Neutron diffraction characterization method for crystallization kinetic characteristics of bulk amorphous alloy

A technology of dynamic characteristics and amorphous alloys, which is applied in the use of wave/particle radiation for material analysis, scientific instruments, measuring devices, etc., can solve problems such as the inability to analyze microscopic crystallization mechanisms and atomic migration and diffusion laws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The test adopts the atomic percentage as Zr 48 Cu 36 Al 8 be 7 bulk amorphous alloys.

[0027]a. Select the nominal composition as Zr 48 Cu 36 Al 8 be 7 (at.%) bulk amorphous alloy as the object, obtained Φ5×100mm bulk amorphous alloy through vacuum arc melting (repeated smelting 5 times) and copper mold suction casting, and cut into Φ5×5mm alloy samples;

[0028] b. Place the sample in the neutron diffraction (wavelength 0.01nm) diffraction optical path for ex-situ isothermal crystallization treatment, the treatment temperature is 486°C, and the radiation data collection frequency is 3min;

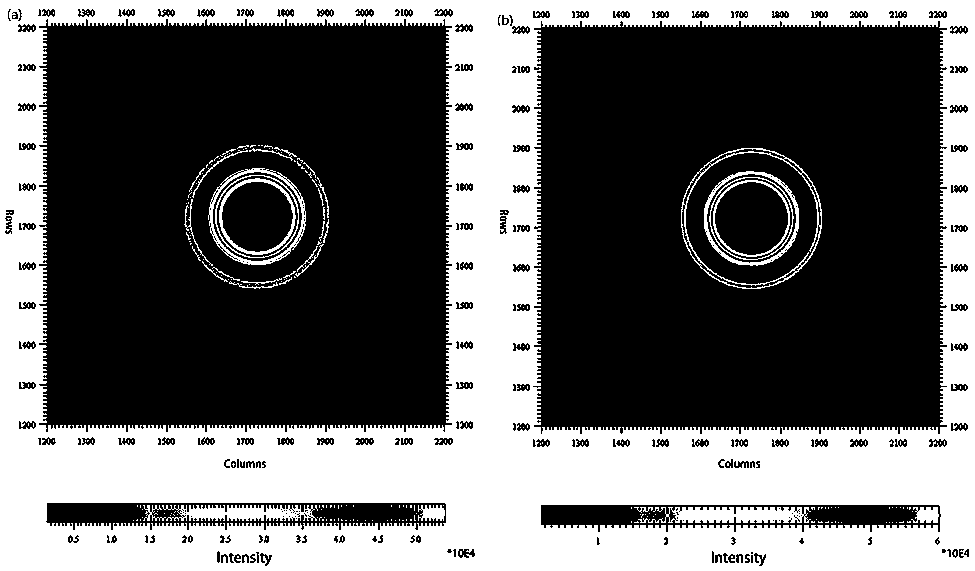

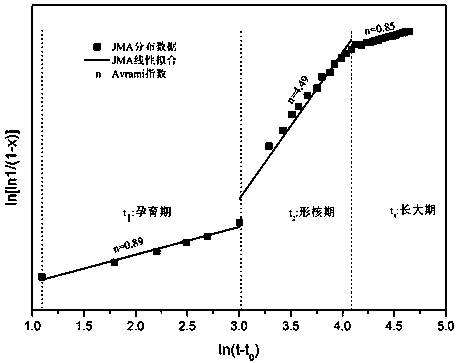

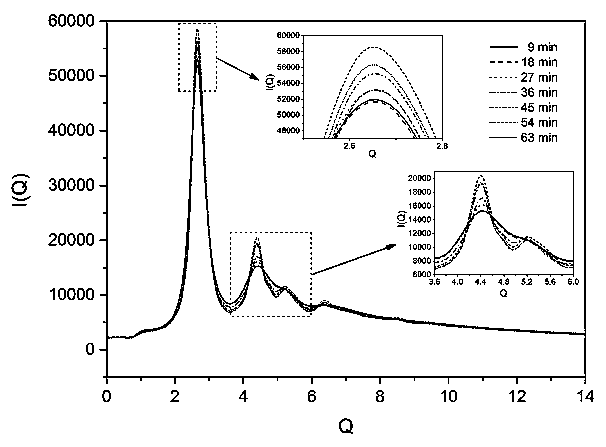

[0029] c. For the obtained diffraction data (see attached figure 1 , the figure is an example of in-situ neutron diffraction data with heat treatment time of 3min (a) and 54min (b) respectively) for correction and conversion to obtain the interference function I(Q) of the alloy (partial data), see attached figure 2 , the data points in the figure come from the experimenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com