stir and disperse at high speed to obtain a product with a viscosity of (0.1-20) Pa·s (40°C, 300s) -1 ).

[0062] The engraving gravure ink resistant to saturated sodium sulfide of the invention can be used for printing.

Embodiment 1

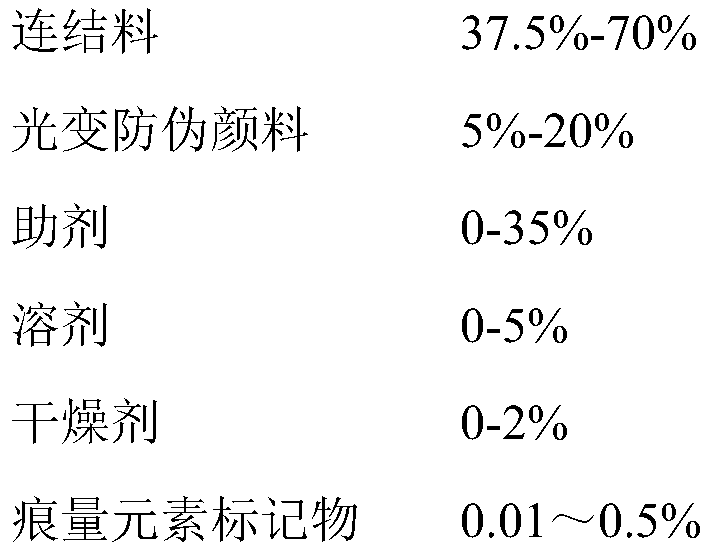

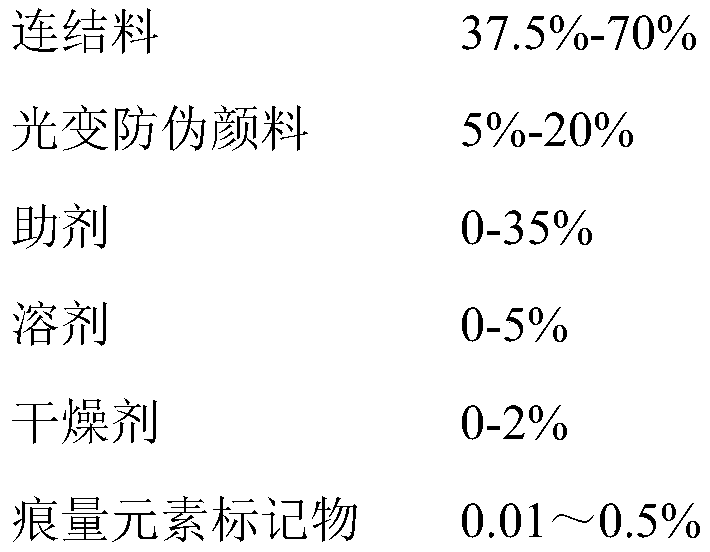

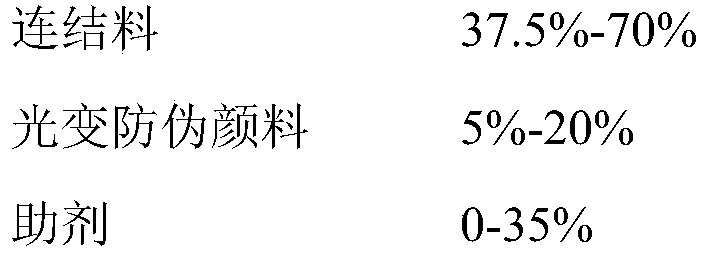

[0064] Inks are prepared according to the following composition:

[0065]

[0066] According to the above formula, the polyurethane alkyd resin linking material, m-benzene alkyd resin linking material, pure phenolic resin linking material, surfactant, wax, white carbon black, optical variable anti-counterfeiting pigment, desiccant, solvent are stirred and dispersed at high speed, rolled Make a white base for later use; add optically variable anti-counterfeiting pigments, fluorescent trace markers, white base, desiccant, and solvent, and then stir and disperse at high speed. After the ink is stable, test the viscosity and adjust it to a suitable range with a solvent. The optically variable anti-counterfeiting ink was prepared with a viscosity of 10Pa·s (40°C, on a flat plate, with a shear rate of 300s -1 ).

Embodiment 2

[0067] Embodiment 2 Resistance to saturated sodium sulfide test

[0068] The experimental ink prepared in Example 1 was compared with the comparative ink, which was selected from the inks described in Example 1 in Patent 201610130693.5. The specific formula is: 38.7% of acrylic modified polyester resin, 10% of isobenzene alkyd resin, 11% of rosin modified phenolic resin, 3% of dodecylbenzenesulfonate ammonium salt, 5% of caraba wax, silicon dioxide A300 5%, Zibianjin optical variable pigment 25%, mineral oil solvent D130 2%, non-cobalt iron-halogen azabicyclic macrocyclic iron complex 0.3%.

[0069] At 25°C, completely soak the experimental ink and comparative ink in a 100ml beaker filled with saturated sodium sulfide solution, and let it stand for 30 minutes. After taking it out, rinse it three times with tap water. After natural drying, compare with the standard sample for rating. The levels from low to high are 1-5 respectively.

[0070] The test result of the experimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com