Enzyme composition and its preparation method

An enzyme composition and technology for active substances, applied in the field of enzyme activity, can solve problems such as affecting enzyme activity, a large number of experiments, and complicated operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation of embodiment 1 cicada flower active substance (CAF)

[0036] Take the cicadae mycelium and inoculate it on the plate medium, cultivate it at 25°C for 18 days, then inoculate it into the Erlenmeyer flask, and cultivate it at 25°C for 7 days, and finally inoculate the cultured cicadae mycelium into the fermenter, and cultivate it at 25°C 3d, finally forming a fermentation liquid containing the active substance of cicadae, which is the fermentation liquid of cicadae mycelium.

[0037] The distilled fermented liquid of the active substance of cicada japonica was dried at 60° C. for 24 hours, then ground, and finally sieved through a 0.5 cm sieve to obtain CAF powder. Add 10mL, 100mmol / L sodium acetate buffer solution to every gram of CAF powder to obtain CAF suitable solution.

Embodiment 2

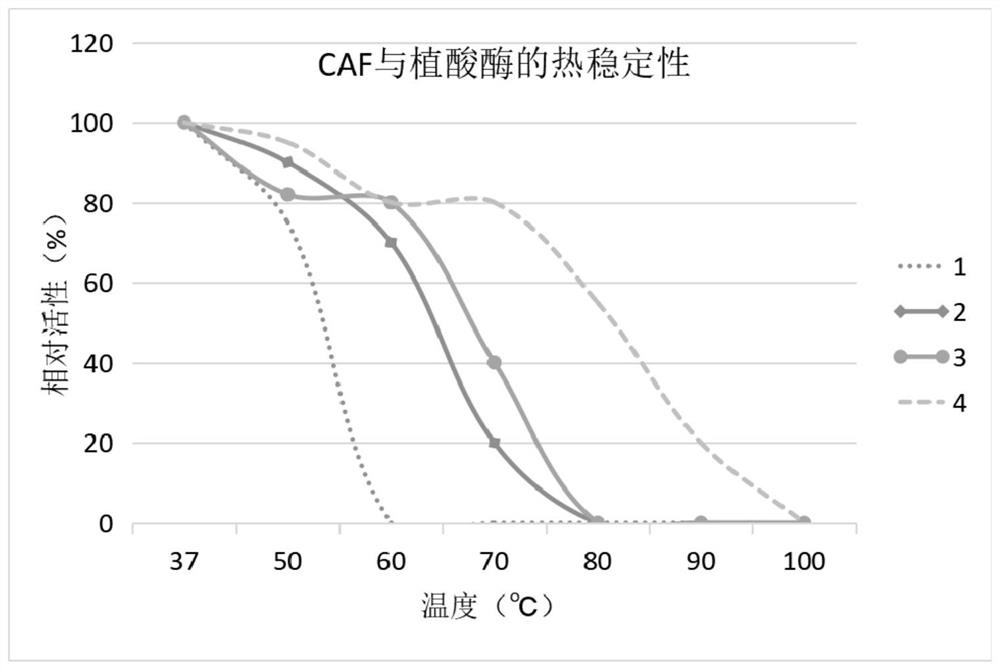

[0038] The test of embodiment 2 phytase thermostability

[0039] 1) Preparation and treatment of phytase CAF composition

[0040] Add 1 g of phytase to 4 mL of 100 mmol / L sodium acetate buffer to obtain a phytase solution. Get three parts of 1mL phytase solution, respectively add 2g, 5g, 10g of CAF powder prepared in Example 1 to obtain 1:2, 1:5, 1:10 phytase CAF composition, place it in the oven At 60°C, dry for 1 hour to obtain 1:2, 1:5, 1:10 phytase CAF composition test samples.

[0041] 2) Preparation and processing of the control composition

[0042] Add 1g of phytase to 4mL, 100mmol / L sodium acetate buffer to obtain a phytase solution, take 1mL of the phytase solution, place it in an oven, and dry it for 1 hour at 60°C to obtain a phytase control group sample .

[0043] 3) Phytase activity test

[0044] Take 1g of the phytase CAF composition test sample and the phytase control group sample and add 4mL, 100mmol / L sodium acetate buffer solution to make the test soluti...

Embodiment 3

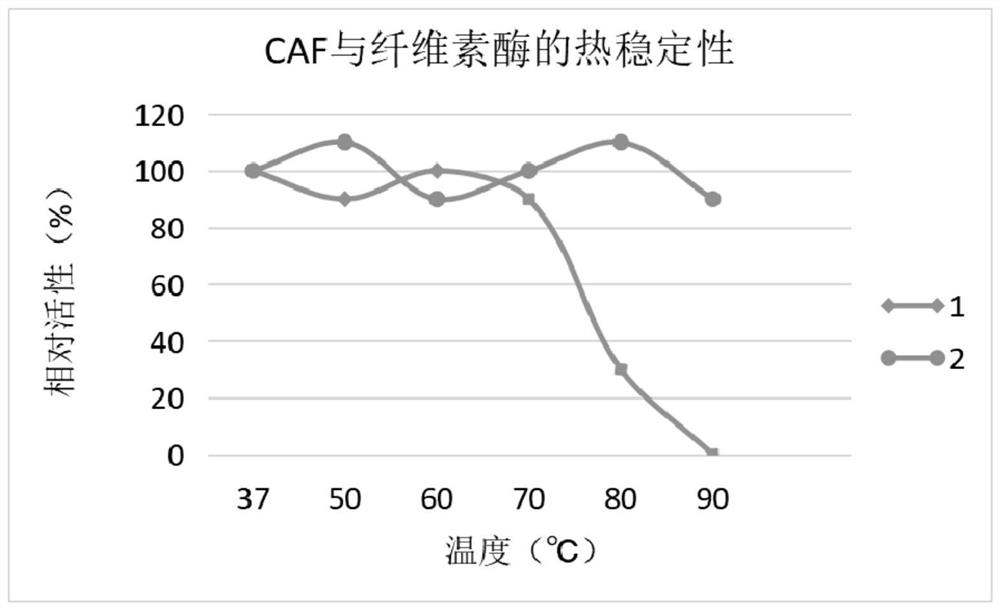

[0047] The test of embodiment 3 cellulase thermostability

[0048] 1) Preparation and treatment of cellulase CAF composition

[0049]Add 1 g of cellulase to 4 mL of 100 mmol / L sodium acetate buffer to obtain a cellulase solution. Take 1mL of cellulase solution, add 2g of CAF powder prepared in Example 1 to obtain a 1:2 cellulase CAF composition, place it in an oven, and dry it for 1 hour at 60°C to obtain a 1:2 Test samples of the cellulase CAF composition.

[0050] 2) Preparation and processing of the control composition

[0051] Add 1 g of cellulase to 4 mL of 100 mmol / L sodium acetate buffer to obtain a cellulase solution. Take 1mL of cellulase solution, place it in an oven, and dry it at 60°C for 1 hour to obtain the sample of cellulase control group.

[0052] 3) Cellulase activity test

[0053] Take 1g of the cellulase CAF composition test sample and the cellulase control group sample and add 4mL, 100mmol / L sodium acetate buffer solution to make the test solution, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com